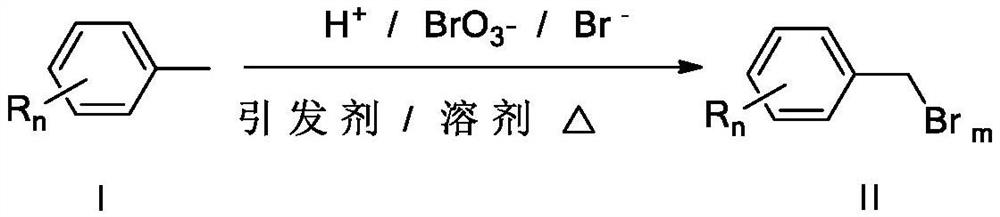

A kind of preparation method of benzyl bromide

A technology of benzyl bromide and benzyl, which is applied in the field of preparation of benzyl bromide, can solve problems such as narrow application range, large substrate limitation, and limited substrate, so as to broaden the application range, wide application range, and increase the rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

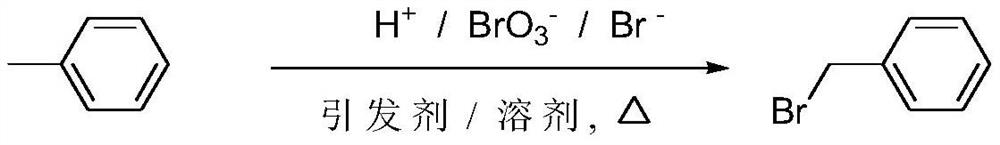

Embodiment 1

[0035] Toluene (3.7g, 40mmol), sodium bromate (2.1g, 14mmol), sodium bromide (2.9g, 28mmol), dichloromethane (25mL) were added to the tank equipped with stirring, reflux condenser, thermometer and tail gas absorption device In the reaction flask, heat to reflux, quickly add 1 / 3 of the total volume of the initiator solution (0.025g AIBN, 0.025gBPO dissolved in 5mL dichloromethane), slowly add sulfuric acid (2.1g, 21mmol concentrated sulfuric acid with 2.5mL water Dilute the obtained) and the remaining initiator solution, track by gas chromatography, after the reaction is complete, cool to room temperature, add saturated sodium bisulfite solution (10mL), stir until the red color fades, let stand, separate liquid, and use Dichloromethane was extracted twice (10mL×2), the organic phases were combined and washed with saturated sodium chloride solution, dried, concentrated, and the crude product was purified by column chromatography (the elution solvent was petroleum ether) to obtain...

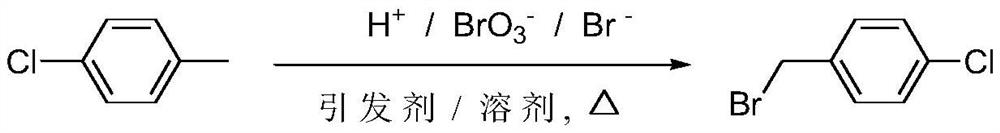

Embodiment 2

[0038] p-Chlorotoluene (5.1g, 40mmol), sodium bromate (2.1g, 14mmol), sodium bromide (2.9g, 28mmol), dichloromethane (25mL) were added to the equipment equipped with stirring, reflux condenser, thermometer and tail gas absorption In the reaction bottle of the device, heat to reflux, quickly add 1 / 3 of the total volume of the initiator solution (0.025g AIBN, 0.025g BPO are dissolved in 5mL dichloromethane to obtain), slowly add sulfuric acid (2.1g, 21mmol concentrated sulfuric acid is used 2.5mL of water to dilute the obtained) and the remaining initiator solution, tracked by gas chromatography, after the reaction is complete, cool to room temperature, add saturated sodium bisulfite solution (10mL), stir until the red color fades, let stand, separate liquid, The aqueous phase was extracted twice with dichloromethane (10 mL×2), and the combined organic phases were washed with saturated sodium chloride solution, dried, concentrated, and the crude product was recrystallized from et...

Embodiment 3

[0041] Add o-chlorotoluene (5.1g, 40mmol), sodium bromate (2.5g, 16.7mmol), sodium bromide (3.5g, 33.6mmol), 1,2-dichloroethane (30mL) In the reaction flask of the condenser tube, thermometer and tail gas absorption device, heat to reflux, and quickly add 1 / 3 of the total volume of the initiator solution (0.05g AIBN, 0.05g BPO dissolved in 10mL 1,2-dichloroethane to obtain), Slowly add sulfuric acid (2.5g, 25.2mmol concentrated sulfuric acid diluted with 2.5mL water) and the remaining initiator solution dropwise, track by gas chromatography, after the reaction is complete, cool to room temperature, add saturated sodium bisulfite solution (10mL ), stirred until the red color faded, stood still, separated, the aqueous phase was extracted twice with 1,2-dichloroethane (10mL×2), the combined organic phase was washed with saturated sodium chloride solution, dried, concentrated, and the crude product After purification by column chromatography (petroleum ether as the elution solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com