Preparation method of universal chip for detection of protein and nucleic acid by time-of-flight mass spectrometry

A time-of-flight mass spectrometry and chip technology, which is applied in the field of mass spectrometry detection, can solve the problems of low signal-to-noise ratio, single application field, and inability to detect nucleic acid samples across borders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Embodiment 1, microarray chip surface hydrophilic treatment

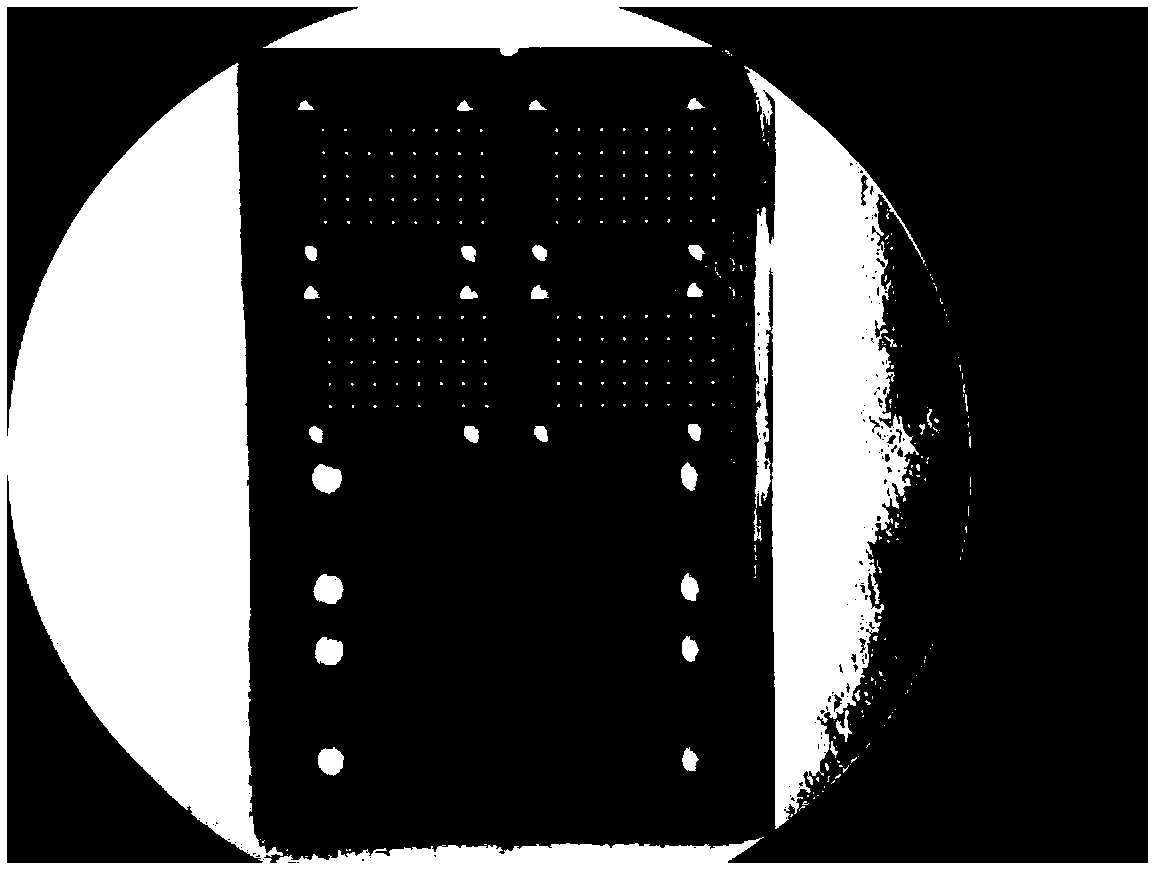

[0097] The main feature of the chip is tough texture and good flatness; diamond, single crystal silicon, quartz crystal, etc.; divided into a sheet structure suitable for the size of the surface unit of the chip adapter, the thickness of the chip is 0.5-1.8mm, in order to ensure the accuracy of quality inspection, the surface of the chip The flatness is less than 10μm. For example, a single crystal silicon wafer is selected as the base of the microarray chip, and silicon dioxide oxide films, zinc oxide films, and aluminum oxide films can be fired and grown on the surface of the silicon wafer structure, with a thickness of 150-800nm, preferably 500nm. Water-based, using thermal oxidation process.

[0098] Such as image 3 As shown, the steps of using a thermal oxidation device to burn and grow a silicon dioxide oxide film are as follows:

[0099] ① Place the silicon wafer in a reaction tube made of quartz g...

Embodiment 2

[0107] Embodiment 2, microarray chip surface hydrophobic treatment

[0108] 1. Sealing treatment of hydrophilic spotting hole area

[0109] Clean residual organic matter on the surface of the chip: first pass the oxygen flow rate of 60-140ml / min, the power of 100-300W, and the treatment time of 1-10min; Thoroughly cleansed and hydroxylated.

