One-component moisture-curing polyurethane furniture edge banding adhesive and preparation method thereof

A moisture-curing, polyurethane technology, used in polyurea/polyurethane adhesives, adhesives, polymer adhesive additives, etc., can solve the problems of decreased bonding strength and short storage time, and achieve reduced viscosity and long storage period. , the effect of reducing infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 (comparative example)

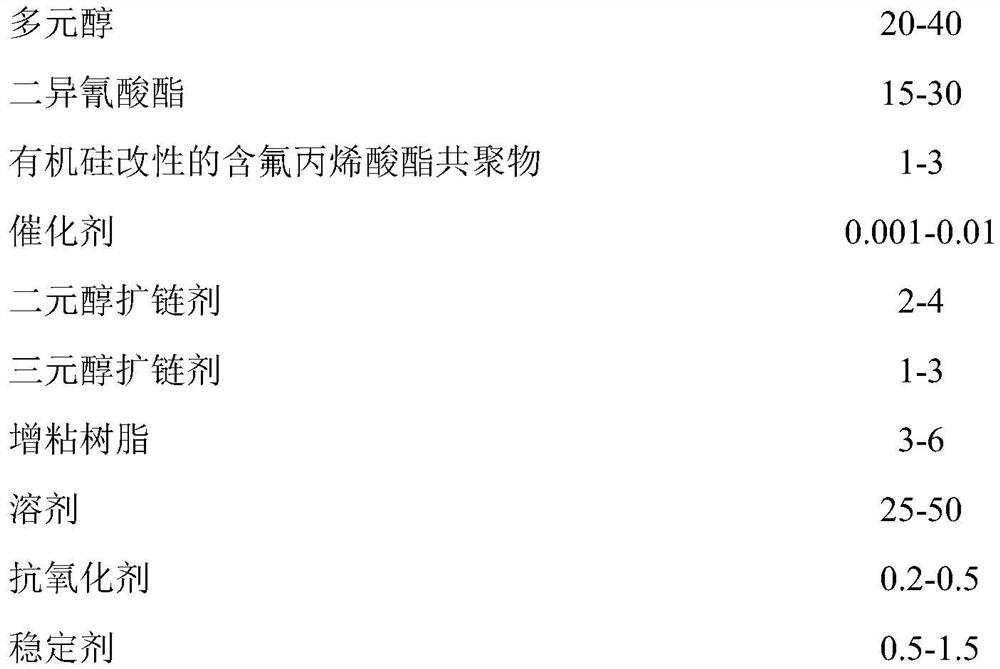

[0048] A preparation method of a single-component moisture-curing polyurethane furniture edge sealant, the composition of the raw material formula is as follows:

[0049]

[0050] According to the above ratio, vacuum dehydrated polyester diol, 2,4-toluene diisocyanate, 2-(2'-hydroxy-3'5'-bis[1,1-dimethylphenyl])- Benzotriazole antioxidants were added to the reaction kettle respectively, and the reaction temperature was controlled at 60-65°C, N 2 Under the atmosphere, the reaction was fully stirred for 30 min. Subsequently, 1.5 g of dibutyltin tin dilaurate was added to the reactor, and the system was heated to 95° C. for 3 hours. Measure the NCO content every half an hour. When the NCO content reaches 18%-19%, cool the system down to 65°C, add 80g of 1,4-butanediol dropwise at a constant speed, and use acetic acid at a mass ratio of 1:2. Dilute with ethyl ester solvent, drop it within 30min, raise the temperature to 75°C for 1h...

Embodiment 2

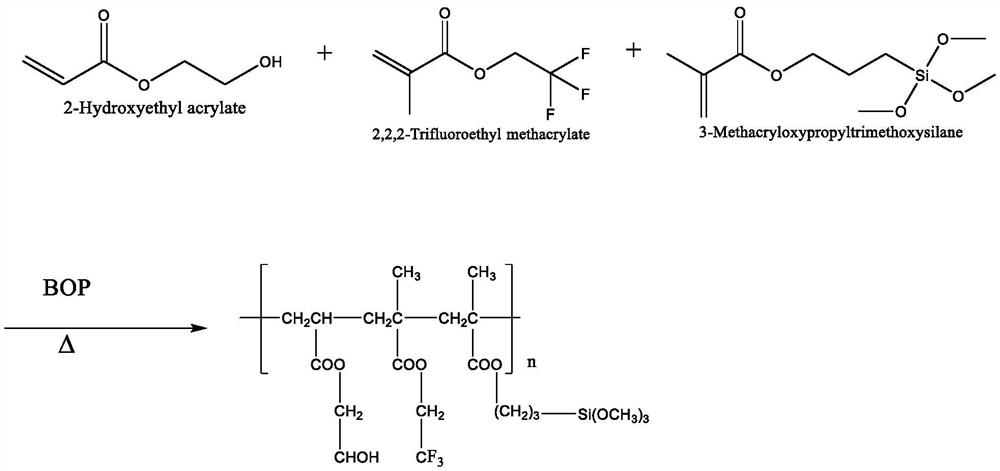

[0052] (1) Synthesis of silicone-modified fluorine-containing acrylate copolymer

[0053] Mix 40g of 2-hydroxyethyl acrylate, 20g of trifluoroethyl methacrylate, 20g of γ-(methacryloyloxy)propyltrimethoxysilane and 0.5g of BOP, heat up to 80-85°C for 3h, After cooling, a silicone-modified fluorine-containing acrylate copolymer solution is obtained.

