Method for preparing low-grade aliphatic amine from light alkane through bromination-ammonolysis

A technology for low-carbon alkanes and aliphatic amines, which is applied in the field of low-carbon alkanes to prepare low-grade aliphatic amines through bromination-ammonolysis, which can solve the problems of high price, low product purity, and high raw material cost, and achieve reduced reaction costs and single-pass conversion. High, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

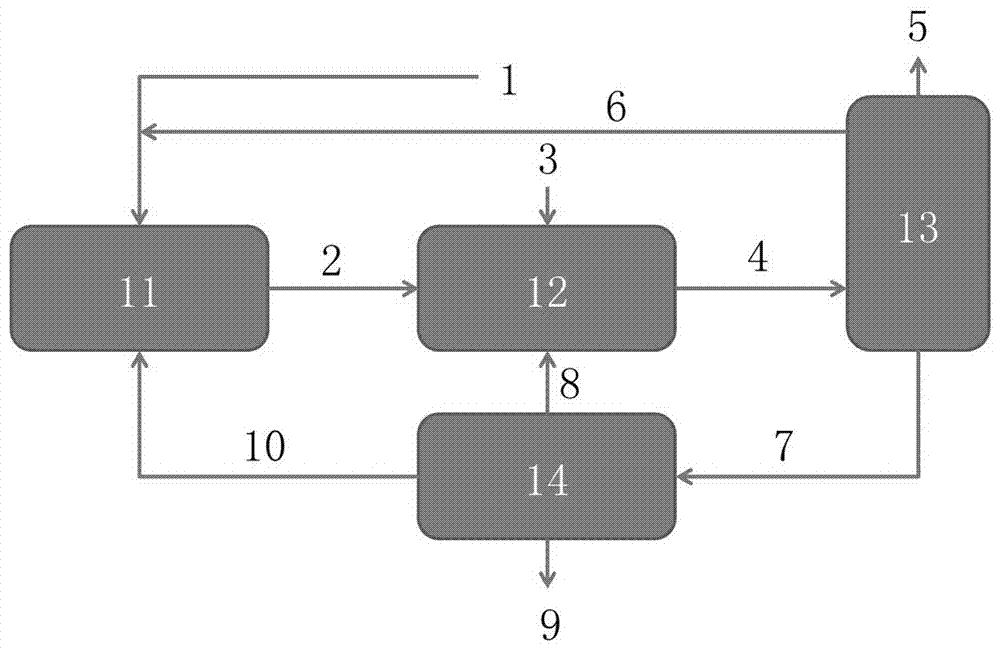

[0029] 1. A method for preparing lower aliphatic amines through bromination-ammonolysis of lower carbon alkanes (the flow chart is as follows: figure 1 shown), including the following steps:

[0030] (1) Bromination reaction: CH with a purity > 90% 4 As feed gas, according to CH 4 , The volume ratio of bromine gas is 1:1, CH 4 Mixed with bromine gas, the bromination reaction is carried out in a fixed bed reactor (bromination unit), wherein the fixed bed reactor is filled with a loaded metal oxyhalide TaOF 3 / Al 2 o 3 , reaction temperature 450°C, pressure 0.5MPa, feed gas space velocity 5000h -1 , generating methyl bromide and hydrogen bromide;

[0031] (2) Ammonolysis reaction: pump the product of step (1) into the liquid phase reaction tank, which is filled with ammonia water, spray the ammonia solution through the spray circulation device to control the pH of the system>8, and the reaction temperature is 20°C, pressure 1MPa, generate aqueous solution of aliphatic ami...

Embodiment 2

[0036] 1. a kind of method that lower alkane prepares lower aliphatic amine through bromination-ammonolysis, comprises the following steps:

[0037] (1) Bromination reaction: C with a purity > 95% 2 h 6 As feed gas, according to C 2 h 6 , The volume ratio of bromine gas is 1:2, and C 2 h 6 Mixed with bromine gas, the bromination reaction is carried out in a fixed bed reactor (bromination unit), where the fixed bed reactor is filled with a supported non-stoichiometric metal oxyhalide FeO x Br y / Al 2 o 3(wherein, 2x+y=3, x>0, y>0), the reaction temperature is 400°C, the pressure is 0.1MPa, and the space velocity of raw material gas is 6000h -1 , generating ethyl bromide and hydrogen bromide;

[0038] (2) Ammonolysis reaction: pump the product of step (1) into the liquid phase reaction tank, which is filled with ammonia water, spray the ammonia solution through the spray circulation device to control the pH of the system>8, and the reaction temperature is 60°C, pressur...

Embodiment 3

[0043] 1. a kind of method that lower alkane prepares lower aliphatic amine through bromination-ammonolysis, comprises the following steps:

[0044] (1) Bromination reaction: C with a purity > 90% 3 h 8 As feed gas, according to C 3 h 8 , The volume ratio of bromine gas is 2:1, and C 3 h 8 Mixed with bromine gas, the bromination reaction is carried out in a fixed bed reactor (bromination unit), wherein the fixed bed reactor is filled with supported metal oxyhalide ZrOF 2 / Al 2 o 3 , reaction temperature 300°C, pressure 1MPa, feed gas space velocity 2000h -1 , generating bromopropane and hydrogen bromide;

[0045] (2) Ammonolysis reaction: pump the product of step (1) into the liquid phase reaction tank, which is filled with ammonia water, spray the ammonia solution through the spray circulation device to control the pH of the system>8, and the reaction temperature is At 40°C and a pressure of 0.5MPa, an aqueous solution of a fatty amine mixture and an aqueous solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com