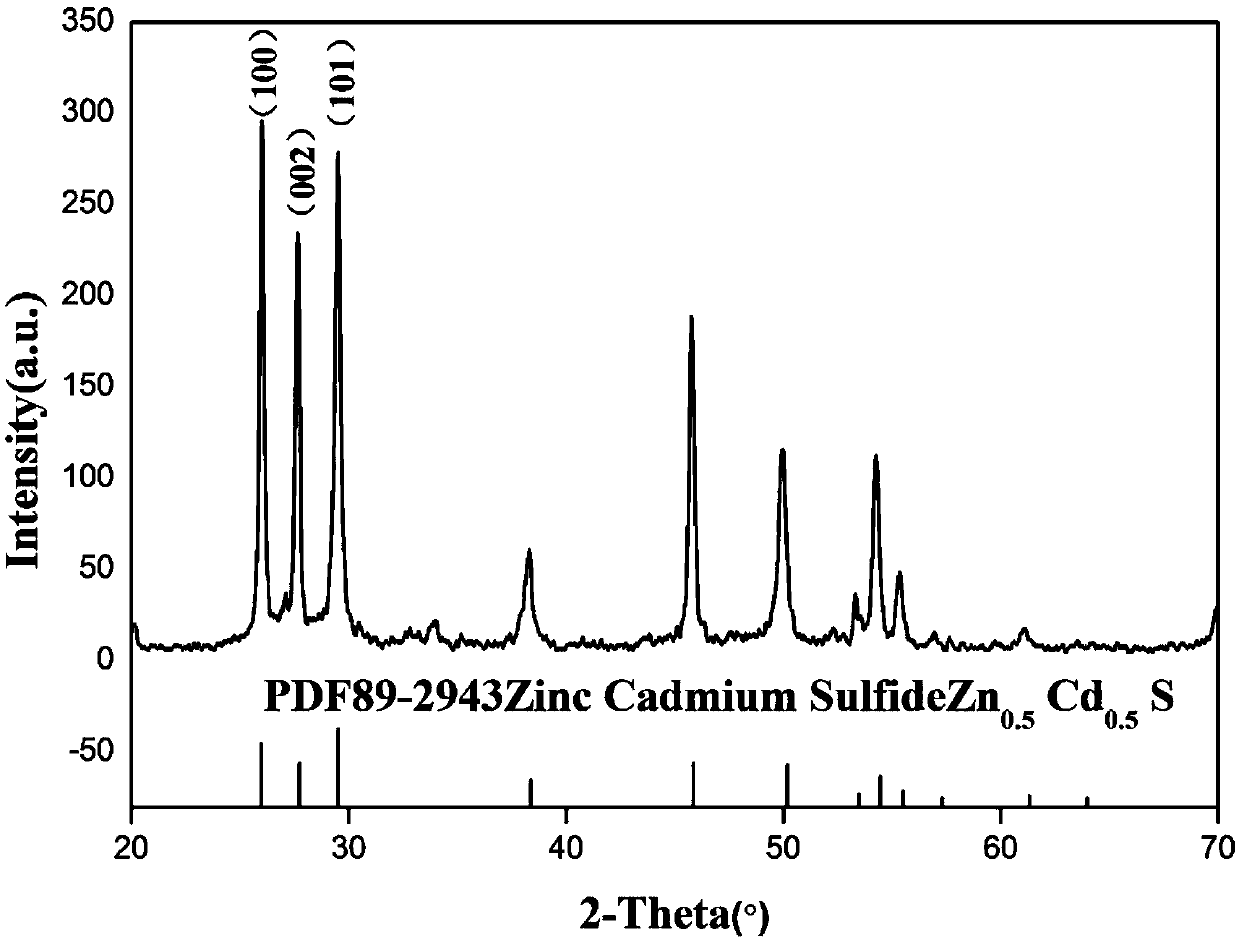

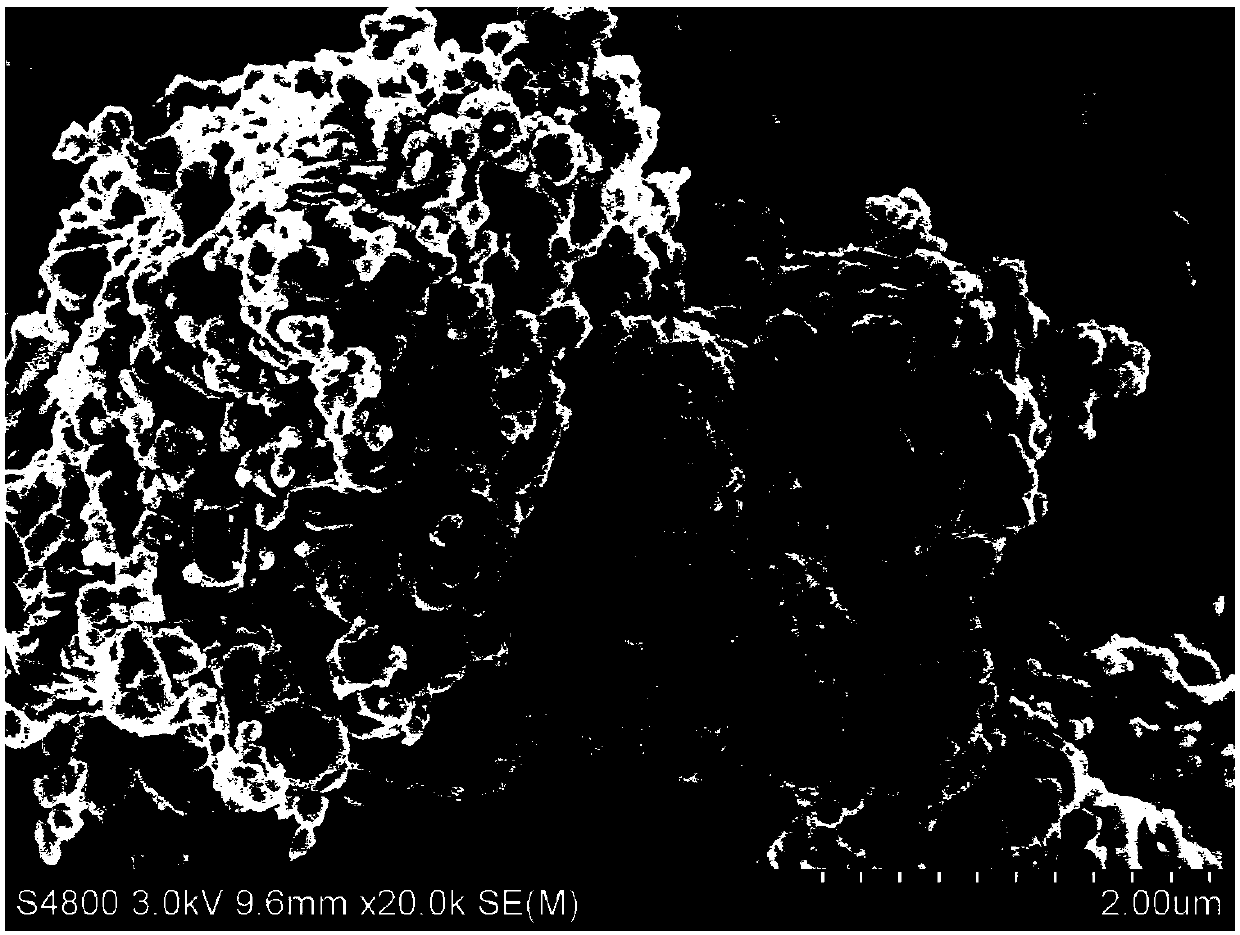

Method for synthesizing zinc, cadmium and sulfur solid solution material by two-step process

A solid solution, zinc-cadmium technology, applied in chemical instruments and methods, cadmium compounds, inorganic chemistry, etc., can solve the problems of high energy and cost requirements for production, products prone to sintering or melting, and difficult to control reaction rates, etc. Achieve the effects of controllable grain growth, short preparation period and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Using zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and cadmium acetate dihydrate (Zn(Cd) 2 2H 2 O) is raw material (n Zn :n Cd =1:1), weigh 0.5mmol respectively, add to DETA and deionized water (V DETA :V H2O =1:9) in 40ml of mixed solution, magnetic stirring was carried out for 15min to form mixed solution A.

[0039] 2) Using thioacetamide as the sulfur source, weigh 1 mmol, add it into the mixed solution A, perform magnetic stirring for 15 minutes, and perform ultrasonication for 5 minutes to form solution B.

[0040] 3) The solution B is added to the polytetrafluoroethylene lining, the filling ratio is controlled at 30%, the reaction temperature is controlled at 140°C, and the reaction time is controlled at 12h.

[0041] 4) After the reaction is completed, centrifuge and wash 3 times with deionized water and ethanol respectively. After vacuum drying at 40°C for 4 hours, Zn was obtained by grinding 0.5 Cd 0.5 S precursor.

[0042] 5) Zn 0.5 Cd 0.5 Put the...

Embodiment 2

[0046] 1) Using zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and cadmium acetate dihydrate (Zn(Cd) 2 2H 2 O) is raw material (n Zn :n Cd =1:1), weigh 0.8mmol respectively, add to DETA and deionized water (V DETA :V H2O =1:9) in 40ml of mixed solution, magnetic stirring was carried out for 15min to form mixed solution A.

