Preparation method of nitrogen or metal doped carbon material

A metal doping, carbon material technology, applied in the preparation/purification of carbon, non-metallic elements, chemical instruments and methods, etc., can solve the problems of poor catalyst structure stability, low specific surface area, high preparation cost, and achieve good catalytic activity. , high activity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

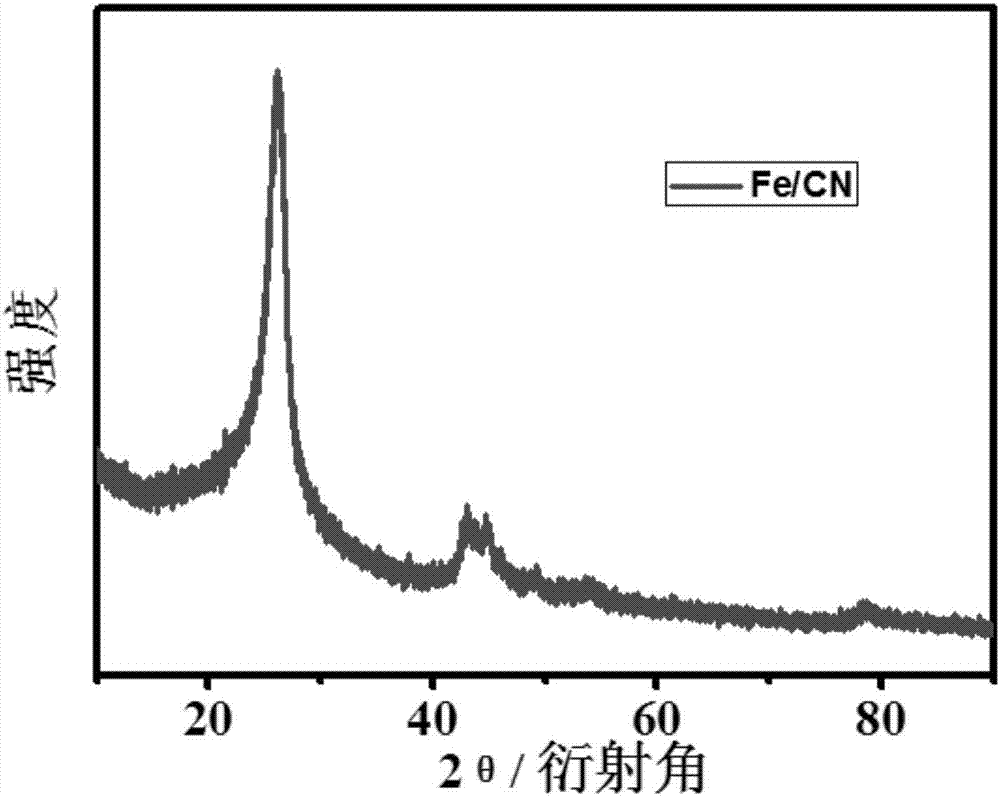

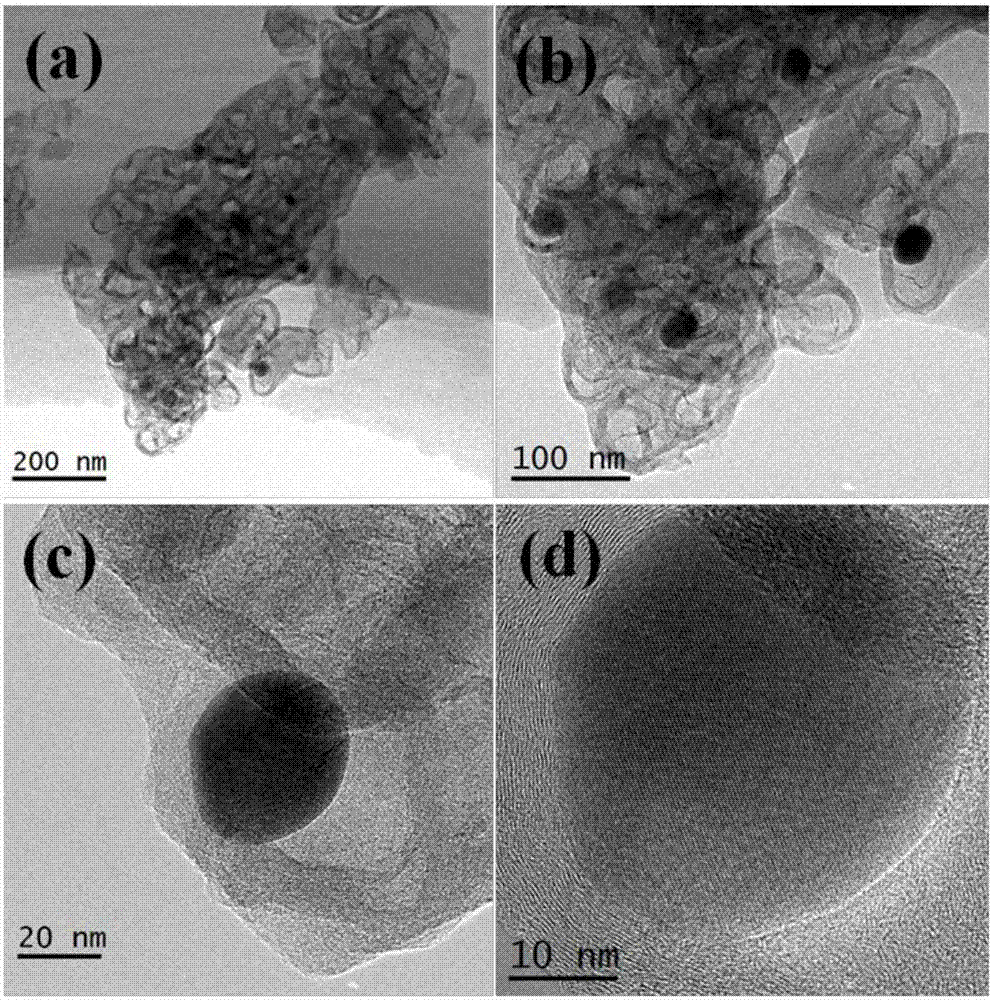

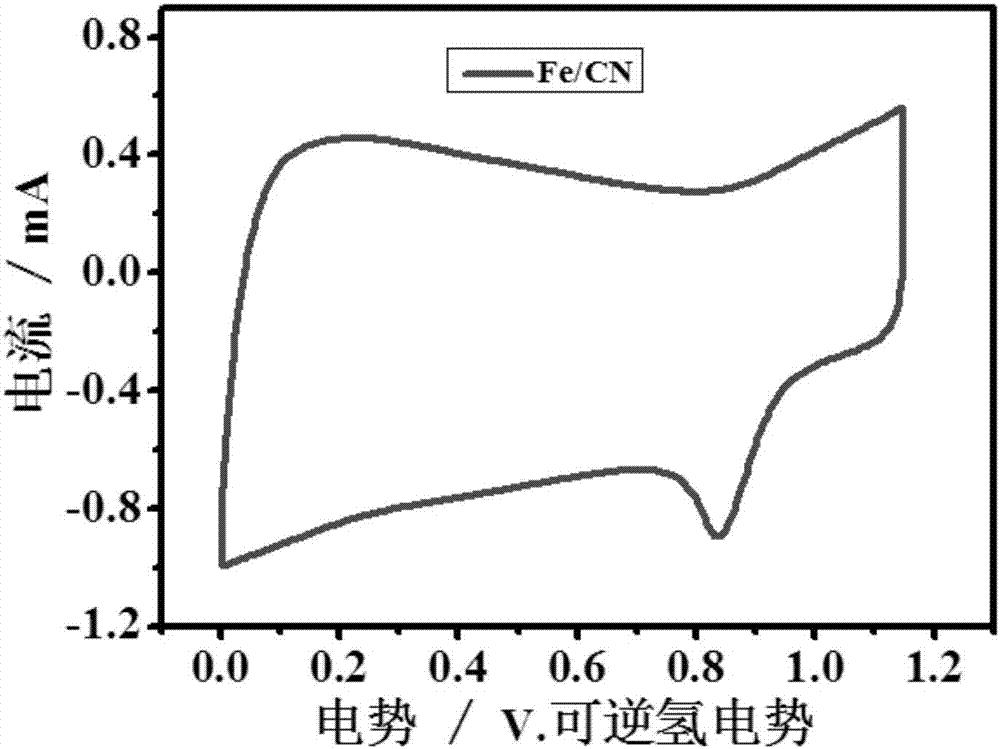

[0036] A method for preparing a metal-nitrogen-doped carbon material, the operation steps are as follows:

[0037] (1) Take 50ml of absolute ethanol solution and place it in a two-necked flask equipped with a condenser return tube, add 1mol of 2,6-diacetylpyridine, stir at room temperature for 10 minutes, then add 1mol of p-phenylenediamine, and stir at room temperature for 10 minutes , under the protection of nitrogen, after heating from room temperature to 100 °C, add 0.1 g of oxalic acid, and continue to stir for 24 hours. During the reaction, the acyl group and the amino group undergo dehydration condensation to form a multi-dentate iminopyridine ligand with metal ion complexing ability. Polymer, naturally cooled to room temperature;

[0038] (2) Take 0.5 mol of anhydrous ferrous chloride and dissolve it in 10ml of absolute ethanol. After the ferrous chloride is completely dissolved, add the 10ml of anhydrous ferrous chloride dissolved in anhydrous ethanol solution to the ...

Embodiment 2

[0043] A method for preparing a metal-nitrogen-doped carbon material, the operation steps are as follows:

