Preparation method for porous alumina dealcoholizing agent

A technology of porous alumina and dealcoholization agent, which is applied in the direction of chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., which can solve the problem of decreased catalyst utilization, uneven active components, and uncontrollable loading capacity and other problems, to achieve the effect of no obvious decline in regeneration cycle performance, rich active sites, and obvious synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

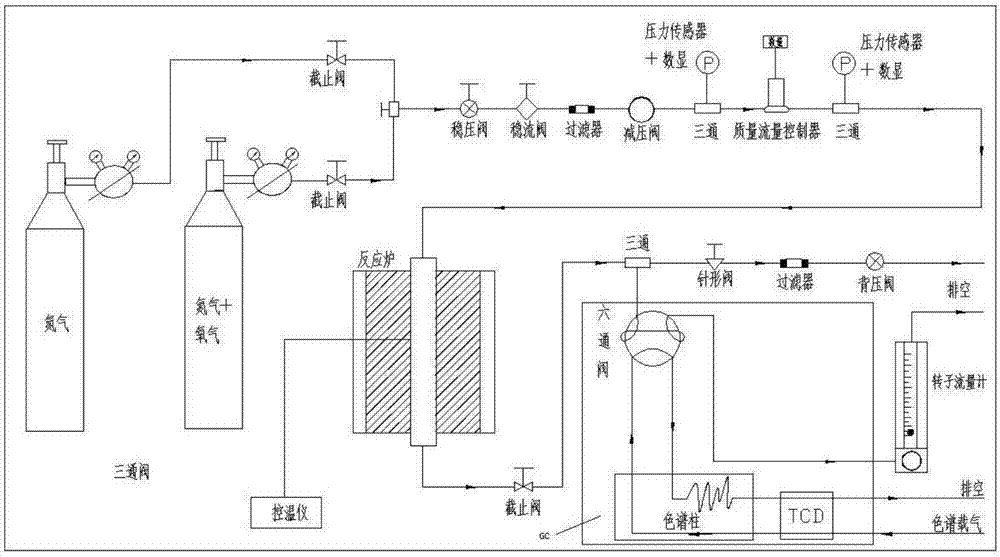

Method used

Image

Examples

Embodiment 1

[0034] 1. Weigh 0.5mol of AlCl 3 .6H 2 O, 0.02mol polyethylene glycol 400, configured as AlCl 3 .6H 2 O mass fraction is 10% solution A, pours in the 500mL there-necked flask, for subsequent use;

[0035] 2. Weigh 0.2 mol of diethylenetriamine (DETA) again, and configure it into lye B with a mass fraction of 10%, for subsequent use;

[0036] 3. Put the three-necked flask containing aluminum chloride hexahydrate solution A in a water bath at 80°C, start stirring at 800r / min, and add lye B to aluminum chloride hexahydrate solution A drop by drop with a constant pressure dropping funnel In the middle, the dropping time is controlled at about 1h, and the control is 7.5<pH<8.5;

[0037] 4. After the dropwise addition is completed, continue to insulate and stir for 1 hour, then stop the reaction to obtain alumina colloid, and age the obtained colloid at the reaction temperature for 18 hours;

[0038] 5. After the aging is completed, add 5% NaHCO 3 , stirring and reacting at 80...

Embodiment 2

[0043] 1. Weigh 0.5mol of AlCl 3 .6H 2 O, 0.02mol polyethylene glycol 400, configured as AlCl 3 .6H 2 O mass fraction is 10% solution A, pours in the 500mL there-necked flask, for subsequent use;

[0044] 2. Weigh again 0.2mol monoethanolamine (MEA), and configure it into lye B with a mass fraction of 10%, and set aside;

[0045] 3. Put the three-necked flask containing aluminum chloride hexahydrate solution A in a water bath at 80°C, start stirring at 800r / min, and add lye B to aluminum chloride hexahydrate solution A drop by drop with a constant pressure dropping funnel In the middle, the dropping time is controlled at about 1h, and the control is 7.5<pH<8.5;

[0046] 4. After the dropwise addition is completed, continue to insulate and stir for 1 hour, then stop the reaction to obtain alumina colloid, and age the obtained colloid at the reaction temperature for 18 hours;

[0047] 5. After the aging is completed, add 5% NaHCO 3 , stirring and reacting at 800r / min for 1...

Embodiment 3

[0052] 1. Weigh 0.5mol of AlCl 3 .6H 2 O, 0.02mol polyethylene glycol 400, configured as AlCl 3 .6H 2 O mass fraction is 10% solution A, pours in the 500mL there-necked flask, for subsequent use;

[0053] 2. Weigh 0.2mol triethanolamine (TEOA) again, and configure it into lye B with a mass fraction of 10%, for subsequent use;

[0054] 3. Put the three-necked flask containing aluminum chloride hexahydrate solution A in a water bath at 80°C, start stirring at 800r / min, and add lye B to aluminum chloride hexahydrate solution A drop by drop with a constant pressure dropping funnel In the middle, the dropping time is controlled at about 1h, and the control is 7.5<pH<8.5;

[0055] 4. After the dropwise addition is completed, continue to insulate and stir for 1 hour, then stop the reaction to obtain alumina colloid, and age the obtained colloid at the reaction temperature for 18 hours;

[0056] 5. After the aging is completed, add 5% NaHCO 3 , stirring and reacting at 800r / min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com