[0047] 2) Using thioacetamide as the sulfur source, weigh 1.5 mmol, add it into the mixed solution A, perform magnetic stirring for 15 minutes, and perform ultrasonication for 15 minutes to form solution B.

[0048] 3) The solution B is added into the polytetrafluoroethylene lining, the filling ratio is controlled at 35%, the reaction temperature is controlled at 160°C, and the reaction time is controlled at 18h.

[0049] 4) After the reaction is completed, wash by centrifugation with deionized water and ethanol 4 times respectively. After vacuum drying at 50°C for 3 hours, Zn was obtained by grinding 0.5 Cd 0.5 S precursor.

[0050] 5) Zn 0.5 Cd 0.5...

Embodiment 3

[0054] 1) Using zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and cadmium acetate dihydrate (Zn(Cd) 2 2H 2 O) is raw material (n Zn :n Cd =1:1), weigh 1.0mmol respectively, add to DETA and deionized water (V DETA : V H 2 (0=1:9) mixed solution 40ml, carry out magnetic stirring for 15min to form mixed solution A.

[0055] 2) Use thioacetamide as the sulfur source, weigh 2 mmol, add to the mixed solution A, perform magnetic stirring for 15 minutes, and perform ultrasonication for 30 minutes to form solution B.

[0056] 3) The solution B is added to the polytetrafluoroethylene lining, the filling ratio is controlled at 40%, the reaction temperature is controlled at 180°C, and the reaction time is controlled at 24h.

[0057] 4) After the reaction is completed, centrifuge and wash 6 times with deionized water and ethanol respectively. After vacuum drying at 60°C for 4 hours, Zn was obtained by grinding 0.5 Cd 0.5 S precursor.

[0058] 5) Zn 0.5 Cd 0.5 Put the S precursor in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com