[0044] (1) Take 50ml of n-butanol solution and place it in a two-necked flask equipped with a condenser return tube, add 1mol of 2,6-diacetylpyridine, stir at room temperature for 20 minutes, then add 1mol of melamine, stir at room temperature for 20 minutes, and Under the protection of air and gas, after heating from room temperature to 110 °C, add 0.1 g of oxalic acid, and continue to stir for 24 hours. During the reaction, the acyl group and the amino group undergo dehydration condensation to form a multi-dentate iminopyridine ligand polymerization with metal ion coordination ability. objects, naturally cooled to room temperature;

[0045] (2) Get 1mol of cobaltous chloride hexahydrate, be dissolved in 10ml n-butanol, until cobalt chloride is completely dissolved, one-time will be dissolved with the 10ml n-butanol solution that cobalt chloride is dissolved in the step...

Embodiment 3

[0050] A method for preparing a metal-nitrogen-doped carbon material, the operation steps are as follows:

[0051] (1) Take 50ml of absolute ethanol solution and place it in a two-necked flask equipped with a condensing return tube, add 1mol of 2,6-diacetylpyridine, stir at room temperature for 10 minutes, and then add 2,4-diamino-6-methanol 1 mol of 1,3,5-triazine, stirred at room temperature for 10 minutes, heated from room temperature to 50°C under nitrogen protection, added 0.1 g of oxalic acid, and continued to stir for 24 hours. During the reaction, the acyl group and the amino group were dehydrated and condensed , forming a multi-dentate iminopyridine ligand polymer with metal ion complexing ability, and naturally cooling to room temperature;

[0052] (2) get anhydrous nickel chloride 0.5mol g, be dissolved in 10ml dehydrated alcohol, treat that nickel chloride dissolves completely completely, disposable will be dissolved with the 10ml dehydrated alcohol solution of anh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com