Patents

Literature

41 results about "Dimethylitaconate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

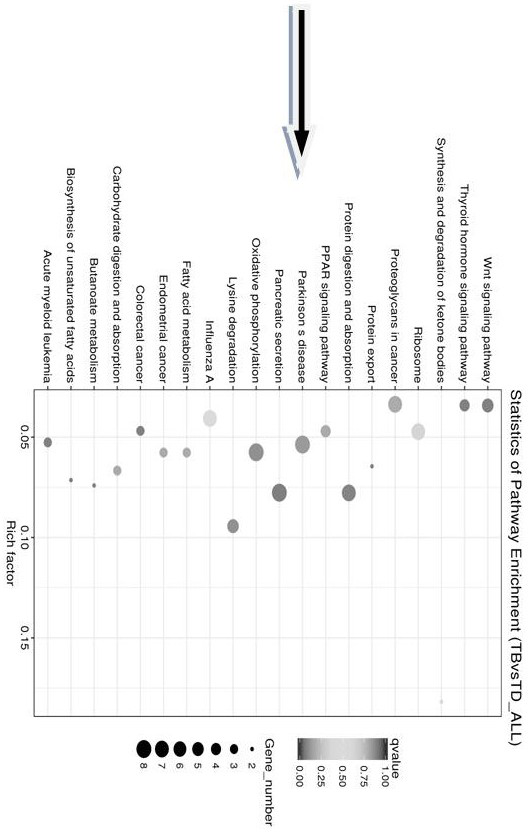

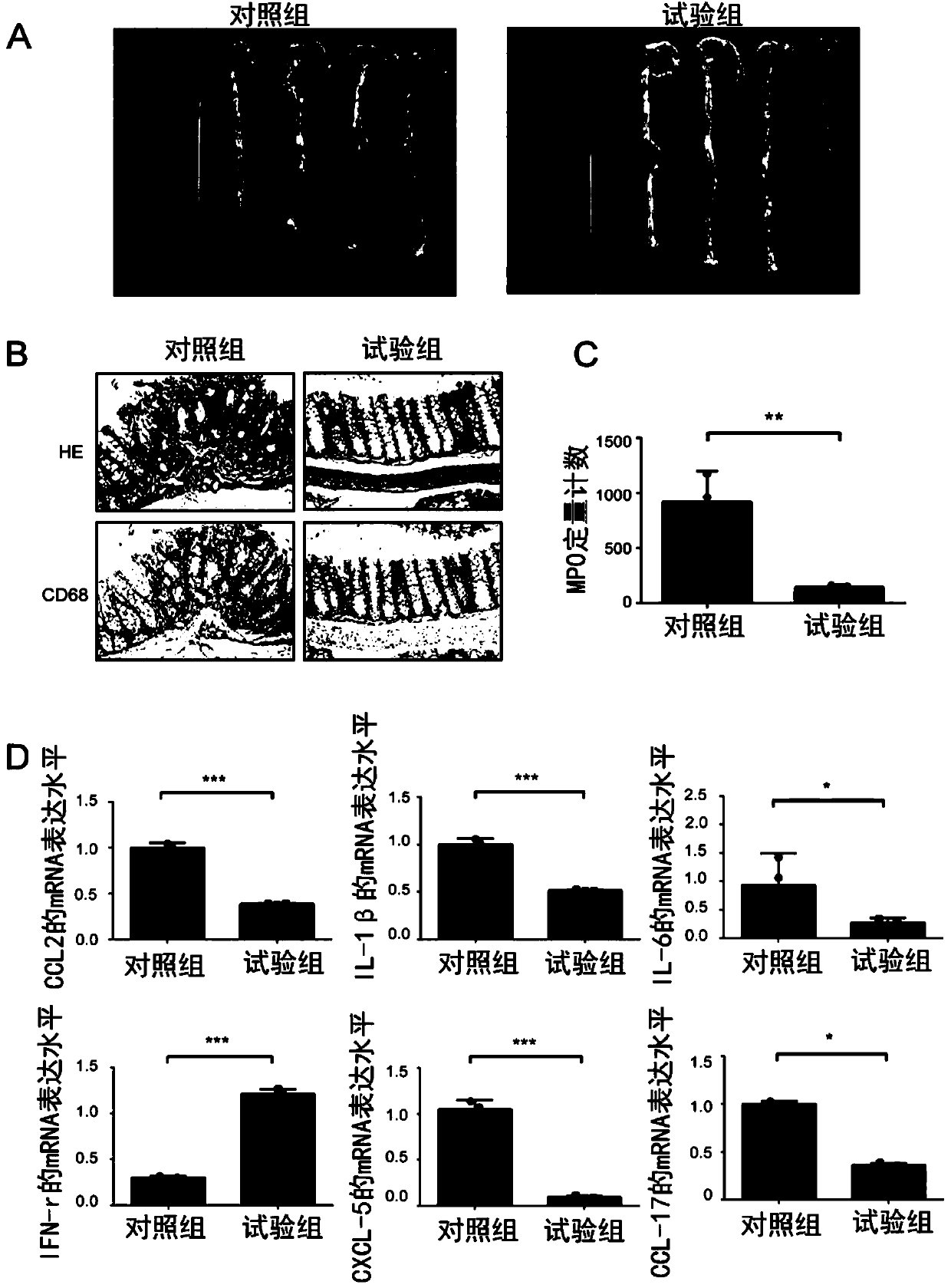

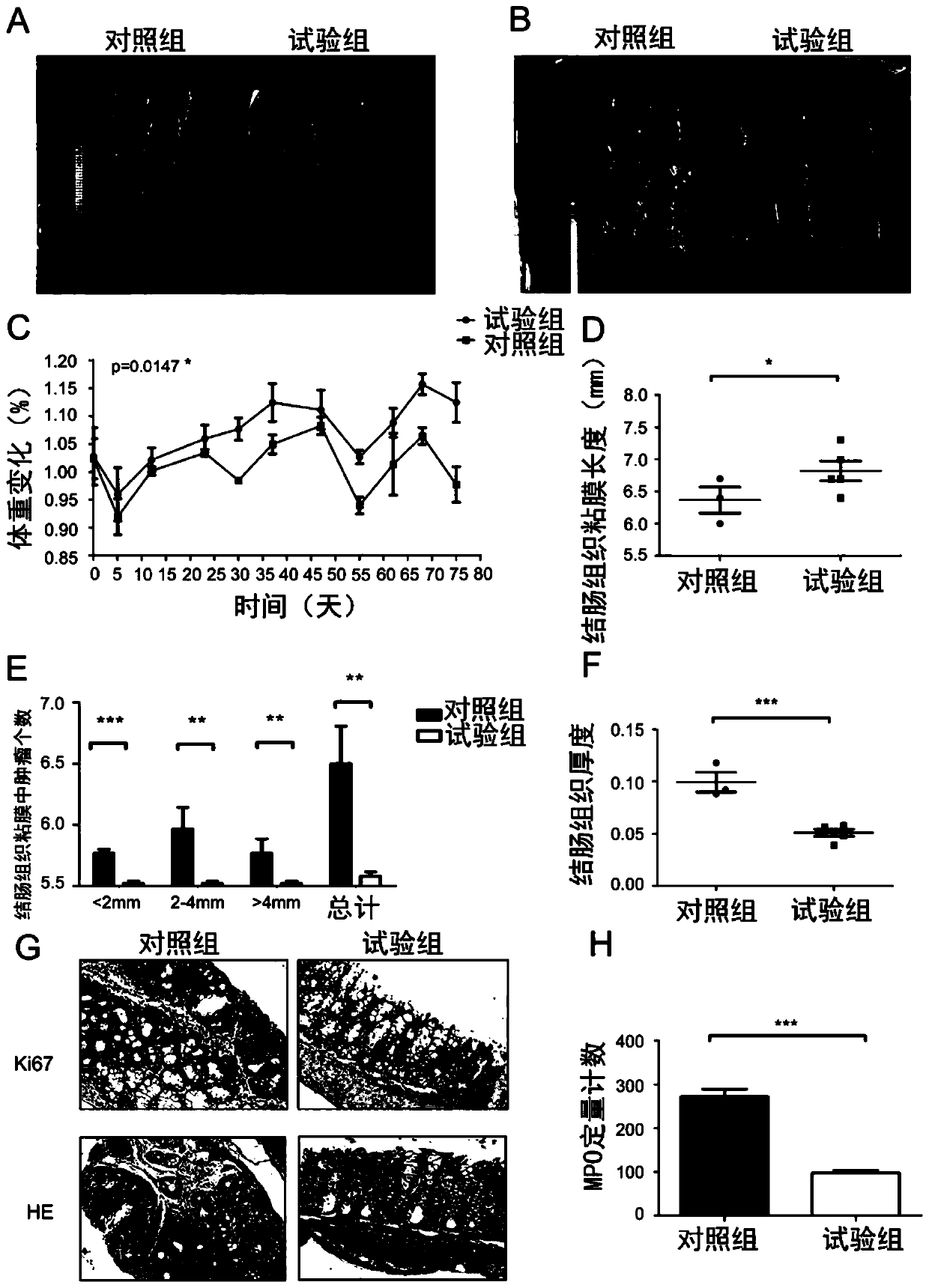

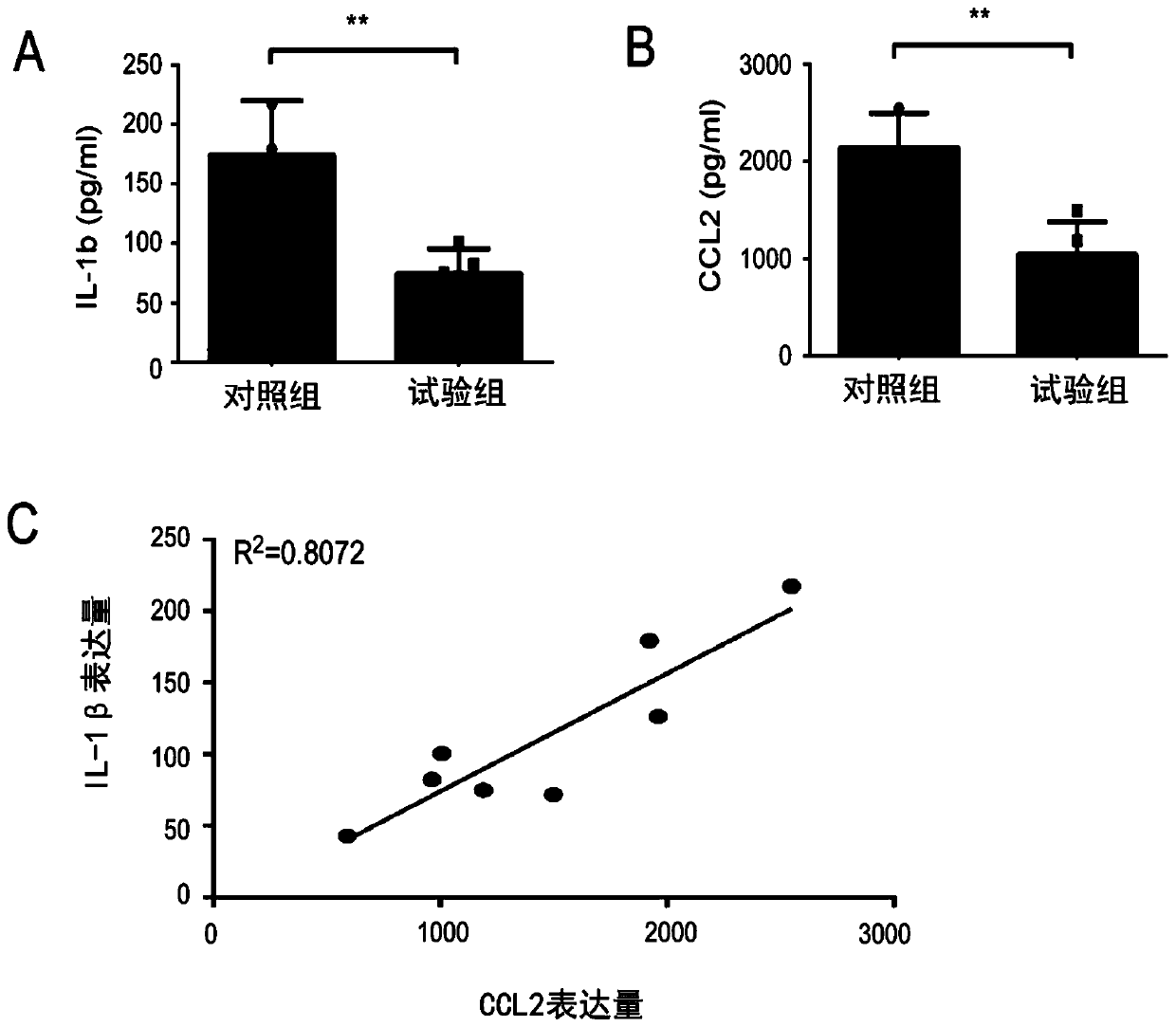

Application of dimethyl itaconate in prevention and treatment of ulcerative colitis and canceration of ulcerative colitis

ActiveCN110731955AReduce the risk of developing colon cancerDigestive systemEster active ingredientsDimethylitaconateColitis

The invention discloses an application of dimethyl itaconate in prevention and treatment of ulcerative colitis and canceration of the ulcerative colitis. Specific tests prove that the dimethyl itaconate can effectively prevent the ulcerative colitis and reduce the risk of development of colon cancer by the ulcerative colorectal, and provides novel ideas for the prevention and treatment of the ulcerative colitis and the canceration of the ulcerative colitis.