[0110] Photoresist technology to seal the sample hole area: Spin the photoresist on the treated substrate by spin coating, the spin coating speed is 1000 ~ 8000rpm, and then place it under the photolithography mask plate, in the 390nm ultraviolet After being exposed to light for 20s~5min, it is eluted with the corresponding developer, so as to construct the spotting hole area with an ordered structure. The photoresist uses acid-resistant polymethyl methacrylate (PMMA) and / or polystyrene.

[0111] 2. Hydrophobic treatment of the outer area of the microarray chip hole

[0112] The process of surface treatment of metal or non-metal mat...

Embodiment 3

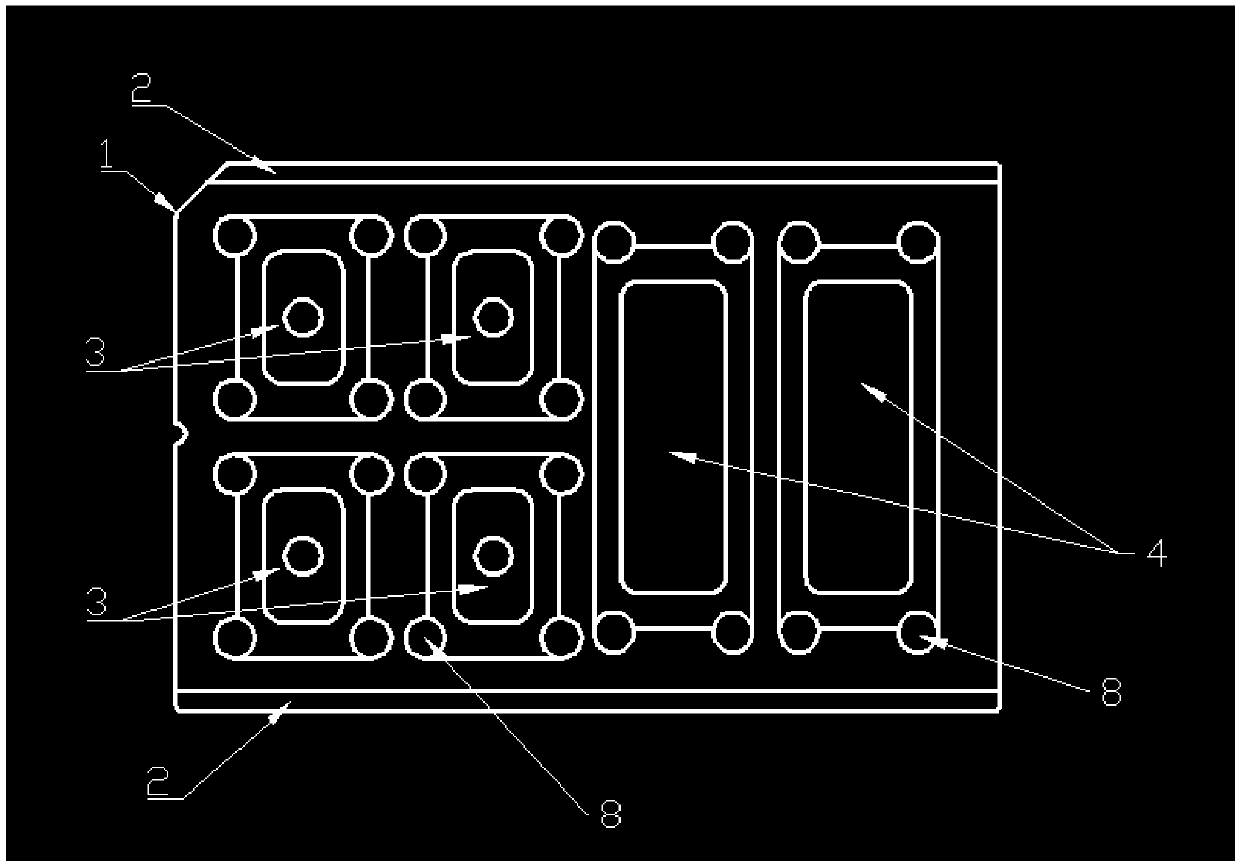

[0137] Example 3: Crystallization comparison between microarray dual-purpose chip and traditional chip

[0138] Select the same protein or nucleic acid sample, and take an appropriate amount of the corresponding matrix solution and drop them on the dual-purpose chip and the traditional chip respectively. After the matrix is naturally dried, observe the crystal form under the microscope.

[0139] Such as Figure 5 As shown, the crystal form of the traditional biological detection chip (left picture) is irregular, the thickness is uneven, and it is in the shape of a coffee ring, with a hollow center and thick surroundings. However, the microarray chip provided by the present invention has regular crystal morphology (right picture), uniform thickness, and fine crystal growth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com