A kind of culturing system and culturing method of aerobic anaerobic bacteria using syngas fermentation to produce alcohol

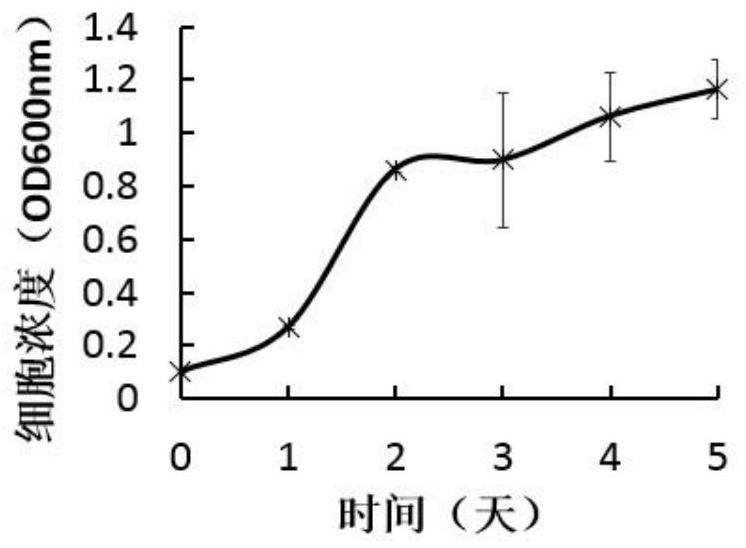

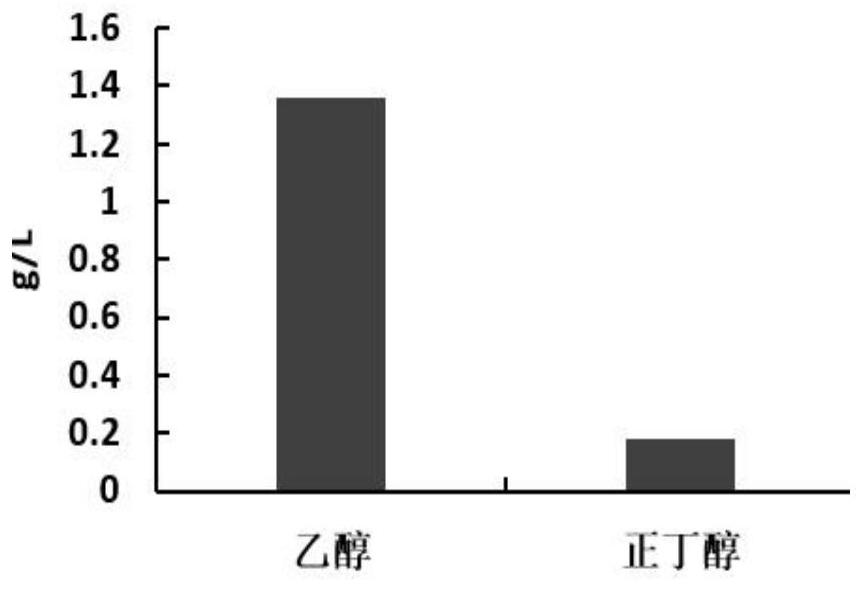

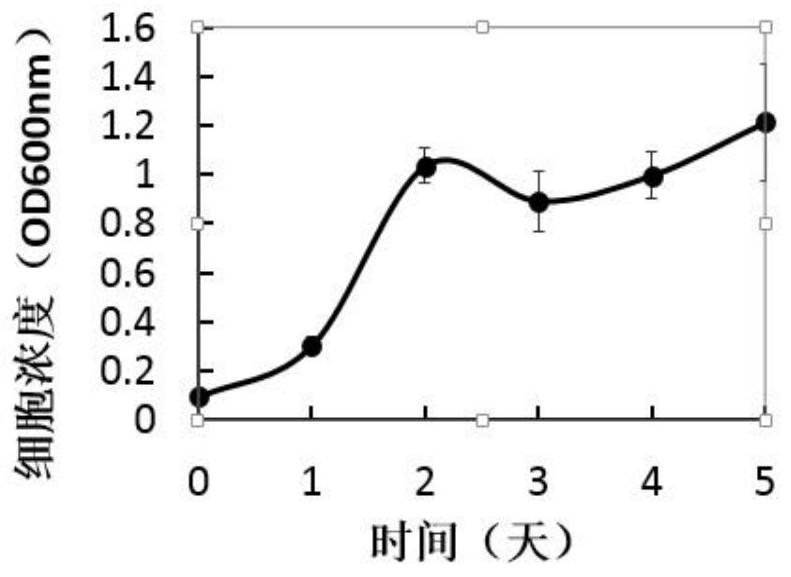

A culture system and synthesis gas technology, applied in the field of microbial fermentation, can solve the problems of weak product synthesis ability and low alcohol production, and achieve the effect of improving the highest concentration and the ability of fermentation to produce alcohol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The macroelement mother liquor of 15ml, the reducing agent of 482.5ml nutrient solution and 2.5ml are formulated into 500ml culture medium, wherein macroelement mother liquor comprises the component of following mass content: 8% sodium chloride, 10% ammonium chloride, 1% chlorine Potassium chloride, 1% potassium dihydrogen phosphate, 2% magnesium sulfate, 0.4% calcium chloride and the rest of the water; the nutrient aqueous solution includes the components of the following quality: the yeast extract of 0.5g, the morpholine of 2.5g Ethansulfonic acid and the water of remainder; water.

[0059]Distribute the prepared culture medium into 100mL serum bottles with a liquid volume of 30mL. Seal the mouth of the bottle with a rubber stopper, fill the serum bottle with 99.999% nitrogen gas at a rate of 2.5 L / min with a nitrogen bottle connected to a needle to remove residual oxygen in the serum bottle, and stop the inflation after the inflation time reaches 5 minutes. Sterili...

Embodiment 2