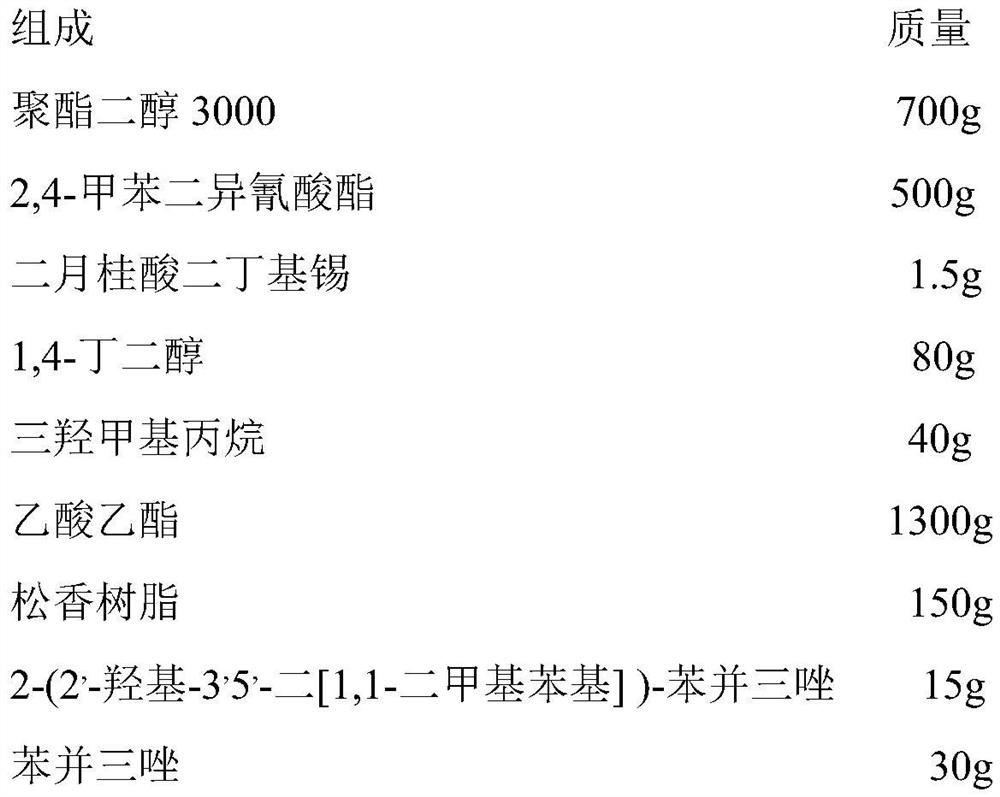

[0054] (2) A preparation method of a single-component moisture-curing polyurethane furniture edge sealant, the composition of the raw material formula is as follows:

[0055]

[0056]

[0057] According to the above ratio, vacuum dehydrated polyester diol, 2,4-toluene diisocyanate, 2-(2'-hydroxy-3'5'-bis[1,1-dimethylphenyl])- Benzotriazole was added to the reaction kettle respectively, and the reaction temperature was controlled at 60-65°C. 2 Under the atmosphere, the reaction was fully stirred for 30 min. Subsequently, 1.5 g of dibutyltin tin dilaurate was added to the reactor, and the system was heated to 95° C. for 3 h...

Embodiment 3

[0059] (1) Synthesis of silicone-modified fluorine-containing acrylate copolymer

[0060] Mix 20g of 2-hydroxyethyl acrylate, 20g of trifluoroethyl methacrylate, 20g of γ-(methacryloyloxy)propyltrimethoxysilane and 0.1g of BOP, heat up to 80-85°C for 2.5h , and after cooling, a silicone-modified fluorine-containing acrylate copolymer solution is obtained.

[0061] (2) A preparation method of a single-component moisture-curing polyurethane furniture edge sealant, the composition of the raw material formula is as follows:

[0062]

[0063]

[0064] According to the above ratio, the vacuum dehydrated polyester diol, 2,4-toluene diisocyanate, bis[β(3-tert-butyl-5-methyl-4-hydroxyphenyl)propionic acid] triethylene glycol The esters were added to the reaction kettle respectively, and the reaction temperature was controlled at 60-65°C, and the N 2 Under the atmosphere, the reaction was fully stirred for 30 min. Subsequently, the catalyst dimorpholine diethyl ether was added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com