Ferriferous augite based metal ceramic and preparation method thereof

A technology of cermets and pyroxene, applied in the field of Fe/pyroxene cermets and its preparation, can solve problems such as cermet blanks, achieve good thermal stability, expand industrial applications, improve toughness and other mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: A kind of Fe / pyroxene cermet and preparation method thereof

[0044] (1) Taking raw materials according to the chemical composition of CMSA glass-ceramics, wherein iron tailings are 55%, blast furnace slag powder 20%, quartz sand 15%, borax 2%, sodium carbonate 3%, feldspar powder 5%;

[0045] (2) Mixing: batching is carried out according to the above, and put into the mixing machine for mixing;

[0046] (3) Melting material: Put the uniformly mixed raw materials into the crucible, and melt them in a high-temperature resistance furnace at 1450°C for 2 hours; (4) Preparation of water-quenched slag powder: Pour the melted glass liquid into cold water quickly to obtain water The quenched glass particles are then ground in a ball mill to a particle size of 200 mesh to obtain slag glass-ceramic water-quenched slag powder; its composition is shown in Table 2;

[0047] (5) Ingredients: Measure 100 parts of water-quenched slag powder, Fe 2 o 3 15 parts of powde...

Embodiment 2

[0054] Embodiment 2: a kind of Fe / pyroxene cermet and preparation method thereof

[0055] (1) Ingredients: 100 parts of glass-ceramic water-quenched slag powder, Fe 2 o 3 15 parts of powder, 25 parts of ferrosilicon powder containing Fe 75% (weight) are mixed; Wherein the chemical composition of glass-ceramic water-quenching slag is shown in Table 2;

[0056] (2) Mixing: put the mixture into a ball mill tank, and mill it for 1 hour at room temperature to make the powder evenly dispersed;

[0057] (3) Compression molding: the dispersed powder is pressed into a blank by a molding machine, the molding pressure is 50MPa, and isostatic pressing is carried out at a pressure of 180MPa;

[0058] (4) Sintering: Put the formed green body into the atmosphere furnace, feed nitrogen gas at a flow rate of 0.5L / min, raise the temperature to 800°C at a heating rate of 8°C / min, and keep it warm for 3 hours; naturally cool to 200°C and stop the aeration. Nitrogen, continue to cool to room te...

Embodiment 3

[0060] Embodiment 3: a kind of Fe / pyroxene cermet and preparation method thereof

[0061] (1) Ingredients: Measure 100 parts of water-quenched slag powder prepared in Example 1, Fe 2 o 3 10 parts of powder, 30 parts of iron concentrate powder, 50 parts of ferrosilicon powder containing Fe65% (weight) are mixed;

[0062] (2) Mixing: put the mixture into a ball mill tank, and ball mill for 2 hours at room temperature to make the powder evenly dispersed;

[0063] (3) Press molding and sintering: the dispersed powder is put into a graphite mold, first shaped under a pressure of 10MPa, and then put into a spark plasma sintering furnace (SPS) for sintering at a heating rate of 35°C / min Raise the temperature to 800°C, and gradually increase the pressure to 50MPa, keep the temperature and hold the pressure for 20 minutes, and take it out after cooling to room temperature with the furnace.

