Immobilized Catalysts of Silane-Coupled Molecular Sieves and Double Salt Ionic Liquids

A silane coupling, ionic liquid technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry, etc. Insufficient selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

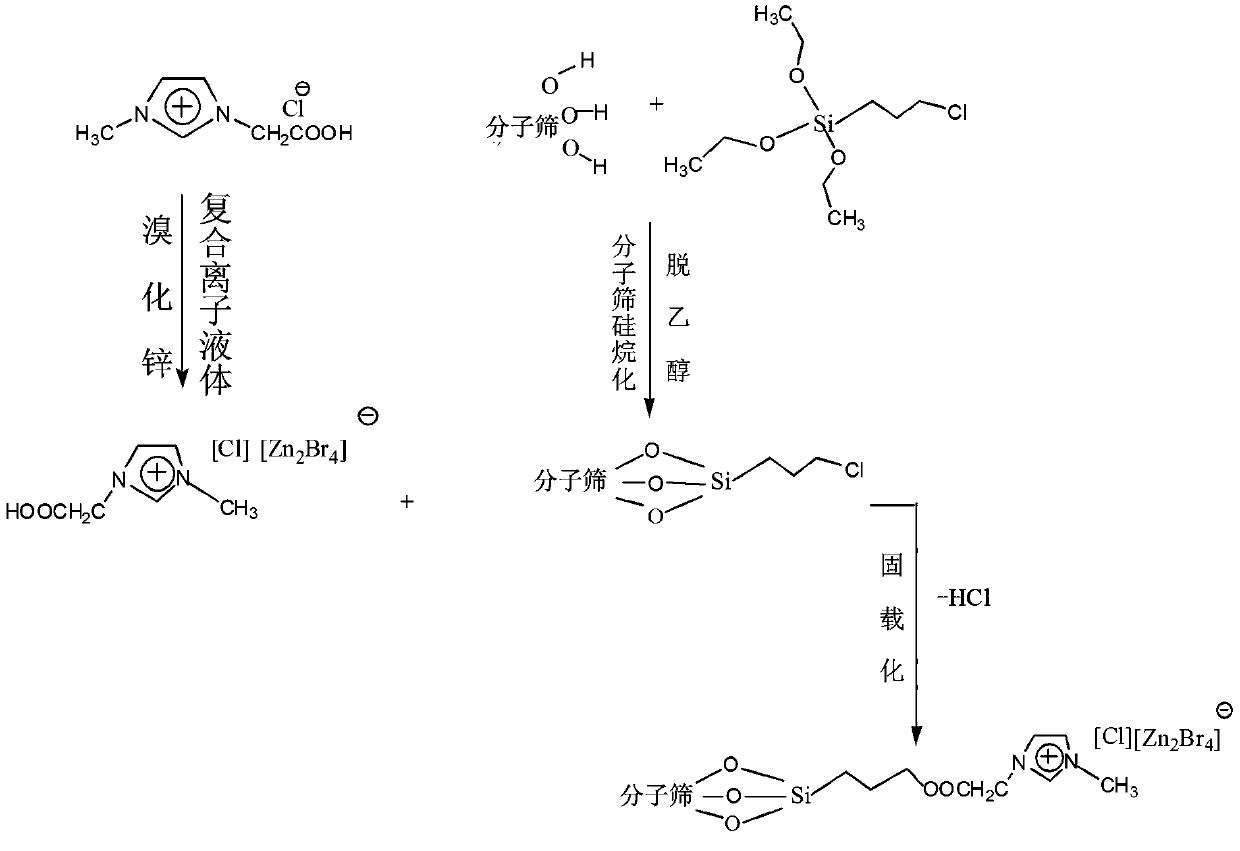

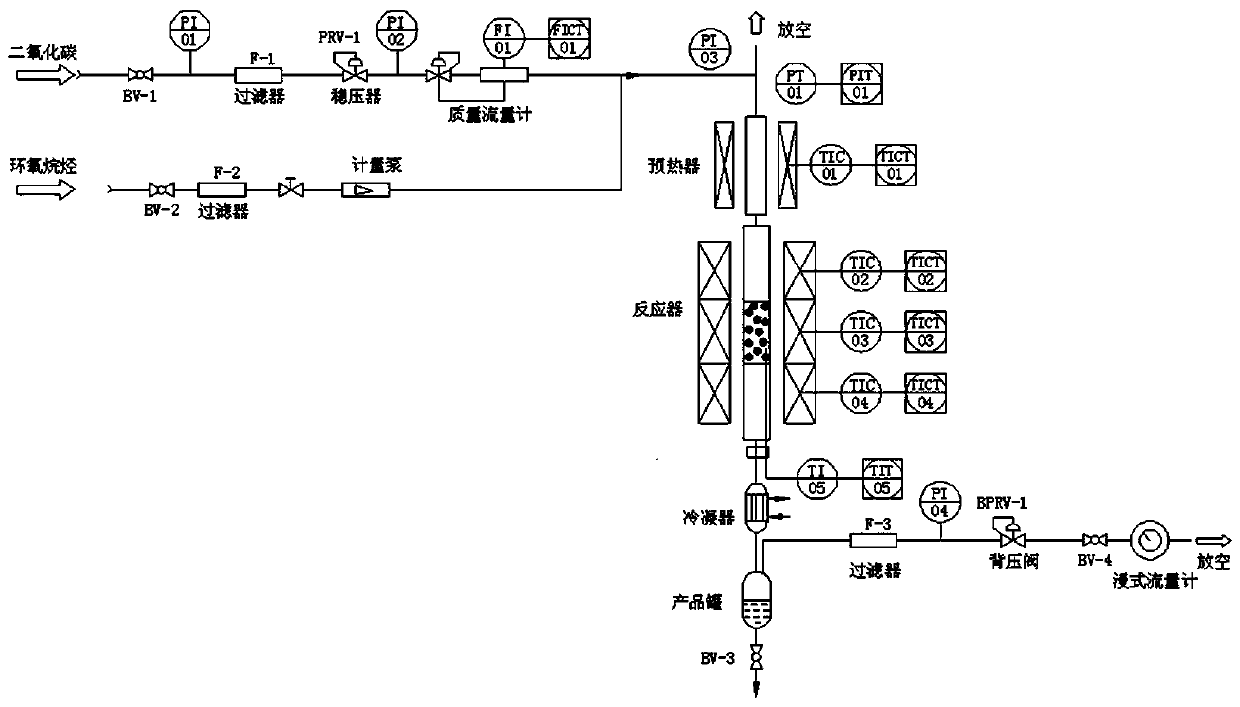

[0034] Preparation method of the present invention carries out according to the following steps:

[0035] 1) First, use methylimidazole or alkylimidazole and halogenated alkyl alcohol / acid to stir at a temperature of 70°C~90°C, and react for 10-24 hours to prepare a functionalized ionic liquid with active groups. Washing, rotary evaporation, and purification for later use;

[0036] 2) Mix the functionalized ionic liquid and Lewis acid with a molar ratio of 1:2 into a three-necked flask, stir and react at 100°C, and continue the reaction for 15 minutes when the system changes from the original solid-liquid two-phase to a homogeneous phase h to obtain the double salt ionic liquid.

[0037] 3) Weigh molecular sieve and silane with a mass ratio of 1:1 and add them into a round bottom flask with a reflux condenser, use toluene as a solvent, react at 110°C for 24 hours, and remove the toluene solvent by rotary evaporation, the sample Dry in a vacuum oven for 12 h to obtain silane mo...

Embodiment 1

[0049] Put 9.63 mL of N-methylimidazole in a 100 mL three-neck flask, add 9.5 g of chloroacetic acid in three batches, and after the chloroacetic acid is completely dissolved, place the reaction in a water bath at 70°C for 10 h to obtain light yellow The liquid was poured into a beaker while it was hot and washed repeatedly with ether three times, placed in a vacuum drying oven at 80°C and -0.09 MPa for 12 h under reduced pressure to obtain 1-carboxyethyl-3-methylimidazolium chloride ionic liquid [CeMIM ] Cl, yield 91%.

