Facultative anaerobic fermentation fungicide and method for preparing organic fertilizer through facultative anaerobic fermentation fungicide

A technology of facultative fermentation and manufacturing method, applied in the field of manufacturing organic fertilizer and facultative fermentation inoculum, can solve the problems of slow decomposition of organic matter, short composting cycle, soil pollution, etc., and achieve the effects of increasing content, complete functions and stable state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

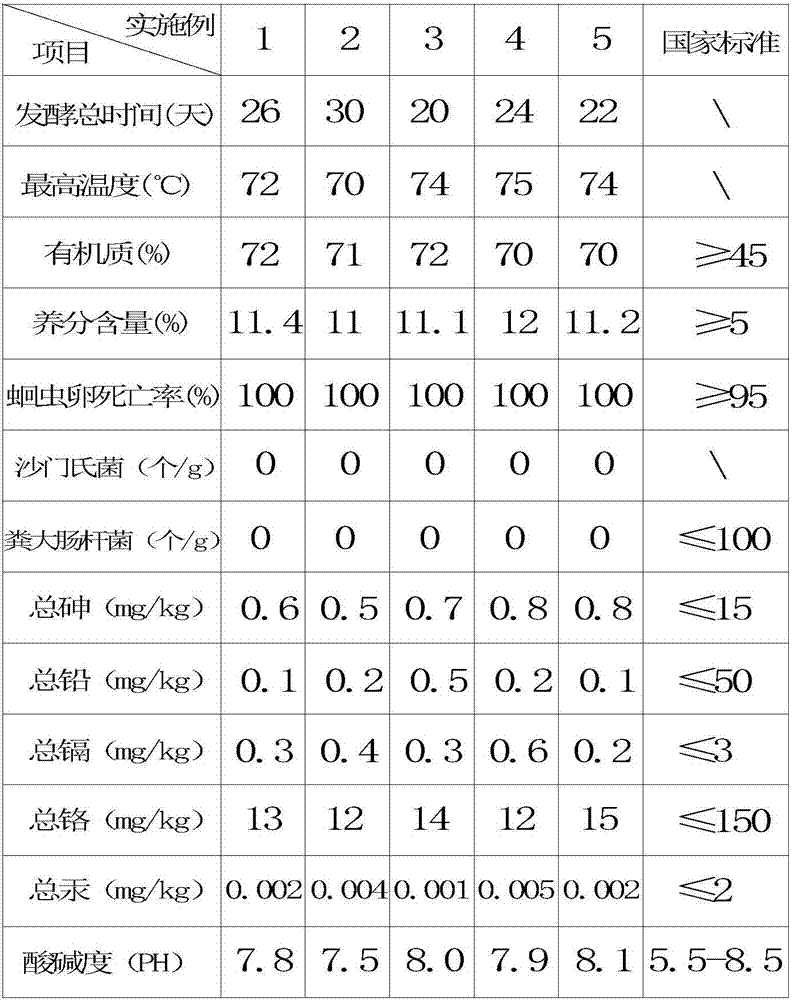

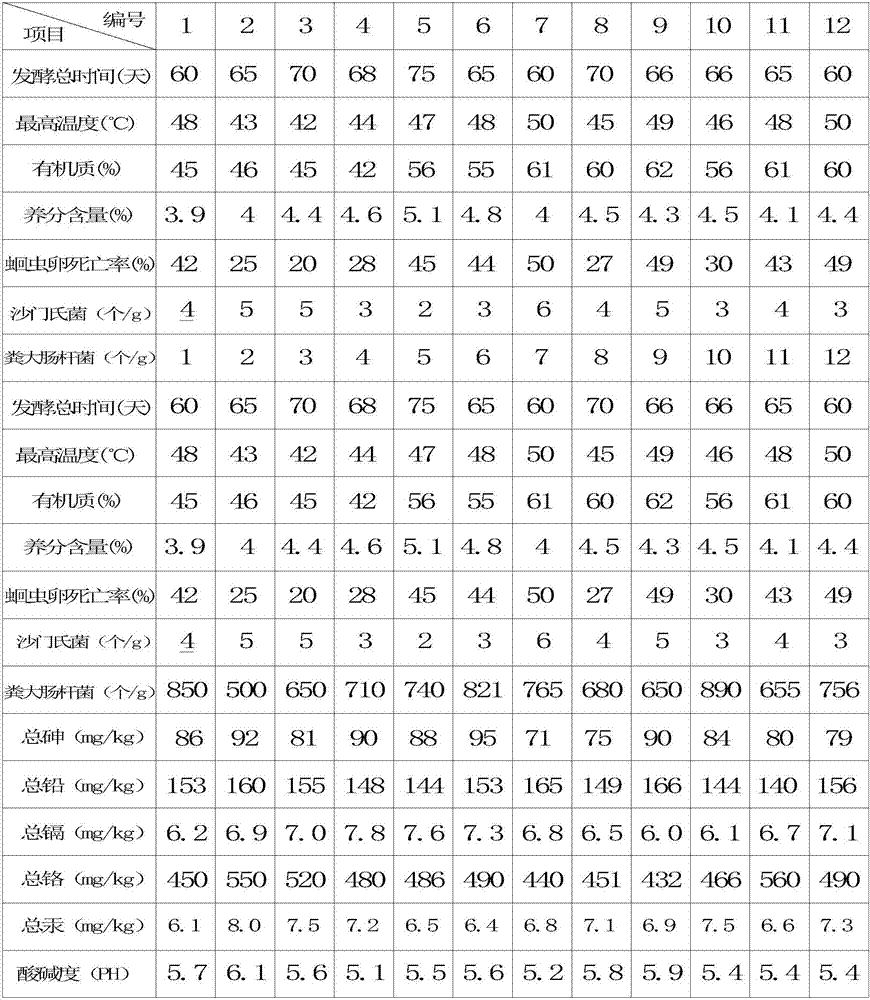

Embodiment 1

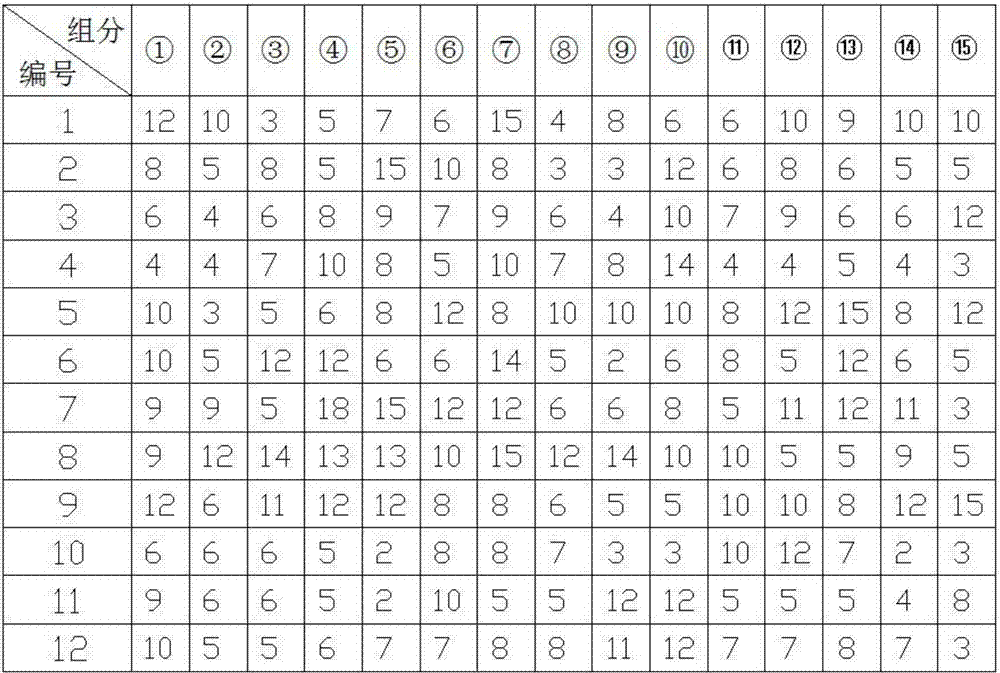

[0053] Preparation of aerobic fermentation agent:

[0054] Weigh 9 parts of lactic acid bacteria, 3 parts of Lactobacillus acidophilus, 7 parts of Bacillus subtilis, 14 parts of Bacillus licheniformis, 12 parts of Bacillus coagulans, 7 parts of Aspergillus oryzae, 15 parts of Bacillus megaterium, 8 parts of Bacillus lateralis, thuringiensis 5 parts of Bacillus, 13 parts of Streptococcus faecalis, 6 parts of photosynthetic bacteria, 5 parts of saccharomyces, 7 parts of Paecilomyces lilacinus, 7 parts of nitrogen-fixing bacteria, and 4 parts of actinomycetes; warm water, then add the weighed partaerobic fermentation flora into the warm water dissolved with brown sugar, continue to add 40 ℃ warm water after mixing, until the mass fraction of warm water with brown sugar and facultative fermentation flora reaches 1000 parts, and then Add 1300 parts of rice bran and 400 parts of wheat bran, mix well and then seal it, and obtain the facultative fermentation bacterial agent after 4 da...

Embodiment 2

[0058] Preparation of aerobic fermentation agent:

