Propane dehydrogenation Ptx-Sny binary alloy nano-catalyst and preparation method thereof

A nano-catalyst and binary alloy technology, which is applied in the direction of carbon compound catalyst, catalyst, metal/metal oxide/metal hydroxide catalyst, etc., to achieve the effect of improving conversion rate and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a propane dehydrogenation Pt x -Sn y The preparation method of binary alloy nano catalyst:

[0029] Using Pt precursor solution, Sn precursor and hydroxyl donor as reaction raw materials, Pt and Sn metal carbonyl compounds are prepared through carbonylation reaction; then the Pt and Sn metal carbonyl compounds are sequentially loaded, decarbonylated, washed and Drying treatment to obtain the Pt x -Sn y Binary alloy nanocatalysts.

[0030] Specifically include the following steps:

[0031] S101: select a preset solvent, configure a Pt precursor solution, then add a Sn precursor and a hydroxyl donor into the Pt precursor solution, and stir evenly. Wherein, the Pt precursor includes one or more of sodium chloroplatinate, chloroplatinic acid, potassium chloroplatinate, and hexahydroxyplatinic acid bis(ethanolamine); the Sn precursor includes SnCl 4 and / or SnCl 2 The hydroxyl donor includes one or more of sodium citrate, sodium formate, sodium a...

Embodiment 1

[0040] The invention provides a propane dehydrogenation Pt x -Sn y The preparation method of binary alloy nano-catalyst comprises the following steps:

[0041] S101: Add 0.01mol / L sodium chloroplatinate methanol solution to a 100mL three-neck flask, weigh 0.034mmol of SnCl 4 And 1.360mmol of sodium acetate into the three-necked flask. Seal the top of the condenser tube and apply vacuum grease evenly on its lower part, and connect it to the mouth of the middle flask.

[0042] S102: After the system is sealed, after repeated vacuum pumping and nitrogen filling, CO gas is introduced into the three-necked flask under magnetic stirring, the magnetic stirrer speed is adjusted to 900r / min, and the carbonylation reaction is carried out at a temperature of 50°C for 24 hours to obtain Pt-Sn carbonyl compound alcohol solution.

[0043] S103: Add 4g of Al to the dipping bottle 2 o 3 The carrier and the methanol solution were repeatedly vacuumed and filled with nitrogen, and then pla...

Embodiment 2

[0049] This embodiment is set up on the basis of the first embodiment; except step S103, other steps are the same as the first embodiment.

[0050] Specifically, S103: Add 0.2 g of Al to the dipping bottle 2 o 3 The carrier and the methanol solution were repeatedly vacuumed and filled with nitrogen, and then placed in an ultrasonic device for ultrasonic vibration treatment for 1 hour. Then add the Pt obtained by S102 x -Sn y Carbonyl compound alcohol solution, stirring at room temperature for 12h, rotating speed 1000r / min, to obtain the supported carbonyl Pt x -Sn y / Al 2 o 3 Alcoholic solution.

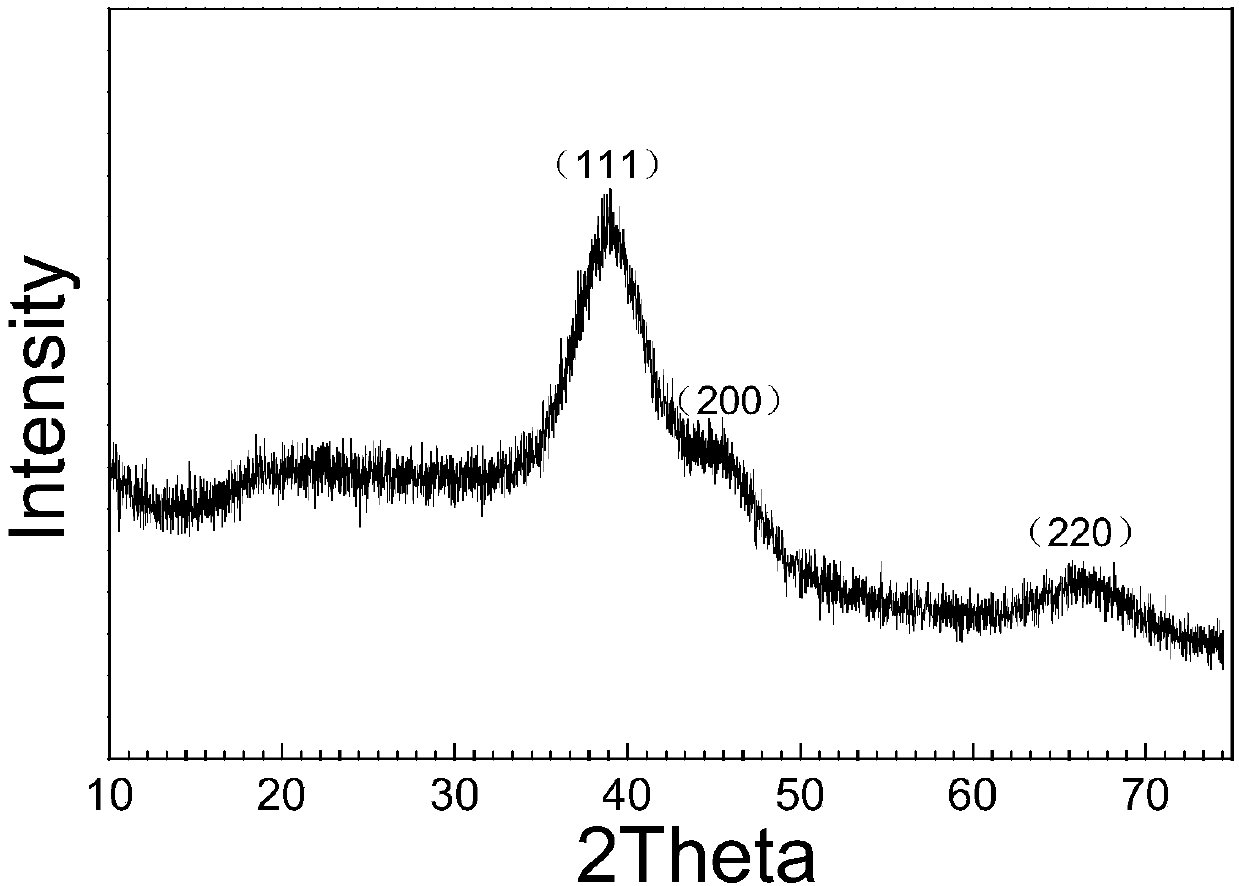

[0051] This embodiment finally prepares Pt with a Pt loading of 10% (mass fraction). 3 Sn / Al 2 o 3 catalyst. The sample obtained in Example two is characterized by X-ray diffraction, and the results are as follows: figure 2 shown. Depend on figure 2It can be seen that the characteristic diffraction angles 2θ of XRD are 38.9, 45.3, and 65.9°, respectively representing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com