Hydrated alumina composition and molded body containing moy molecular sieve, preparation method and application, catalyst and preparation method

A hydrated alumina and molding method technology, which is applied in the field of alumina molding technology, can solve problems such as transfer difficulties, secondary dust pollution, and molding interference, and achieve the goals of simplifying the process flow, improving the working environment, and reducing operating energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

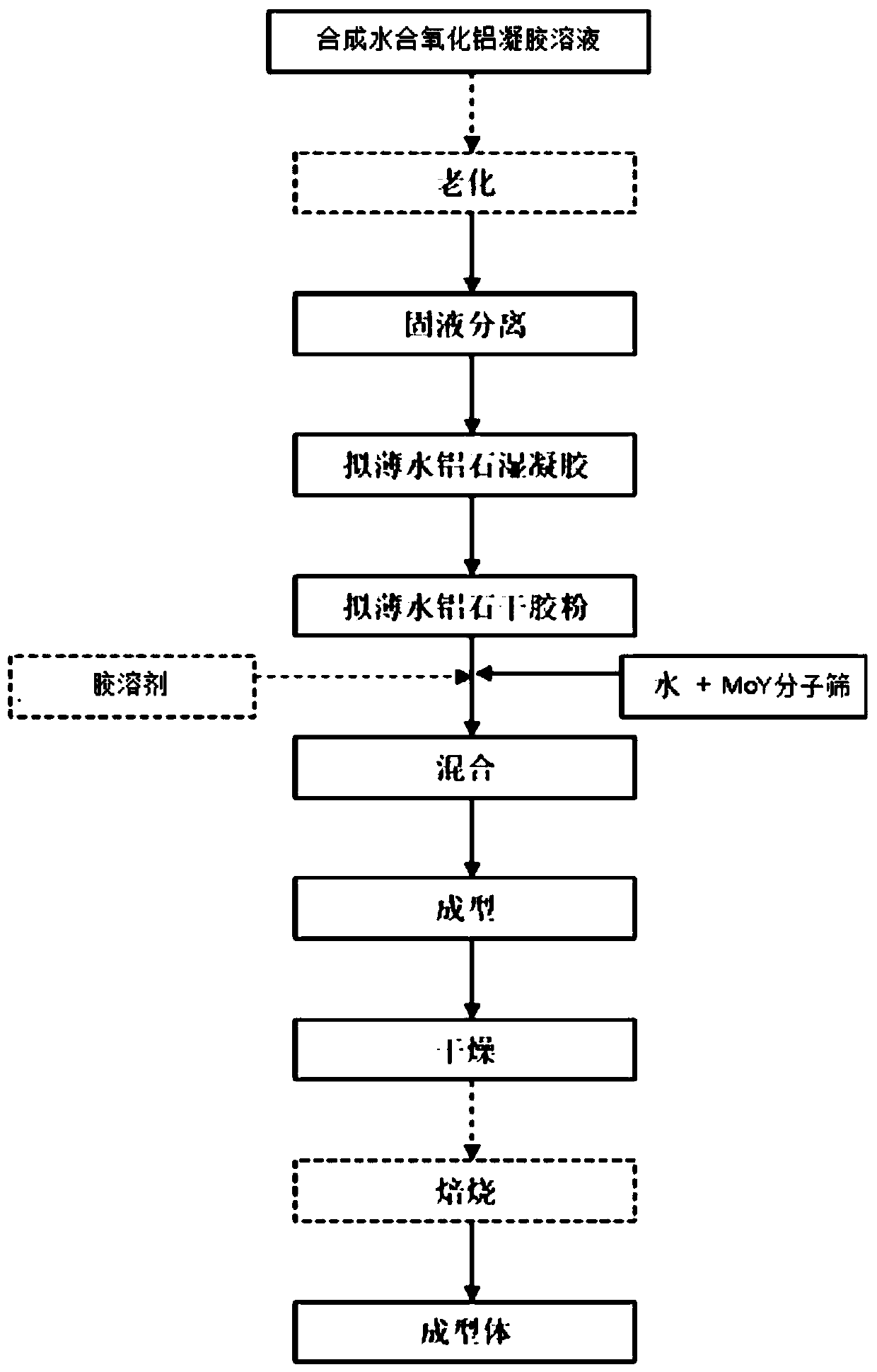

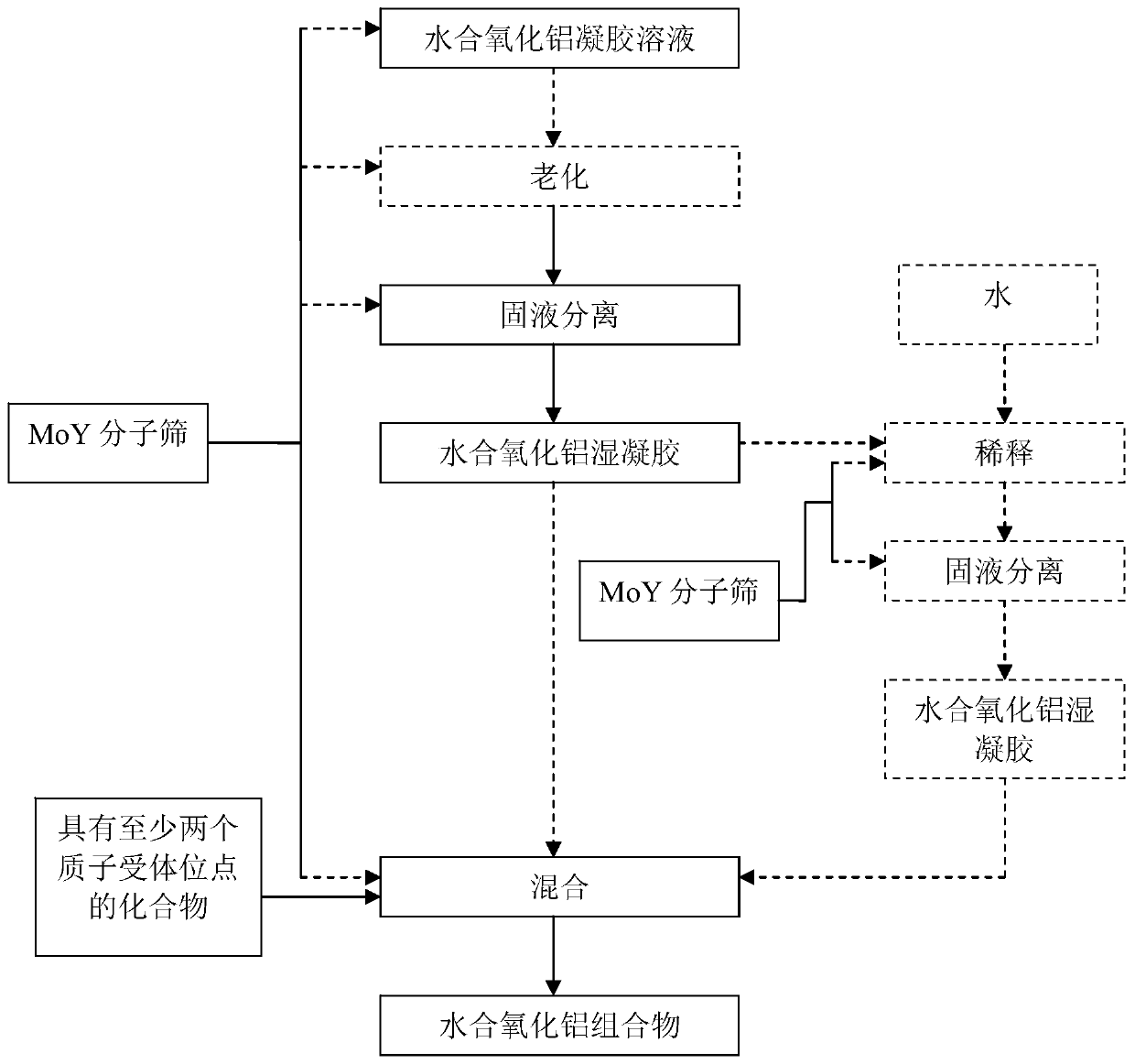

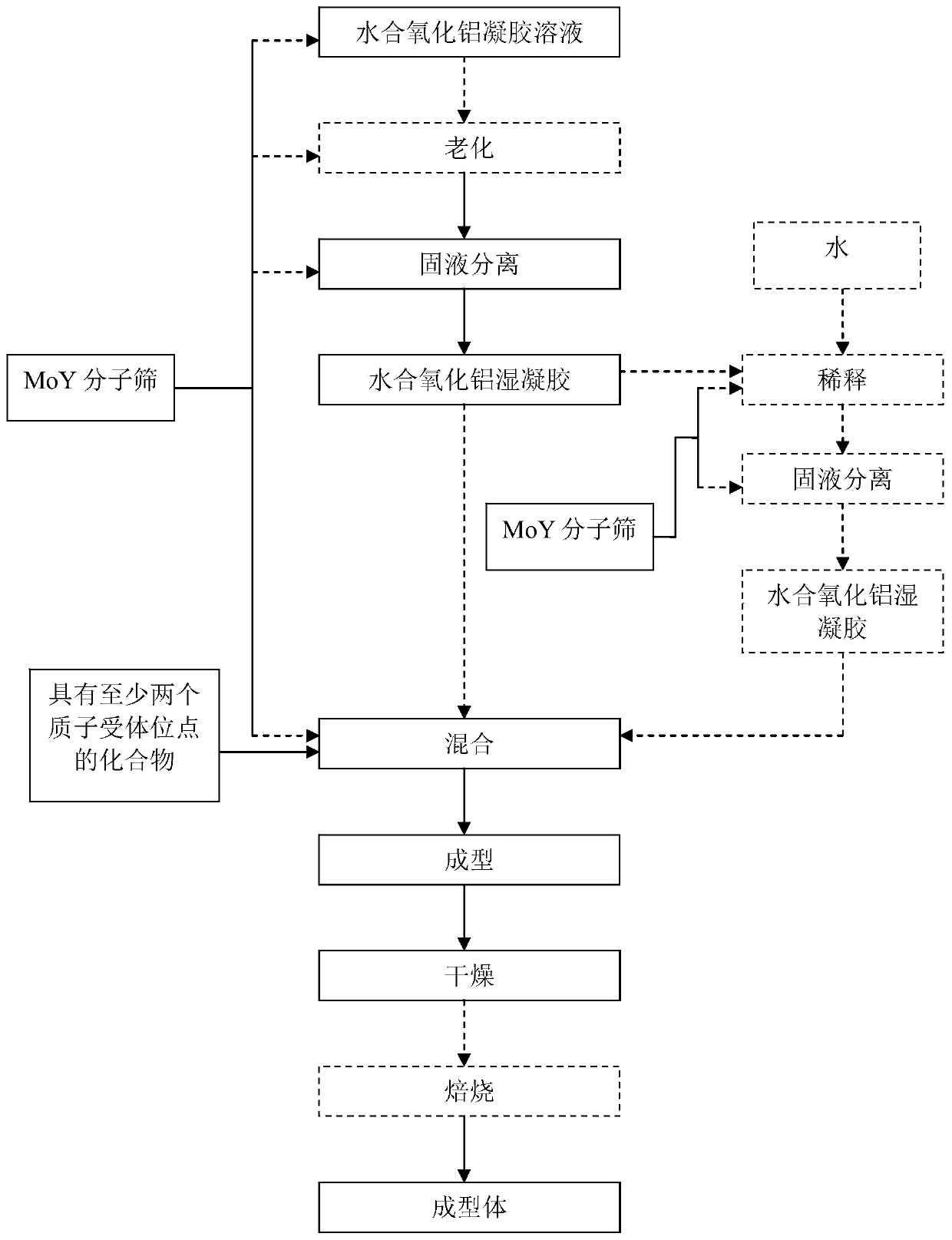

Method used

Image

Examples

preparation example Construction

[0121] According to the preparation method of the hydrated alumina composition of the present invention, the raw material mixture contains hydrated alumina wet gel, MoY molecular sieve and a compound having at least two proton acceptor sites. The compound having at least two proton acceptor sites and its type, as well as the MoY molecular sieve and its type have been described in detail above, and will not be repeated here.