Owner:SUN YAT SEN UNIV +1

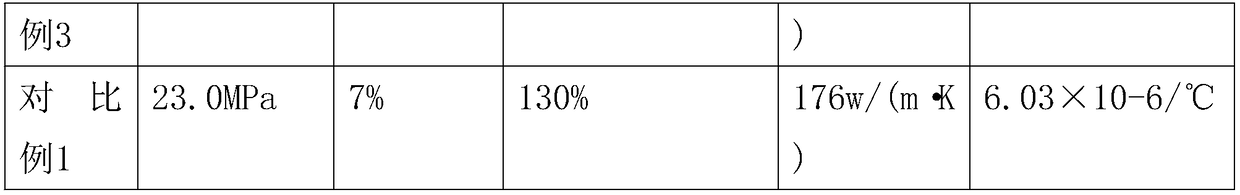

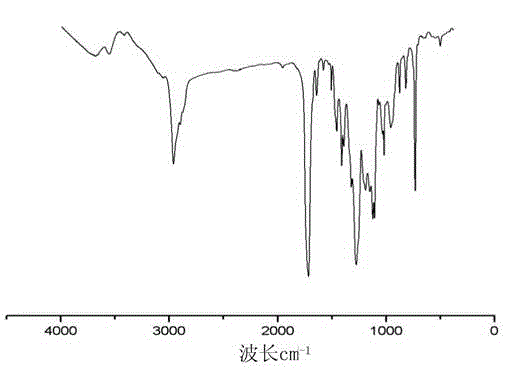

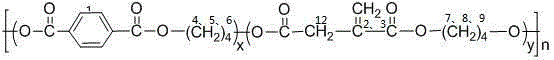

Method for preparing itaconic acids copolyester with macromolecular network structure

The invention provides a method for preparing itaconic acids copolyester with a macromolecular network structure. The method comprises the following steps: reacting a component a, a component b and component c under the action of an esterifying catalyst, wherein the component a is dimethyl itaconate, the component b is 1, 4-butanediol, and the component c is at least one of aromatic dibasic acid, aromatic dibasic acid ester and aromatic dibasic acid anhydride; via atactic copolymerization, leading aromatic chain segment into itaconic acid polyester chain segments, and adding styrene as a crosslinking agent for crosslinking under the action of benzoyl peroxide (BPO) as an initiating agent to obtain the polyester with the macromolecular network structure. Through the adoption of the method, the mechanical property and the thermodynamic property of itaconic acid polyester are improved, the synthetic process is simple, the operation is easy, and the obtained polyester has certain biodegradability.

Owner:QINGDAO UNIV OF SCI & TECH

Aluminum-based composite heat dissipation material for LED

InactiveCN104789823AImprove sinterabilityImprove sintering performanceHeat-exchange elementsBoron nitrideTitanium sulfate

The invention relates to an aluminum-based composite heat dissipation material for an LED. The aluminum-based composite heat dissipation material is prepared from raw materials in parts by mass as follows: 68-70 parts of aluminum, 8-12 parts of aluminum nitride, 3-5 parts of silicon nitride, 2-4 parts of boron nitride, 4-8 parts of niobium diselenide, 10-14 parts of cellulose, 4-8 parts of silicon carbide micro-powder, 2-6 parts of dimethyl itaconate, 2-4 parts of titanium sulfate, 2-6 parts of sodium carbonate,2-3 parts of zirconium oxide sol and 4-5 parts of an auxiliary, wherein the auxiliary is prepared from raw materials in parts by mass as follows: 3-6 parts of mineral oil, 12-14 parts of cryolite fine powder, 3-7 parts of zirconium acetate, 2-4 parts of citric acid, 6-10 parts of iron powder, 4-8 parts of copper powder and 2-6 parts of potassium fluoroaluminate. The aluminum-based composite heat dissipation material for the LED is firm, tough, high in environmental corrosion resistance capacity, not prone to corrosion and durable, and has good heat conduction and heat dissipation capacity; the surface is not prone to wear.

Owner:WUHU SHENLONG NEW ENERGY TECH

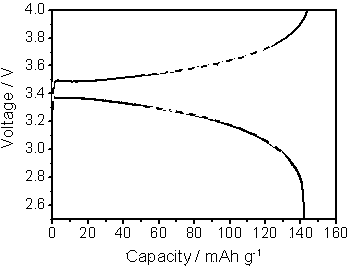

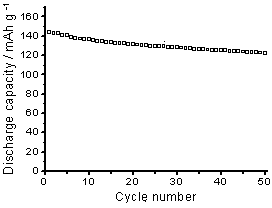

High-temperature resistance lithium ion secondary battery adhesive and preparation method thereof

The invention discloses a high-temperature resistance lithium ion secondary battery adhesive and a preparation method thereof. The preparation method adopts 2-acrylamide-2- methylsulfonate, itaconate, dimethyl itaconate, maleic anhydride, and fumarate as the initial monomer, and carboxymethyl cellulose salt as the auxiliary agent. The reactants polymerize under the inducing of persulfate thermal free radical initiator, so as to produce homogeneous and stable electrode adhesive. The electrode adhesive prepared according to the preparation method has the advantage of high-temperature resistance, and is suitable for being applied to high power-density and high energy-density lithium ion battery.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

