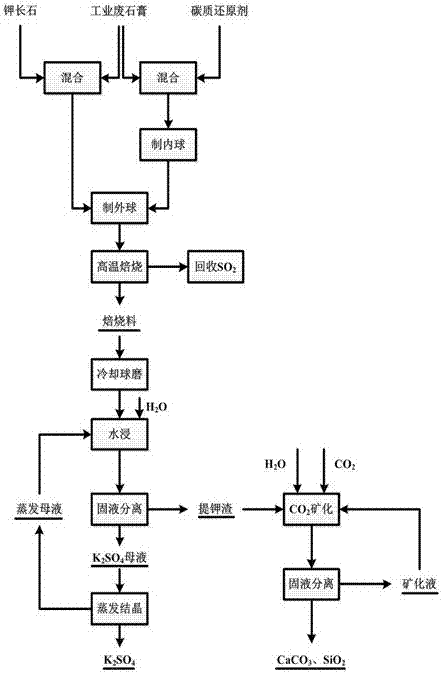

Industrial method for co-producing potassium sulfate and sulfur dioxide through CO2 mineralization by using potassium feldspar-waste gypsum

A technology of sulfur dioxide and industrial methods, applied in chemical instruments and methods, alkali metal sulfite/sulfite, solid waste removal, etc., can solve problems such as burning loss, achieve simple process operation, easy promotion and use, and reduce The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Put titanium gypsum with a calcium sulfate content of 70 wt.% and a particle size of 75 μm and coal powder with a fixed carbon content of 60 wt.% and a particle size of 200 μm into a planetary wheel mill mixer to control the balance between calcium sulfate and carbon The molar ratio is 1:1, and the uniformly mixed materials are sent into the 1 # silo;

[0029] (2) The potassium feldspar with a potassium oxide content of 8 wt.% was crushed and ground to 75um and titanium gypsum was put into a planetary wheel mill mixer, and the mass ratio of potassium feldspar to calcium sulfate was controlled to be 1:1. The uniformly mixed material is sent into the 2 # silo;

[0030] (3) Put the mixed material obtained in step (1) into the inner ball disc pelletizing machine, and spray water into the pelletizing machine at the same time;

[0031] (4) Screen the inner ball obtained in step (3), and put the inner ball with a diameter of 4mm into the outer ball disc pelletizer, put ...

Embodiment 2

[0040] (1) Put phosphogypsum with a calcium sulfate content of 83 wt.% and a particle size of 35 μm and coal powder with a fixed carbon content of 65 wt.% and a particle size of 100 μm into a planetary wheel mill mixer, and control the molar ratio of calcium sulfate to carbon as 1:2, the uniformly mixed material is sent into 1 through the screw propeller # silo;

[0041] (2) The potassium feldspar with a potassium oxide content of 10 wt.% was crushed and ground to 150um and desulfurized gypsum was put into a planetary wheel mill mixer, and the mass ratio of potassium feldspar to calcium sulfate was controlled to be 1:2. The uniformly mixed material is sent into the 2 # silo;

[0042] (3) Put the mixed material obtained in step (1) into the inner ball disc pelletizing machine, and spray water into the pelletizing machine at the same time;

[0043] (4) Screen the inner ball obtained in step (3), and put the inner ball with a diameter of 6 mm into the outer ball disc pelletize...

Embodiment 3

[0052] (1) Put desulfurized gypsum with a calcium sulfate content of 95 wt.%, a particle size of 75 μm, and coke with a fixed carbon content of 80 wt.%, and a particle size of 150 μm into a planetary wheel mill mixer, and control the molar ratio of calcium sulfate and carbon to 1 : 3, the uniformly mixed material is sent into 1 through the screw propeller # silo;

[0053] (2) Put the potassium feldspar with a potassium oxide content of 13 wt.% into a planetary wheel mill mixer by crushing and grinding it to 150um and desulfurization gypsum, and control the mass ratio of potassium feldspar and calcium sulfate to 1:3. The uniformly mixed material is sent into the 2 # silo;

[0054] (3) Put the mixed material obtained in step (1) into the inner ball disc pelletizing machine, and spray water into the pelletizing machine at the same time;

[0055] (4) Screen the inner ball obtained in step (3), and put the inner ball with a diameter of 5mm into the outer ball disc pelletizer, pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com