[0122] The hydrated alumina wet gel can be synthesized by conventional methods, such as one or more of precipitation method (including acid method and alkali method), hydrolysis method, seed separation method and rapid dehydration method. Generally, it is obtained by optionally aging the hydrated alumina gel solution, followed by washing and solid-liquid separation.

[0123] The precipitation method includes acid method and alkali method. The acid method is to carry out precipitation reaction of aluminum salt with basic compound. The alkali method is to...

Embodiment 1

[0265] The alumina hydrate wet gel used in this example is a quasi-alumina hydrogel solution prepared by the acid method (sodium metaaluminate-aluminum sulfate method, obtained from Sinopec Changling Branch) after washing and filtering. The wet filter cake of boehmite (the wet filter cake is coded as SLB-1), after measurement, the i value of the wet filter cake is 78.2%.

[0266] The MoY molecular sieve used in the present embodiment adopts following method to make:

[0267] Get 200.0 grams of USY molecular sieves (the product of Sinopec Catalyst Changling Branch Company, unit cell constant is The dry basis is 0.75, the sodium oxide content is less than 0.08% by weight) and 6.3 grams of molybdenum trioxide are ground in a mortar and mixed uniformly. Then, the ground material is placed in the constant temperature zone of the tube furnace, and the mixed gas of hydrogen and water vapor is continuously introduced into the tube furnace, and roasted at 450 ° C for 4 hours, wherein...

Embodiment 2

[0278] (1) Mix 5 kg of wet filter cake numbered SLBY-1 with 500 g of deionized water for beating for 1 minute, then send the resulting slurry into a plate and frame filter press, adjust the pressure of the plate and frame to 0.7 MPa and maintain After 15 minutes, a wet filter cake (coded as LBY-1) was obtained. It has been determined that the i value of the wet filter cake numbered LBY-1 is 68%.

[0279] (2) 300g of wet filter cake numbered LBY-1 was placed in a beaker, and 4.3g of hydroxyethyl methylcellulose (purchased from Shanghai Huiguang Fine Chemical Co., Ltd., the same below) and 1.7g of scallop powder ( The content of galactomannan is 85% by weight (purchased from Beijing Chemical Reagent Company). After stirring for 10 minutes with a mechanical stirrer, the hydrated alumina composition of the present invention is obtained, and its properties are listed in Table 1.

[0280] (3) Extrude the hydrated alumina composition prepared in step (2) on an F-26 twin-screw extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com