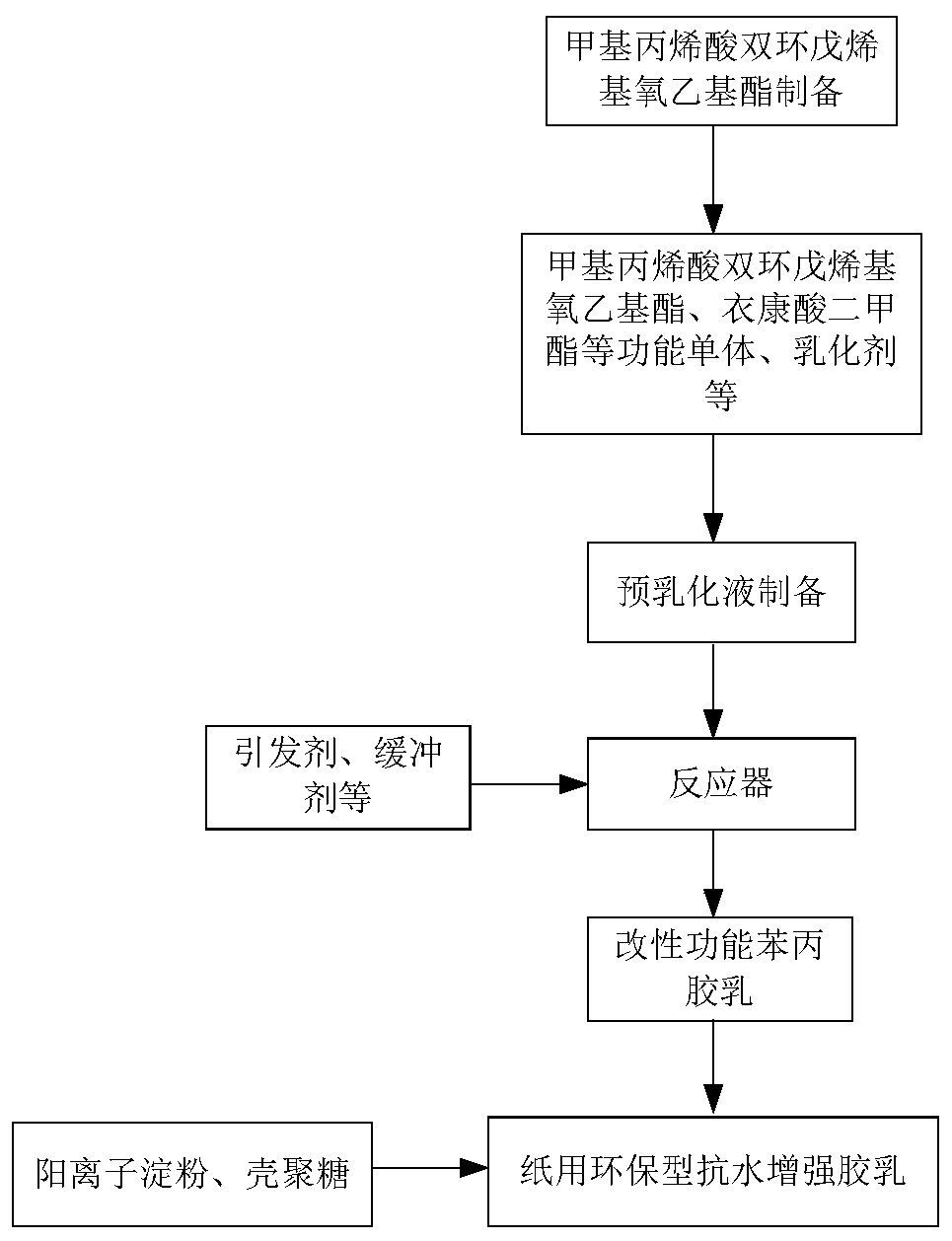

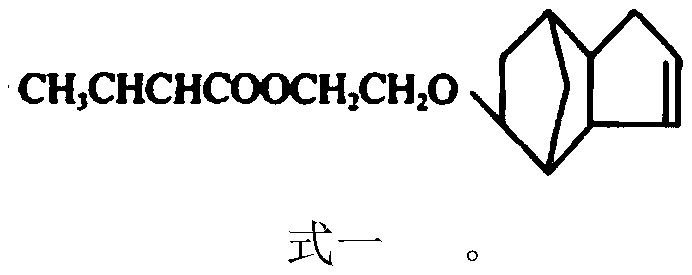

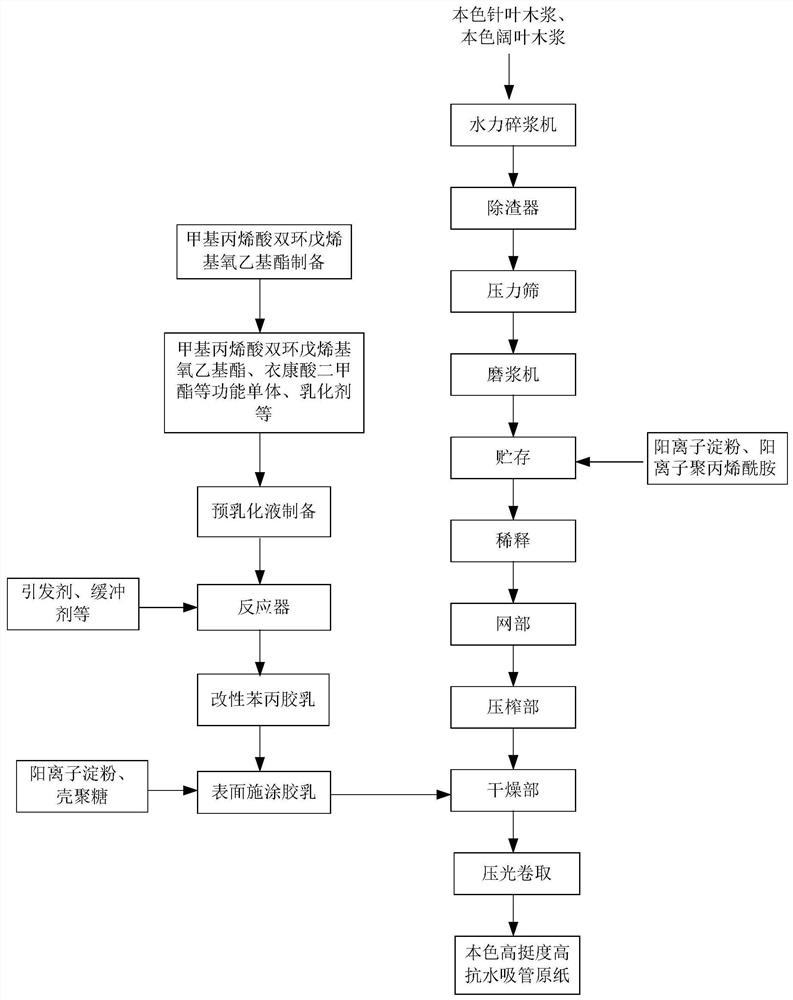

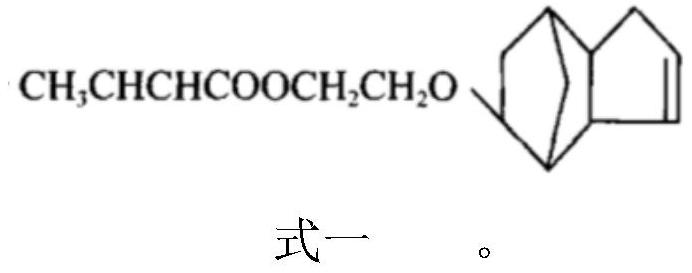

Environment-friendly water-resistant reinforced latex for paper as well as preparation method and application thereof

