Microemulsion type water-soluble metal cutting fluid and preparation method thereof

A metal cutting fluid and water-soluble technology, applied in the field of metal product processing, can solve the problems of workpiece corrosion, poor lubricity, polluted working environment, etc., and achieve the effects of strong stability and rust resistance, superior lubricating performance and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

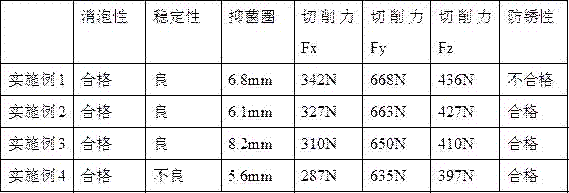

Examples

Embodiment 1

[0031] A microemulsified water-soluble metal cutting fluid, the cutting fluid consists of:

[0032] Base oil A: palm oil: linolenic acid: thiodiacetic acid = 1:1: (1.5), 5wt.%;

[0033] Surfactant B: acetylene glycol surfactant, 2wt.%;

[0034] Stabilizer C: aminobutanol: methyldiethanolamine=1:2, 2wt.%,

[0035] Extreme pressure agent D: vulcanized grease: 0.1wt.%;

[0036] Fungicide E: 2-mercaptopyridine N-oxide sodium salt hydrate, 0.1wt.%;

[0037] Metal antioxidant F: benzotriazole, 0.5wt.%;

[0038] Defoamer H: polydimethylsiloxane, 1wt.%;

[0039] Anti-hardening water agent G: ethylenediaminetetraacetic acid, 0.5wt.%;

[0040] Quaternary ammonium salt precipitant K: dodecyltrimethylammonium bromide, 1wt.%;

[0041] The balance is distilled water, and the stabilizer can react with the base oil to generate alkanolamine carboxylate.

[0042] A preparation method of microemulsion type water-soluble metal cutting fluid, comprising the following steps:

[0043] (1) We...

Embodiment 2

[0046] A microemulsified water-soluble metal cutting fluid, the cutting fluid consists of:

[0047] Base oil A: palm oil: linolenic acid: thiodiacetic acid=1:1:1.5, 23wt.%;

[0048] Surfactant B: acetylene glycol surfactant, 6wt.%;

[0049] Stabilizer C: aminobutanol: methyldiethanolamine=1:2, 14wt.%;

[0050] Extreme pressure agent D: vulcanized grease: 1.5wt.%;

[0051] Fungicide E: 2-mercaptopyridine N-oxide sodium salt hydrate, 2.5wt.%;

[0052] Metal antioxidant F: benzotriazole, 1.7wt.%;

[0053] Defoamer H: polydimethylsiloxane, 1wt.%;

[0054] Anti-hardening water agent G: ethylenediaminetetraacetic acid, 2.3wt.%;

[0055] Quaternary ammonium salt precipitant K: dodecyltrimethylammonium bromide, 3wt.%;

[0056] The balance is distilled water, and the stabilizer can react with the base oil to generate alkanolamine carboxylate.

Embodiment 3

[0058] A microemulsified water-soluble metal cutting fluid, the cutting fluid consists of:

[0059] Base oil A: palm oil: linolenic acid: thiodiacetic acid=1:1:1.5, 30wt.%;

[0060]Surfactant B: acetylene glycol surfactant, 10wt.%;

[0061] Stabilizer C: aminobutanol: methyldiethanolamine=1:2, 15wt.%;

[0062] Extreme pressure agent D: vulcanized grease: 2wt.%;

[0063] Fungicide E: 2-mercaptopyridine N-oxide sodium salt hydrate 4wt.%;

[0064] Metal antioxidant F: benzotriazole, 1wt.%

[0065] Defoamer H: polydimethylsiloxane, 1wt.%;

[0066] Anti-hardening water agent G: ethylenediaminetetraacetic acid, 1.5wt.%;

[0067] Quaternary ammonium salt precipitant K: dodecyltrimethylammonium bromide, 1wt.%;

[0068] The balance is distilled water, and the stabilizer can react with the base oil to generate alkanolamine carboxylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com