A kind of heparinized bacterial nanocellulose/chitosan composite tube and its preparation method and application

A technology of nanocellulose and chitosan, applied in pharmaceutical formulations, transportation and packaging, packaged food, etc., can solve the problem of decreased anticoagulant activity of heparin, it is difficult to achieve long-term maintenance of heparinization effect, and it is difficult to work for a long time, etc. problem, to achieve the effect of enhanced anticoagulant activity, enhanced anticoagulant activity, and favorable adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

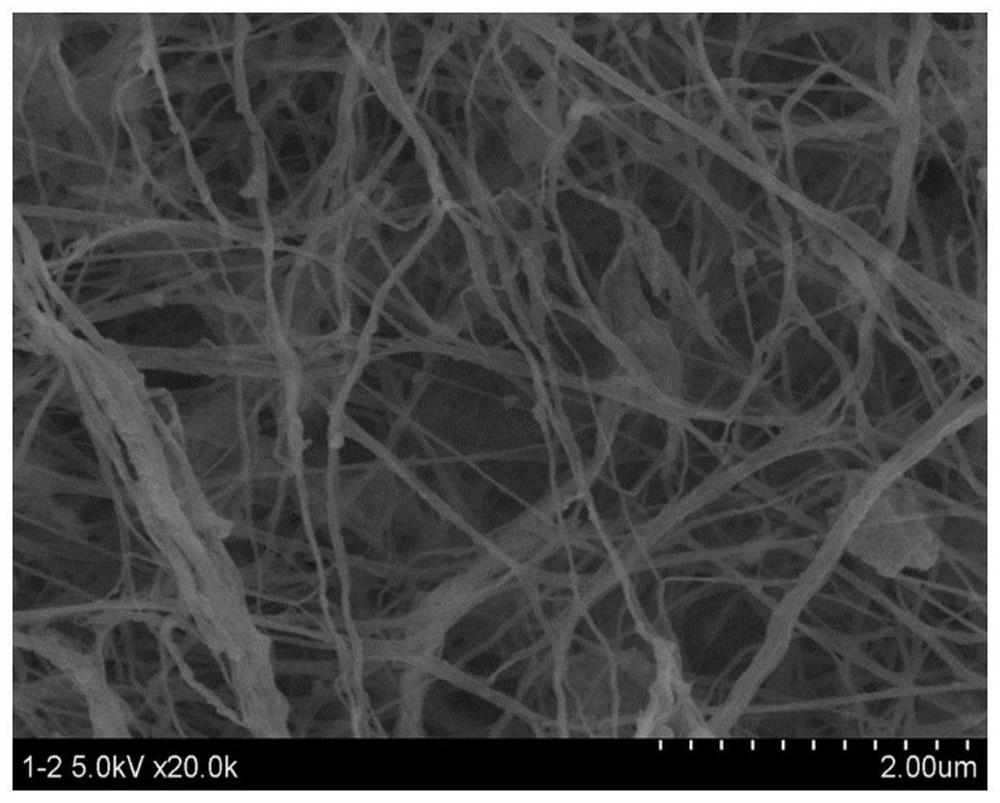

[0049] (1) Obtain a BNC tube with an inner diameter of 3mm, an outer diameter of 8mm, and a length of 50mm by in-situ static culture, place it in 1% NaOH solution, 80°C, water bath for 4h, and then replace it repeatedly with ultrapure water to Neutrals are obtained from preconditioned BNC tubing.

[0050] (2) 100 mL of 1% acetic acid solution was prepared with ultrapure water, and 0.1 g of chitosan was dissolved in the acetic acid solution. Place the BNC tube sleeve obtained in step (1) on a silicone tube with an outer diameter of 3mm in the acetic acid solution of chitosan, 30°C, 100rpm, shake in a water bath for 12h, then immerse in 1% NaOH solution and let stand for 4h. Then it was washed and replaced repeatedly to neutrality with ultrapure water to obtain the bacterial nanocellulose / 0.1% chitosan BNC / 0.1% CH composite tube.

[0051] (3) Place the BNC / 0.1% CH composite tube obtained in step (2) in 0.05M MES buffer solution with pH=5.5, shake in a water bath at 30° C. at 10...