ActiveCN111533840AGood compatibilityImprove rigidityNatural cellulose pulp/paperWater-repelling agents additionSodium bicarbonateCyclopentene

The invention discloses environment-friendly water-resistant reinforced latex for paper as well as a preparation method and application thereof, and belongs to the field of production of auxiliaries for papermaking. According to the method, styrene, butyl acrylate and the like are used as main reaction monomers; dicyclopentenyl oxyethyl methacrylate and dimethyl itaconate are used as main functional monomers; sodium dodecyl sulfate and nonylphenol polyoxyethylene ether are adopted as emulsifiers, persulfate is adopted as an initiator, sodium bicarbonate is adopted as a buffer agent, and modified styrene-acrylic latex is synthesized through a pre-emulsification seed emulsion polymerization process, and is compounded with cationic starch and chitosan to prepare the environment-friendly water-resistant enhanced latex for paper. The environment-friendly water-resistant enhanced latex for the paper is advanced in process, free of pollution and low in production cost; and straw base paper prepared from the environment-friendly water-resistant enhanced latex for the paper is good in stiffness, water resistance, heat resistance and printability, has a certain antibacterial property, can reduce bacterial pollution on the surface of the straw base paper, and has a wide market application prospect.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

Impregnating resin for filter paper of engine oil filter element device

InactiveCN108103848AImprove filtering effectGood oil resistanceNon-macromolecular organic additionPaper/cardboardEpoxyPropanoic acid

The invention discloses impregnating resin for filter paper of an engine oil filter element device and relates to the technical field of filter element devices. The impregnating resin is prepared fromthe following components: water-soluble phenolic resin, dihydromethyl propionic acid, modified nano silicon dioxide, epoxy resin, dimethyl fumarate, dimethyl itaconate, modified sodium lignosulphonate and a plasticizer. The filter paper impregnated with the resin can keep good filtering performance; the impregnating resin does not cause a pore-blocking phenomenon on pores of the filter paper.

Owner:安徽新立滤清器有限公司

Novel heat sink material for semiconductors

InactiveCN105957951AImprove mechanical propertiesPoor insulation, low thermal conductivitySemiconductor devicesSodium metasilicatePtru catalyst

The invention discloses a novel heat sink material for semiconductors. The novel heat sink is prepared from the following raw materials: a base body and a wrapping layer, wherein the base body is prepared from the following raw materials: graphite, aluminum oxide, aluminum nitride, silicon carbide, carbon nano-tubes, silicon dioxide, montmorillonite, zinc oxide, sodium carbonate, zirconium dioxide sol, light calcium, cellulose, dimethyl itaconate, a binding agent, a coupling agent, a compatilizer, an antioxidant, a stabilizing agent, a bridging agent, a conditioning agent, an enhancer, a coacervating agent, a flexibilizer, a stabilizer and a terminating agent; and the wrapping layer is prepared from the following raw materials: silicon carbide fiber, graphene, silicon dioxide, silicon carbide, sodium metasilicate, carboxymethyl cellulose sodium, an initiator, a crosslinking agent, a softening agent, a tackifier, a catalyst and a fire retardant. The novel heat sink material for the semiconductors prepared by the invention has good mechanical performance, high insulativity and heat conductivity and relatively low expansion coefficient, and can be widely applied to LED heat conduction and heat radiation heat sink materials in semiconductor technology.

Owner:黄宇

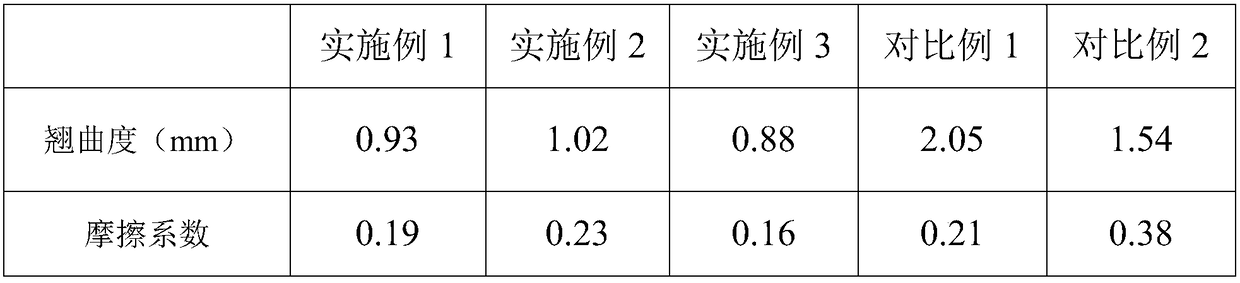

Antibacterial glass fiber reinforced polypropylene composite material and preparation method thereof

The invention provides an antibacterial glass fiber reinforced polypropylene composite material and a preparation method thereof. The composite material comprises the following components in parts byweight: 55-65 parts of polypropylene resin, 10-15 parts of long glass fibers, 20-30 parts of organic coating modified silicon carbide powder, 8-12 parts of tetrapod-shaped nano zinc oxide whiskers, 2-4 parts of dimethyl itaconate, 1.5-3.5 parts of an antibacterial agent, 1-3 parts of a titanate coupling agent, 6-12 parts of a toughening agent, 0.5-1.2 parts of a heat stabilizer, 0.2-0.8 part of anantioxidant and 0.6-1.8 parts of a lubricant. The preparation method comprises the following steps: adding the polypropylene resin, the long glass fiber accounting for 30-40% of the total mass, the titanate coupling agent, the toughening agent, the heat stabilizer, the antioxidant and the lubricant into a double-screw extruder through a main feeding port, and adding the rest components into the double-screw extruder from a lateral feeding port, and carrying out melting extrusion and granulation, wherein the extrusion temperature is 210-250 DEG C. The composite material not only has low warpage and good friction resistance, but also has good antibacterial performance.

