Heat sink material with high thermal matching performance for semiconductor lighting

A heat sink material and semiconductor technology, applied in the field of heat sink materials, can solve problems such as insufficient thermal matching performance of heat sink materials, and achieve the effects of good mechanical properties, good thermal matching effect, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

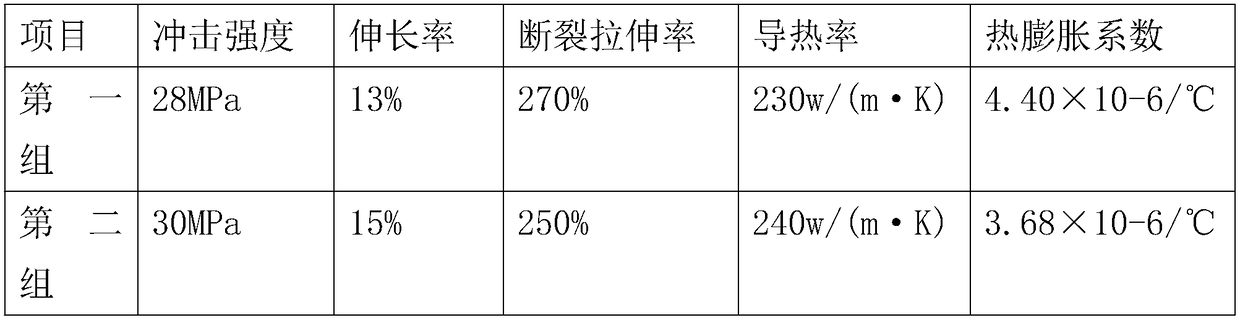

Examples

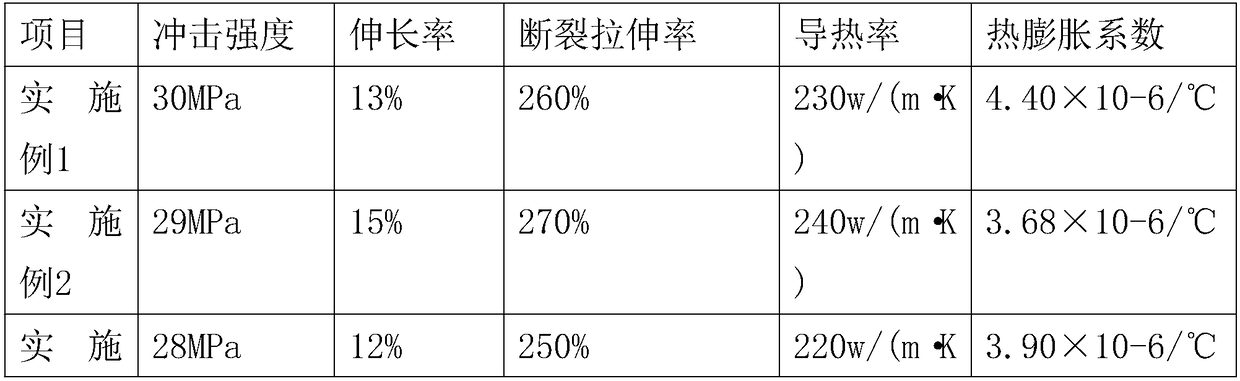

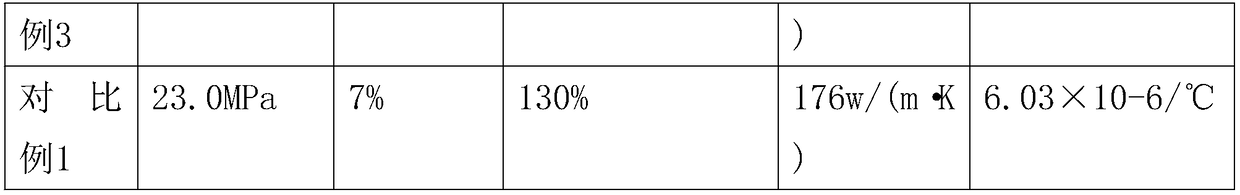

Embodiment 1

[0028] A heat sink material with high thermal matching performance for semiconductor lighting, comprising the following components in parts by mass: 30 parts of graphene, 4 parts of boron oxide, 3 parts of corundum powder, 2 parts of nickel conductive glue, 0.5 parts of barium titanate, 3 parts of sodium chloride, 4 parts of citric acid, 10 parts of chromic anhydride, 10 parts of lamp powder, 5 parts of polyurethane, 2 parts of calcium oxide, 2 parts of diatomaceous earth, 2 parts of hydroxyapatite, 4 parts of zirconia sol, 3 parts of rare earth, 9 parts of grape seed extract, 3 parts of dimethyl itaconate, 5 parts of binder, 1 part of coupling agent, 1 part of compatibilizer, 0.8 part of antioxidant, 0.5 part of stabilizer.

[0029] Among them, the diatomite is modified before use. During the treatment, 10 parts by mass of diatomite and 2 parts by mass of glycerin are mixed and stirred, then 0.5 parts by mass of citric acid is added, and stirred at 55°C for 3 Minutes, the sti...

Embodiment 2

[0041] A heat sink material with high thermal matching performance for semiconductor lighting, comprising the following components in parts by mass: 35 parts of graphene, 6 parts of boron oxide, 5 parts of corundum powder, 5 parts of nickel conductive glue, 1.5 parts of barium titanate, 4.5 parts of sodium chloride, 5 parts of citric acid, 12 parts of chromic anhydride, 15 parts of lamp powder, 8 parts of polyurethane, 3 parts of calcium oxide, 2 parts of diatomaceous earth, 3 parts of hydroxyapatite, 4 parts of zirconia sol, 4 parts of rare earth, 11 parts of grape seed extract, 4 parts of dimethyl itaconate, 8 parts of binder, 2 parts of coupling agent, 1 part of compatibilizer, 1.2 parts of antioxidant, and 1 part of stabilizer.

[0042] Among them, the diatomite is modified before use. During the treatment, 10 parts by mass of diatomite and 2 parts by mass of glycerin are mixed and stirred, then 0.5 parts by mass of citric acid is added, and stirred at 55°C for 5 Minutes, ...

Embodiment 3

[0054] A heat sink material with high thermal matching performance for semiconductor lighting, comprising the following components in parts by mass: 40 parts of graphene, 8 parts of boron oxide, 6 parts of corundum powder, 8 parts of nickel conductive glue, 3 parts of barium titanate, 5 parts of sodium chloride, 6 parts of citric acid, 15 parts of chromic anhydride, 20 parts of lamp powder, 10 parts of polyurethane, 4 parts of calcium oxide, 4 parts of diatomaceous earth, 3 parts of hydroxyapatite, 6 parts of zirconia sol, 5 parts of rare earth, 13 parts of grape seed extract, 5 parts of dimethyl itaconate, 12 parts of binder, 2 parts of coupling agent, 2 parts of compatibilizer, 1.4 parts of antioxidant, 2 parts of stabilizer.

[0055] Among them, the diatomite is modified before use. During the treatment, 10 parts by mass of diatomite and 2 parts by mass of glycerin are mixed and stirred, then 0.5 parts by mass of citric acid is added, and stirred at 55°C for 8 Minutes, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com