Preparation method of medical titanium alloy surface bio-piezoelectric composite coating

A piezoelectric composite and titanium alloy technology, which is applied in the field of surface modification of biomedical materials, can solve the problems of poor binding force between bioactive coatings and substrates, low surface bioactivity, etc., to achieve good combination, good adhesion and value-added, The effect of accelerating bone repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

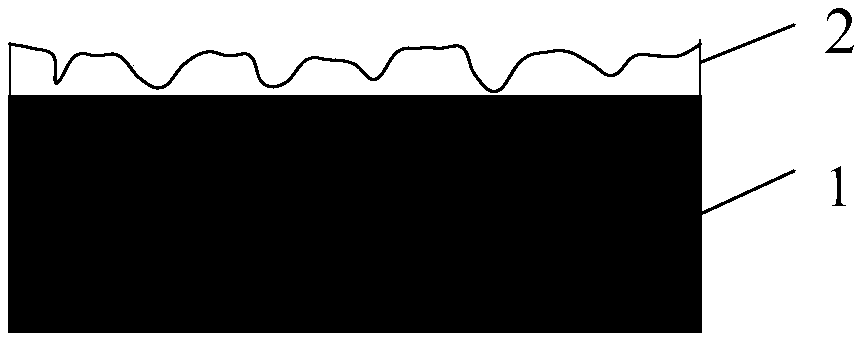

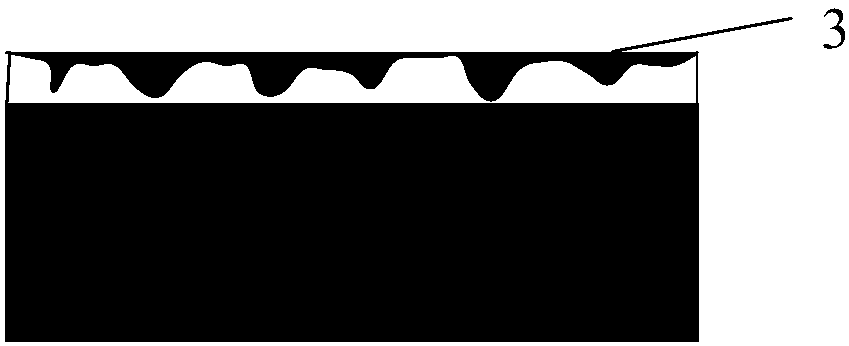

Method used

Image

Examples

Embodiment 1

[0050] Place the pretreated titanium matrix sample in a stainless steel tank containing electrolyte, use the titanium sample as the anode, and the stainless steel tank as the cathode, adopt pulsed DC voltage, the voltage is 200V, the pulse frequency is 700Hz, and the duty cycle is 10 %, the oxidation time is 4min, and the electrolyte temperature is 60°C. The electrolyte is composed of deionized water as the solvent, disodium edetate with a concentration of 0.05mol / L as the solute, calcium acetate with a concentration of 0.01mol / L, and sodium dihydrogen phosphate with a concentration of 0.05mol / L. become;

[0051] Add 50% of the total volume of the reaction kettle into the reaction kettle with a concentration of 0.1mol / L barium hydroxide aqueous solution, place the titanium sample after the micro-arc oxidation treatment in the hydrothermal reaction kettle, and then at a temperature of 140°C, Keep warm for 6 hours;

[0052] The sample processed in the above steps is subjected ...

Embodiment 2

[0055] Place the pretreated titanium matrix sample in a stainless steel tank containing electrolyte, use the titanium sample as the anode, and the stainless steel tank as the cathode, adopt pulsed DC voltage, the voltage is 500V, the pulse frequency is 300Hz, and the duty cycle is 20 %, the oxidation time is 8min, and the electrolyte temperature is 60°C. The electrolyte is composed of deionized water as the solvent, disodium edetate with a concentration of 0.1mol / L as the solute, calcium acetate with a concentration of 0.1mol / L, and sodium dihydrogen phosphate with a concentration of 0.07mol / L. become;

[0056] Add 70% of the total volume of the reaction kettle into the reaction kettle with a concentration of 0.2mol / L barium hydroxide aqueous solution, place the titanium sample after the micro-arc oxidation treatment in the hydrothermal reaction kettle, and then at a temperature of 180°C, Keep warm for 8 hours;

[0057] The sample processed by the above steps is subjected to...

Embodiment 3

[0060] Place the pretreated titanium matrix sample in a stainless steel tank containing electrolyte, use the titanium sample as the anode, and the stainless steel tank as the cathode, adopt pulsed DC voltage, the voltage is 400V, the pulse frequency is 500Hz, and the duty cycle is 30 %, the oxidation time is 10min, and the electrolyte temperature is 60°C. The electrolyte is composed of deionized water as the solvent, disodium edetate with a concentration of 0.2mol / L as the solute, calcium acetate with a concentration of 0.15mol / L, and sodium dihydrogen phosphate with a concentration of 0.3mol / L. become;

[0061] Add 0.3 mol / L barium hydroxide aqueous solution with a concentration of 0.3 mol / L to the reaction kettle, place the titanium sample after the micro-arc oxidation treatment in the hydrothermal reaction kettle, and then at a temperature of 200 ° C, Keep warm for 10 hours;

[0062] The sample processed by the above steps is subjected to polarization treatment in air med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com