[0050] Mix 6.65 g of 1-carboxyethyl-3-methylimidazolium chloride ionic liquid [CeMIM]Cl and 16.96 g of ZnBr2 into a round-bottomed flask with reflux condensation, and stir the reaction at 100 °C until the system consists of When the original solid-liquid two-phase transformation into a homogeneous phase, continue to react for 15 h to obtain the double salt ionic liquid [CeMIM]Cl / (ZnBr2)2.

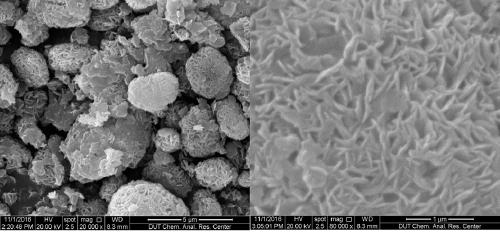

[0051] Mix 5 g molecular sieve MCM-22 and 5 g 3-chloropropyltriethox...

Embodiment 2

[0055] Mix 24 mL of N-methylimidazole and 20 mL of 2-chloroethanol into a round-bottomed flask with a reflux condenser, under nitrogen protection, stir in a water bath at 80°C for 24 h, stop the reaction, and obtain a light yellow liquid Repeated extraction with ether 4 times, placed in a vacuum drying oven at 80°C, -0.09 MPa for 12 h under reduced pressure to obtain 1-(2-hydroxyethyl)-3-methylimidazolium ionic liquid [HeMIM]Cl, The yield was 94%.

[0056] Mix 6.0 g of chlorinated 1-(2-hydroxyethyl)-3-methylimidazolium ionic liquid [HeMIM]Cl and 16.33 g of ZnBr2 into a round-bottomed flask with reflux condensation, and stir the reaction at 100°C , when the system changed from the original solid-liquid two-phase to homogeneous, continue the reaction for 15 h to obtain the double salt ionic liquid [HeMIM]Cl / (ZnBr2)2.

[0057] Mix 5 g molecular sieve MCM-22 and 5 g 3-chloropropyltriethoxysilane (CPTES) into a round bottom flask with a reflux condenser, use toluene as solvent, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com