Continuous electron ion fast conducting type double perovskite magnesium ion battery cathode material and preparation method thereof

A magnesium-ion battery and double perovskite technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex matrix action mechanism, shorten the diffusion time of magnesium ions, and material lattice transformation, so as to accelerate the migration ability and The rate of redox reaction, the effect of reducing electron migration resistance and improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

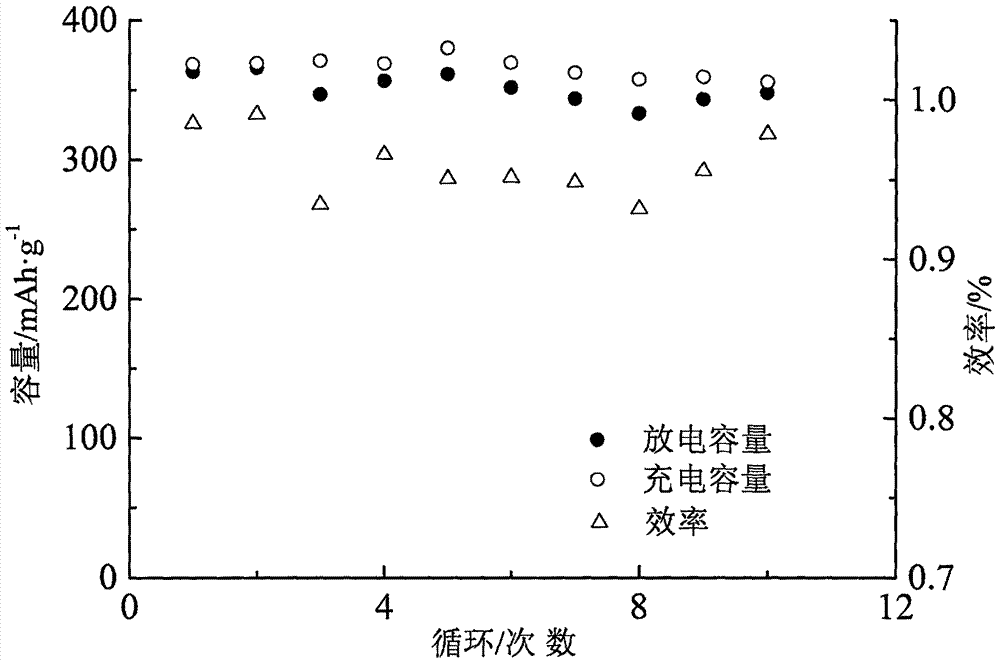

Image

Examples

Embodiment 1

[0021] Embodiment 1: Magnesium nitrate hexahydrate, lithium nitrate, tetrabutyl titanate, strontium nitrate, lanthanum nitrate hexahydrate, yttrium nitrate hexahydrate, copper nitrate trihydrate, zinc nitrate hexahydrate, niobium oxalate according to the stoichiometric formula Mg 0.8 Sr 0.2 La 0.5 Y 0.2 Li 0.3 Ti 0.8 Cu 0.1 Zn 0.1 NbO 6 Mix, add citric acid whose amount is 5.0 times of the total metal ion substance, add water and stir evenly to form a total metal ion concentration of 1.0mol L -1 The initial aqueous solution; mix and dissolve 6g acrylamide / 100mL water volume of acrylamide and 1g N,N'-methylenebisacrylamide / 100mL water volume N,N'-methylenebisacrylamide and water, and the acrylamide in the solution The amount of the substance is 0.5 times the amount of the total metal ion substance in the initial aqueous solution; use a polytetrafluoroethylene stirring paddle to stir at a speed of 1500rpm for 5 minutes, then raise it to 75°C at a speed of 5°C / min and main...

Embodiment 2

[0022] Embodiment 2: Magnesium nitrate hexahydrate, lithium nitrate, tetrabutyl titanate, strontium nitrate, lanthanum nitrate hexahydrate, yttrium nitrate hexahydrate, copper nitrate trihydrate, zinc nitrate hexahydrate, niobium oxalate according to the stoichiometric formula Mg 0.8 Sr 0.2 La 0.5 Y 0.2 Li 0.3 Ti 0.8 Cu 0.1 Zn 0.1 NbO 6 Mix, add citric acid whose amount is 7 times the amount of total metal ion substances, add water and stir evenly to form a total metal ion concentration of 1.5mol L -1 The initial aqueous solution; mix and dissolve 6g acrylamide / 100mL water volume of acrylamide and 1g N,N'-methylenebisacrylamide / 100mL water volume N,N'-methylenebisacrylamide and water, and the acrylamide in the solution The amount of the substance is 0.7 times the amount of the total metal ion substance in the initial aqueous solution; use a polytetrafluoroethylene stirring paddle to stir at a speed of 1700rpm for 10 minutes, then raise it to 80°C at a speed of 8°C / min a...

Embodiment 3

[0023] Embodiment 3: Magnesium nitrate hexahydrate, lithium nitrate, tetrabutyl titanate, strontium nitrate, lanthanum nitrate hexahydrate, yttrium nitrate hexahydrate, copper nitrate trihydrate, zinc nitrate hexahydrate, niobium oxalate according to the stoichiometric formula Mg 0.8 Sr 0.2 La 0.5 Y 0.2 Li 0.3 Ti 0.8 Cu 0.1 Zn 0.1 NbO 6 Mix, add citric acid whose amount is 10.0 times of the total metal ion substance, add water and stir evenly to form a total metal ion concentration of 2.5mol L -1 The initial aqueous solution; mix and dissolve 6g acrylamide / 100mL water volume of acrylamide and 1g N,N'-methylenebisacrylamide / 100mL water volume N,N'-methylenebisacrylamide and water, and the acrylamide in the solution The amount of the substance is 1.2 times the amount of the total metal ion substance in the initial aqueous solution; use a polytetrafluoroethylene stirring paddle to stir at a speed of 2000rpm for 15 minutes, then raise it to 85°C at a speed of 9°C / min and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com