[0059] Weigh 8 parts of lactic acid bacteria, 2 parts of Lactobacillus acidophilus, 8 parts of Bacillus subtilis, 15 parts of Bacillus licheniformis, 13 parts of Bacillus coagulans, 6 parts of Aspergillus oryzae, 14 parts of Bacillus megaterium, 10 parts of Bacillus lateralis, thuringiensis 4 parts of Bacillus, 14 parts of Streptococcus faecalis, 5 parts of photosynthetic bacteria, 6 parts of saccharomyces, 6 parts of Paecilomyces lilacinus, 8 parts of nitrogen-fixing bacteria, and 4 parts of actinomycetes for use; take 20 parts of brown sugar and dissolve them in 42°C warm water, then add the weighed partaerobic fermentation flora into the warm water dissolved with sucrose, and continue to add 42 ℃ warm water after mixing until the mass fraction of warm water with brown sugar and facultative fermentation flora reaches 1200 parts, and then Add 1600 parts of rice bran and 300 parts of wheat bran, mix thoroughly and then seal, ...

Embodiment 3

[0063] Preparation of aerobic fermentation agent:

[0064] Weigh 10 parts of lactic acid bacteria, 4 parts of Lactobacillus acidophilus, 6 parts of Bacillus subtilis, 12 parts of Bacillus licheniformis, 9 parts of Bacillus coagulans, 9 parts of Aspergillus oryzae, 16 parts of Bacillus megaterium, 7 parts of Bacillus lateralis, thuringiensis 6 parts of Bacillus, 12 parts of Streptococcus faecalis, 7 parts of photosynthetic bacteria, 4 parts of saccharomyces, 8 parts of Paecilomyces lilacinus, 5 parts of nitrogen-fixing bacteria, and 5 parts of actinomycetes for use; take 20 parts of brown sugar and dissolve them in 38°C Warm water, then add the weighed partaerobic fermentation flora into the warm water dissolved with maltose, continue to add 38 ℃ warm water after mixing, until the mass fraction of warm water with brown sugar and facultative fermentation flora reaches 700 parts, and then Add 1000 parts of rice bran and 500 parts of wheat bran, mix thoroughly and then seal, and obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com