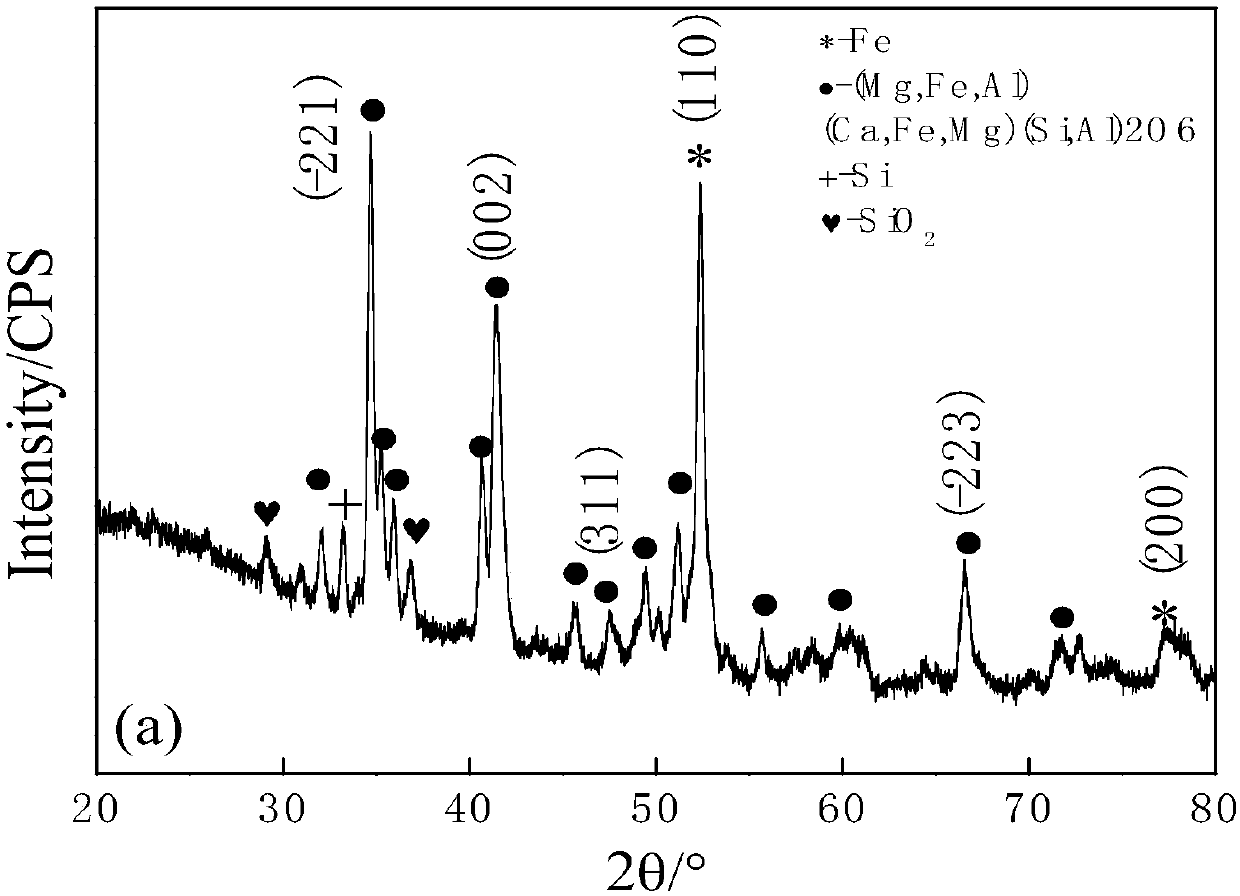

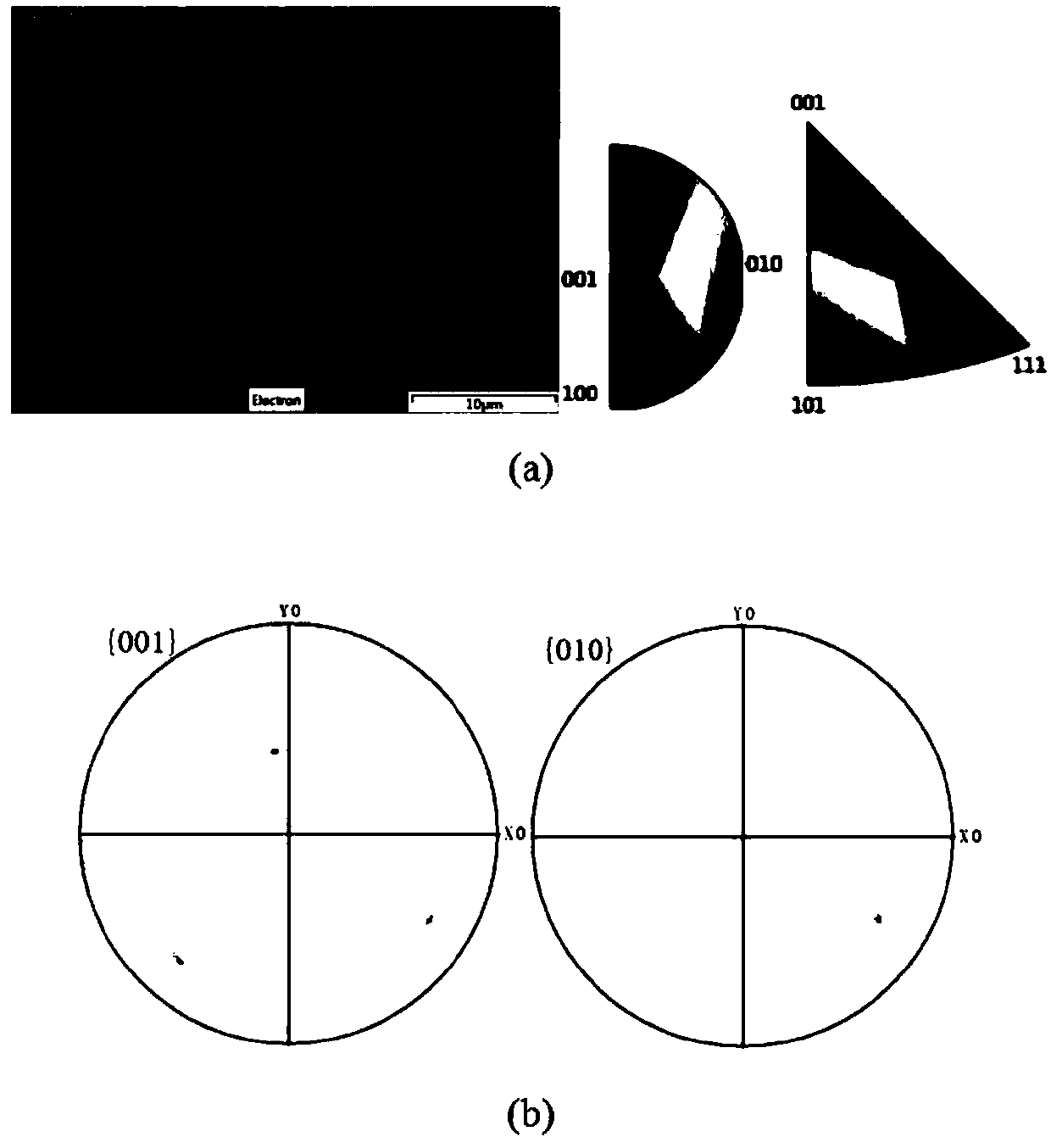

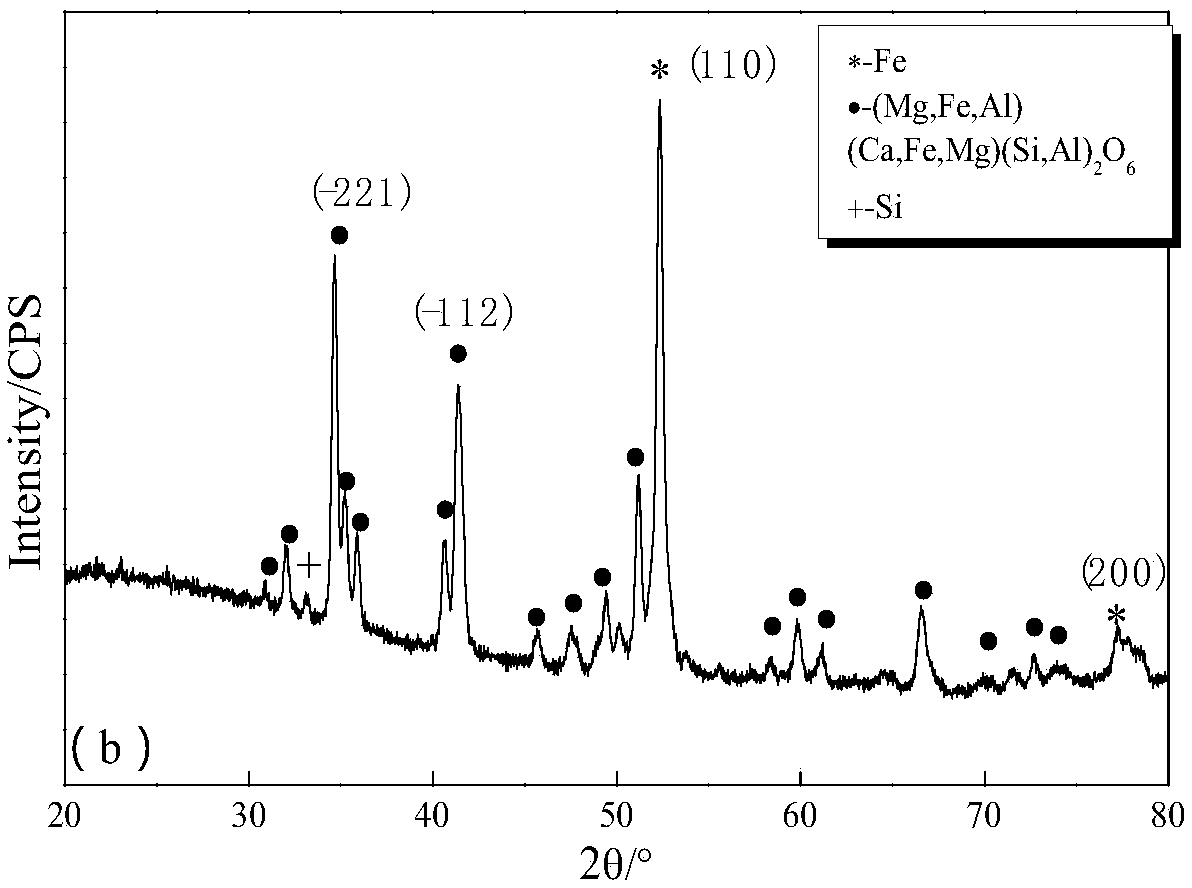

[0064] The density of the sintered samples was measured by the drainage method, and the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com