Embodiment 2

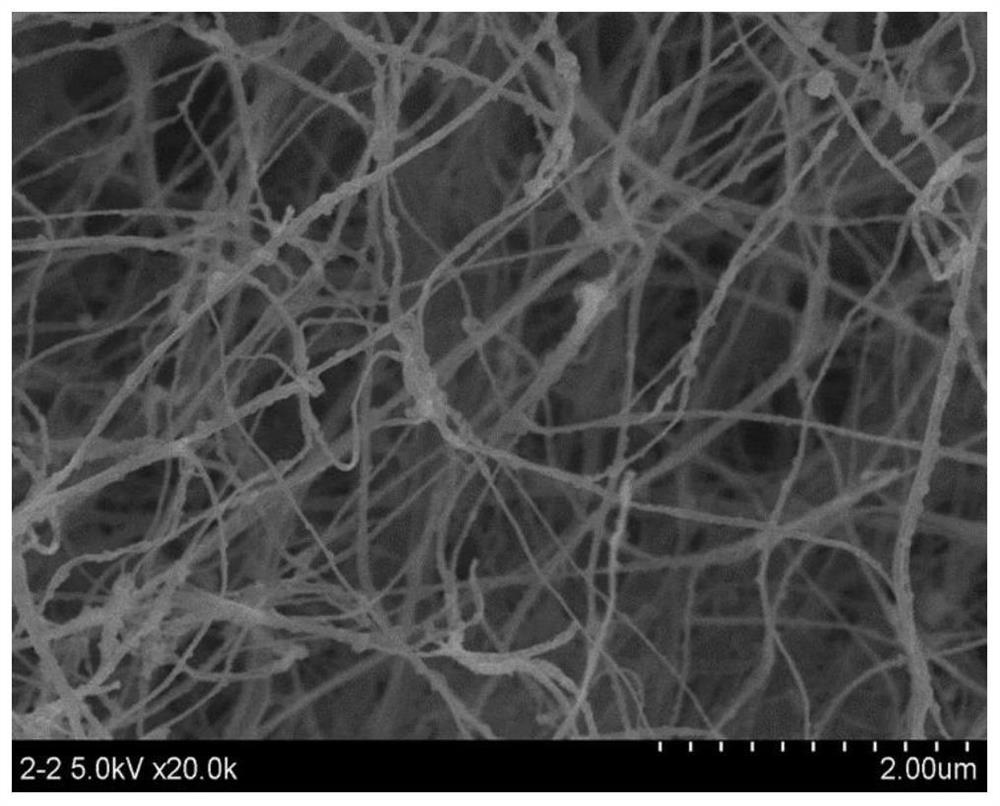

[0054] (1) Through in-situ static culture, the original BNC tube with an inner diameter of 10 mm, an outer diameter of 15 mm and a length of 200 mm (the schematic diagram of the in-situ static culture bioreactor is shown in Figure 10 shown), placed in 1% NaOH solution, 80° C., in a water bath for 4 hours, and then repeatedly replaced to neutral with ultrapure water to obtain a pretreated BNC tube.

[0055] (2) 100 mL of 1% citric acid solution was prepared with ultrapure water, and 1 g of chitosan was dissolved in the above citric acid solution. Place the BNC tube sleeve obtained in step (1) on a silicone tube with an outer diameter of 10mm in the citric acid solution of chitosan, 30°C, 100rpm, shake in a water bath for 12h, then immerse in 1% Na 2 CO 3 The solution was left to stand for 4 hours, then washed, and replaced repeatedly to neutrality with ultrapure water to obtain a bacterial nanocellulose / 1% chitosan BNC / 1% CH composite tube.

[0056] (3) Place the BNC / 1%CH co...

Embodiment 3

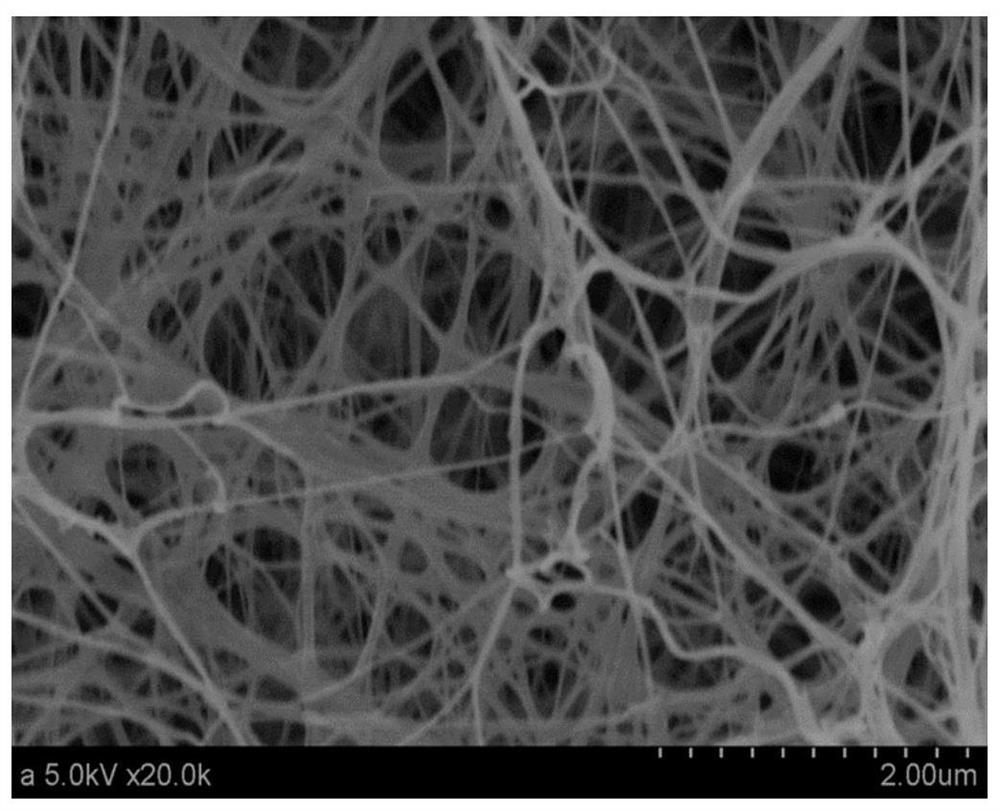

[0059] (1) After the bacterial nanocellulose membrane obtained by in-situ static culture is fully pulverized, the BNC homogenate with a cellulose dry weight content of 0.5% is obtained and poured into a glass rod (3mm in diameter) and a polypropylene tube (with an inner diameter of 8mm, thickness 1mm) in the cavity between the two ends are fixed with rubber stoppers (the schematic diagram of the mold is shown in Figure 11 shown). After repeated freezing and thawing at -20°C and 30°C for 5 times, freeze at -80°C for 4 hours, open the rubber stoppers at both ends of the mold, and freeze-dry to obtain a pretreated BNC tube.

[0060] (2) 100 mL of 1% hydrochloric acid solution was prepared with ultrapure water, and 5 g of chitosan was dissolved in the hydrochloric acid solution. Place the BNC tube sleeve obtained in step (1) on a silicone tube with an outer diameter of 3mm in the hydrochloric acid solution of chitosan, 30°C, 100rpm, shake in a water bath for 12h, then immerse in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com