Owner:安庆市泽烨新材料技术推广服务有限公司

Natural-color high-stiffness high-water-resistance straw base paper and preparation method thereof

ActiveCN111676728ASolve environmental problemsSolve the risk of carcinogenic substances such as dioxins brought inNatural cellulose pulp/paperSpecial paperCyclopentenePolymer science

The invention discloses a natural-color high-stiffness high-water-resistance straw base paper and a preparation method thereof, and belongs to the technical field of papermaking. The natural-color high-stiffness high-water-resistance straw base paper is prepared by uniformly coating a layer of environment-friendly water-resistance reinforced latex for paper on the surface of the straw base paper,drying, calendaring and coiling, wherein the basis weight of the natural-color high-stiffness high-water-resistance straw base paper is 60-100g / m<2>, the stiffness is 1.3-1.6 mN.m, the longitudinal dry tensile strength is 5.1-7.8 KN / m, the longitudinal wet tensile strength is 0.8-1.0 KN / m, the surface water absorption is 13-15g / m<2>, and the smoothness is 100-105s. The latex disclosed by the invention is prepared by taking dicyclopentenyl oxyethyl methacrylate and dimethyl itaconate as main functional monomers, adopting pre-emulsified seeded emulsion polymerization, and compounding the polymerwith cationic starch and chitosan. The method is advanced in process, free of pollution and low in production cost, and the prepared straw base paper is good in stiffness, water resistance, heat resistance and printability and has a certain antibacterial property.

Owner:浙江恒川新材料有限公司

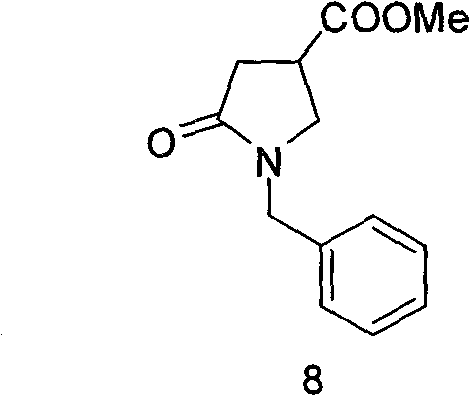

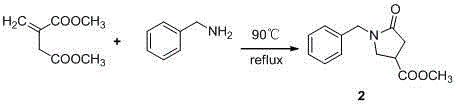

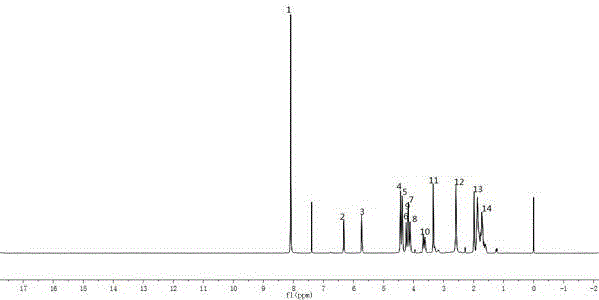

Practical synthesis method of 3-benzyl-3-aza-bicyclo[2,1,0]hexane

InactiveCN102432525ALow costSolve the shortcomings of low yield, complicated operation, difficult post-processing, and difficult to scale upOrganic chemistryMeth-Methanesulfonyl chloride

The invention relates to a practical synthesis method of 3-benzyl-3-aza-bicyclo[2,1,0]hexane. The method comprises the following synthesis processes of: condensing dimethyl itaconate, serving as a raw material, with benzylamine to obtain ester, and reducing to obtain alcohol; reacting the ester with methanesulfonyl chloride to generate methanesulfonyl ester; reacting the methanesulfonyl ester with lithium hexamethyl disilazide to obtain corresponding 3-benzyl-3-aza-bicyclo[2,1,0]hexane-2-one; and reducing by lithium aluminum hydride to obtain the 3-benzyl-3-aza-bicyclo[2,1,0]hexane. Due to the adoption of the method, the defects of low yield, complexity in operation, difficulty in post-treatment and amplification and the like in the conventional document process are overcome. The practical synthesis method of the 3-benzyl-3-aza-bicyclo[2,1,0]hexane provided by the invention has the advantages of simple synthesis route, reasonable process selection, low cost of the raw material, easiness in obtaining of the raw material, convenience for operation and post-treatment, high total yield, easiness in amplification, and application to large-scale production. In the method, the dimethyl itaconate serves as the raw material.

Owner:SUZHOU KANGRUN PHARMA

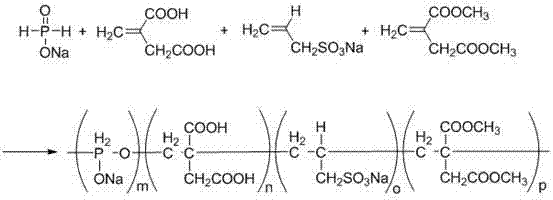

Dimethyl itaconate sulfonate multi-copolymer scale inhibitor and preparation method thereof

InactiveCN101955266BSimple production processLess residual monomerScale removal and water softeningChemical industrySludge

The invention relates to a dimethyl itaconate sulfonate multi-copolymer scale inhibitor and a preparation method thereof, which belong to the technical field of chemical industry. The scale inhibitor is prepared by performing aqueous polymerization on dimethyl itaconate, itaconic acid and sulfonate under an initiator system. Based on the mass of the itaconic acid, the adding amount of the sulfonate is between 10 and 50 percent, the adding amount of the dimethyl itaconate is between 5 and 100 percent, the initiator content is between 5 and 30 percent and sodium hypophosphite is between 5 and 30 percent. The itaconic acid serving as a raw material undergoes aqueous solution free radical polymerization with the dimethyl itaconate and the sulfonate in the presence of the initiator, so that production process is simple, the product has a small quantity of residual monomers and three wastes are not discharged. The polymer prepared by the method has efficient inhibitory action on the formation and attachment of fouling layers such as carbonate, sulphate, phosphate, silicate and the like in a cooling water system and plays a good role in dispersing iron oxide, sludge and the like.