[0062] The macroelement mother liquor of 10ml, the nutrient aqueous solution of 487.5ml and the reducing agent of 2.5ml are formulated into 500ml culture medium, and wherein macroelement mother liquor comprises the component of following mass content: 8% sodium chloride, 10% ammonium chloride, 1% chlorine Potassium chloride, 1% potassium dihydrogen phosphate, 2% magnesium sulfate, 0.4% calcium chloride and the rest of the water; the nutrient aqueous solution includes the components of the following quality: the yeast extract of 0.5g, the morpholine of 2.5g Ethansulfonic acid and the water of remainder; water.

[0063] Distribute the prepared culture medium into 100mL serum bottles with a liquid volume of 30mL. Seal the mouth of the bottle with a rubber stopper, fill the serum bottle with 99.999% nitrogen gas at a rate of 2.5 L / min with a nitrogen bottle connected to a needle to remove residual oxygen in the serum bottle, and stop the inflation after the inflation time reaches...

Embodiment 3

[0066] The macroelement mother liquor of 15ml, 484ml nutrient aqueous solution and the reductant of 1.0ml are formulated into 500ml culture medium, and wherein macroelement mother liquor comprises the component of following mass content: 8% sodium chloride, 10% ammonium chloride, 1% chloride Potassium, 1% potassium dihydrogen phosphate, 2% magnesium sulfate, 0.4% calcium chloride and the water of remainder; Nutrient aqueous solution comprises the component of following quality: the yeast extract of 0.5g, the morpholine B of 2.5g Sulfonic acid and the water of balance; Reducing agent comprises the component of following mass content: the sodium hydroxide of 0.9%, the L-cysteine hydrochloride of 4%, the sodium sulfide nonahydrate of 4% and the water of balance .

[0067] Distribute the prepared culture medium into 100mL serum bottles with a filling volume of 20mL. Seal the mouth of the bottle with a rubber stopper, fill the serum bottle with 99.999% nitrogen gas at a rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com