Owner:山东省特种设备检验研究院淄博分院

Novel high performance heat sink material

InactiveCN106129239AImprove performanceImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesSodium metasilicateAntioxidant

The invention discloses a novel high performance heat sink material which is formed by a substrate and a wrapping layer. The substrate is prepared by graphite, yttrium oxide, aluminum nitride, silicon carbide, carbon nanotubes, silica, bentonite, vanadium oxide, calcium phosphate, zirconium dioxide sol, light calcium, cellulose, itaconic acid dimethyl ester, a binder, a coupling agent, a compatibilizer, an antioxidant, a stabilizer, a bridging agent, an adjusting agent, a reinforcing agent, a flocculation agent, a flexibilizer, a stabilizer, and a terminator. The wrapping layer is prepared by silicon carbide fibers, a graphene, silica, sodium metasilicate, hydroxymethyl cellulose sodium, an initiator, a cross-linking agent, a softener, an adhesion agent, a catalyst and a fire retardant. The prepared novel high performance heat sink material has good mechanical performance, excellent insulating performance, thermal conductivity and a low coefficient of expansion and can be widely applied to the LED heat conduction-heat radiation novel high performance heat sink material in the semiconductor technology.

Owner:黄宇

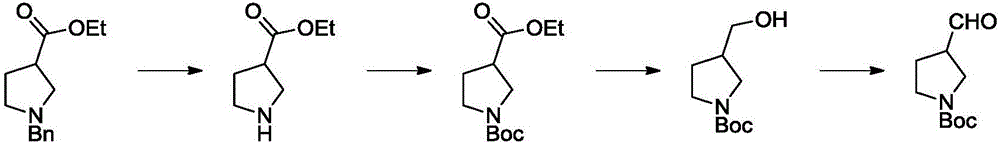

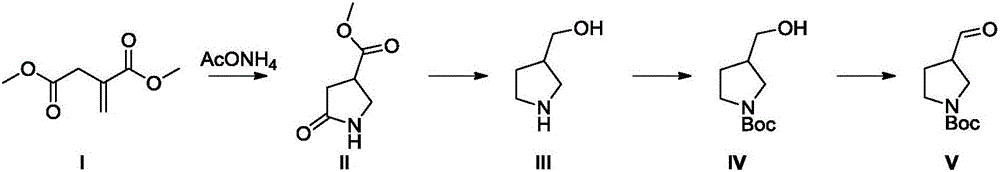

Method for synthesizing N-Boc-3-pyrrolidine formaldehyde

The invention discloses a method for synthesizing N-Boc-3-pyrrolidine formaldehyde. The method comprises that dimethyl itaconate as a raw material undergoes an intramolecular cyclization reaction to produce methyl 5-oxo-3-pyrrolidine carboxylate, then the methyl 5-oxo-3-pyrrolidine carboxylate undergoes a reduction reaction to produce pyrrolidine-3-methanol, then the pyrrolidine-3-methanol is subjected to Boc protection so that N-Boc-pyrrolidine-3-methanol is obtained, and finally, the N-Boc-pyrrolidine-3-methanol is oxidized to form a final product compound. The method is simple and convenient, has a low cost, content greater than 99%, produces small environmental pollution and is suitable for industrial production.

Owner:武汉恒和达生物医药有限公司

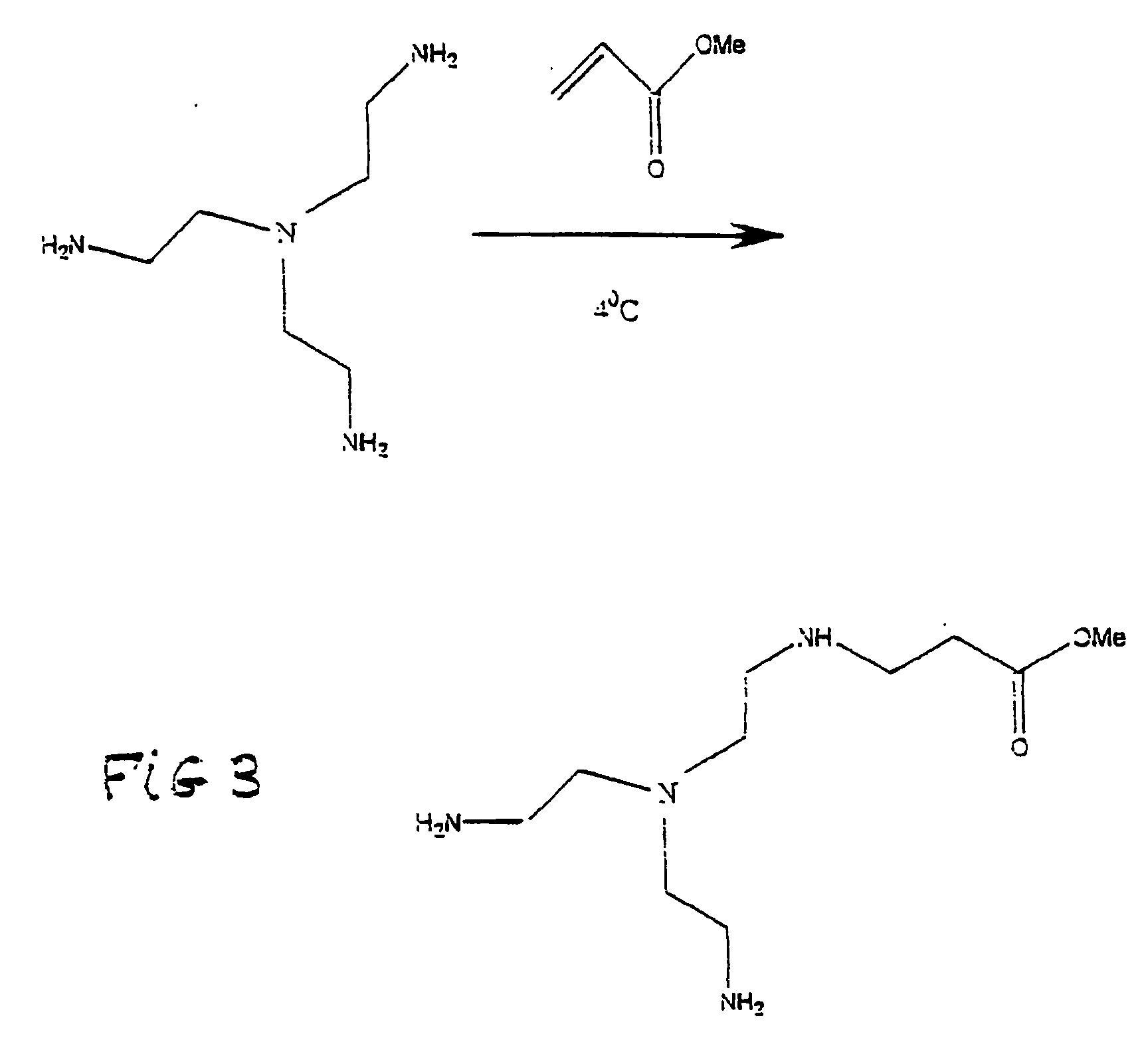

Hyperbranched (pamam) polymers via a one pot process

Methods of providing hyperbranched polymers by polymerization of appropriate AB2 monomers derived from the reaction of tris-(2-aminoethyl) amine and various other materials, namely, succinic anhydride, methyl acrylate, and dimethyl ita-conate.

Owner:DENDRITIC NANO TECH INC

Flame-retardant low-warpage glass fiber reinforced polypropylene composite material and preparation method thereof

The invention provides a flame-retardant low-warpage glass fiber reinforced polypropylene composite material and a preparation method thereof. The flame-retardant low-warpage glass fiber reinforced polypropylene composite material comprises the following components: polypropylene resin, alkali-free glass fiber, organic coated modified silicon carbide powder, four-needle nanometer zinc oxide whiskers, a halogen-free flame retardant, dimethyl itaconate, a titanate coupling agent, a toughening agent, a heat stabilizer, an antioxidant and a lubricant. The preparation method comprises the followingsteps: adding polypropylene resin, alkali-free glass fiber accounting for 30-40% of the total mass, the titanate coupling agent, the halogen-free flame retardant, the toughening agent, the heat stabilizer, the antioxidant and the lubricant into a twin-screw extruder from a main feed port, adding the organic coated modified silicon carbide powder, dimethyl itaconate and the remaining alkali-free glass fiber into the twin-screw extruder from a side feed port, and performing melt extrusion and granulation, wherein the extrusion temperature is 205-245 DEG C. The composite material not only has relatively good low warpage and friction resistance, but also has very good flame retardant properties.

Owner:安庆市泽烨新材料技术推广服务有限公司

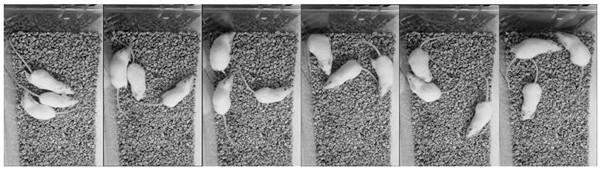

Construction method of double-disease model mouse

ActiveCN112586452AScreening economyQuick filterAgainst vector-borne diseasesAnimal husbandryDiseasePhysical medicine and rehabilitation

The invention provides a construction method of a double-disease model mouse. Dimethyl itaconate is dissolved in double distilled water, the concentration is 1.5 mM, the mouse is fed, new water is replaced every two days, and the feeding time is 15-20 days; and during the period of spontaneous type 1 diabetes mellitus, intensive water drinking is carried out once a week, the time is 2 days, and the double-disease model mouse is finally obtained. By means of the model, the injury of a motion function of the model can be easily detected, the injury includes motion retardation, muscular stiffness, static tremor and other main symptoms of PD, the success rate is high, and the model stabilization time is long.

Owner:FUJIAN ACAD OF MEDICAL SCI

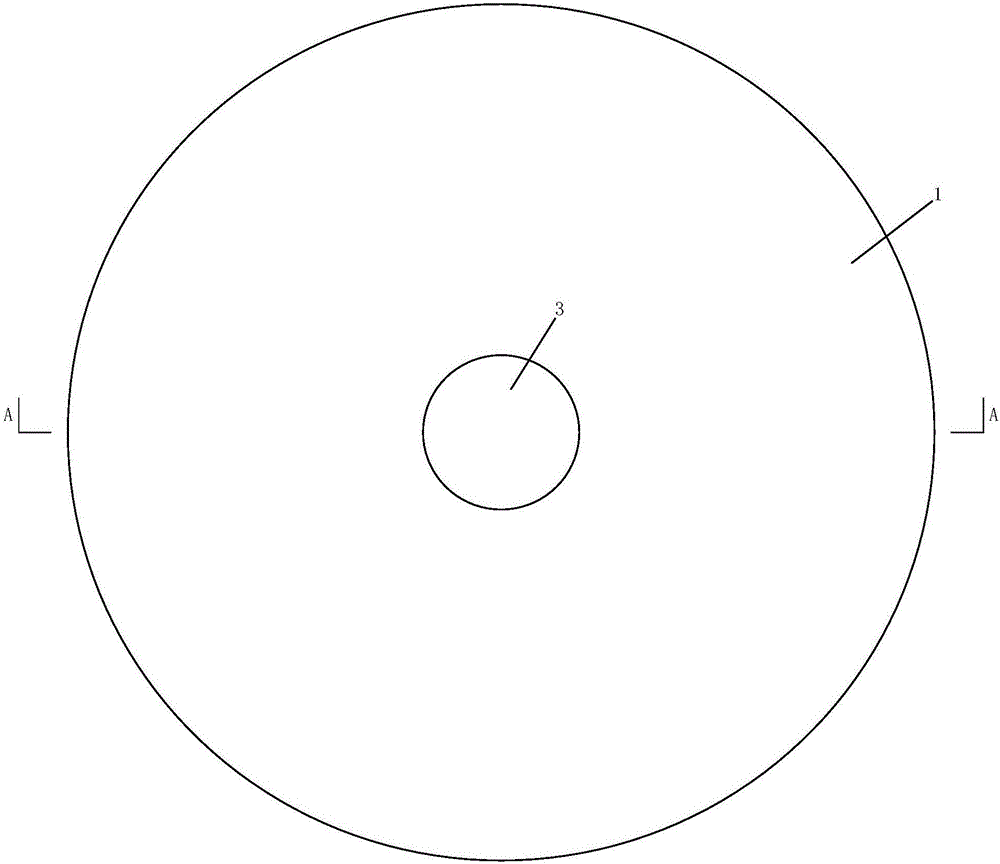

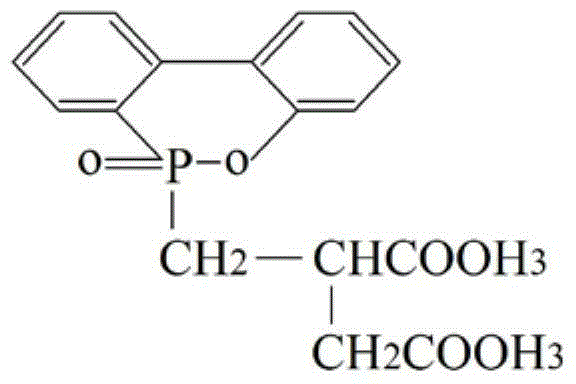

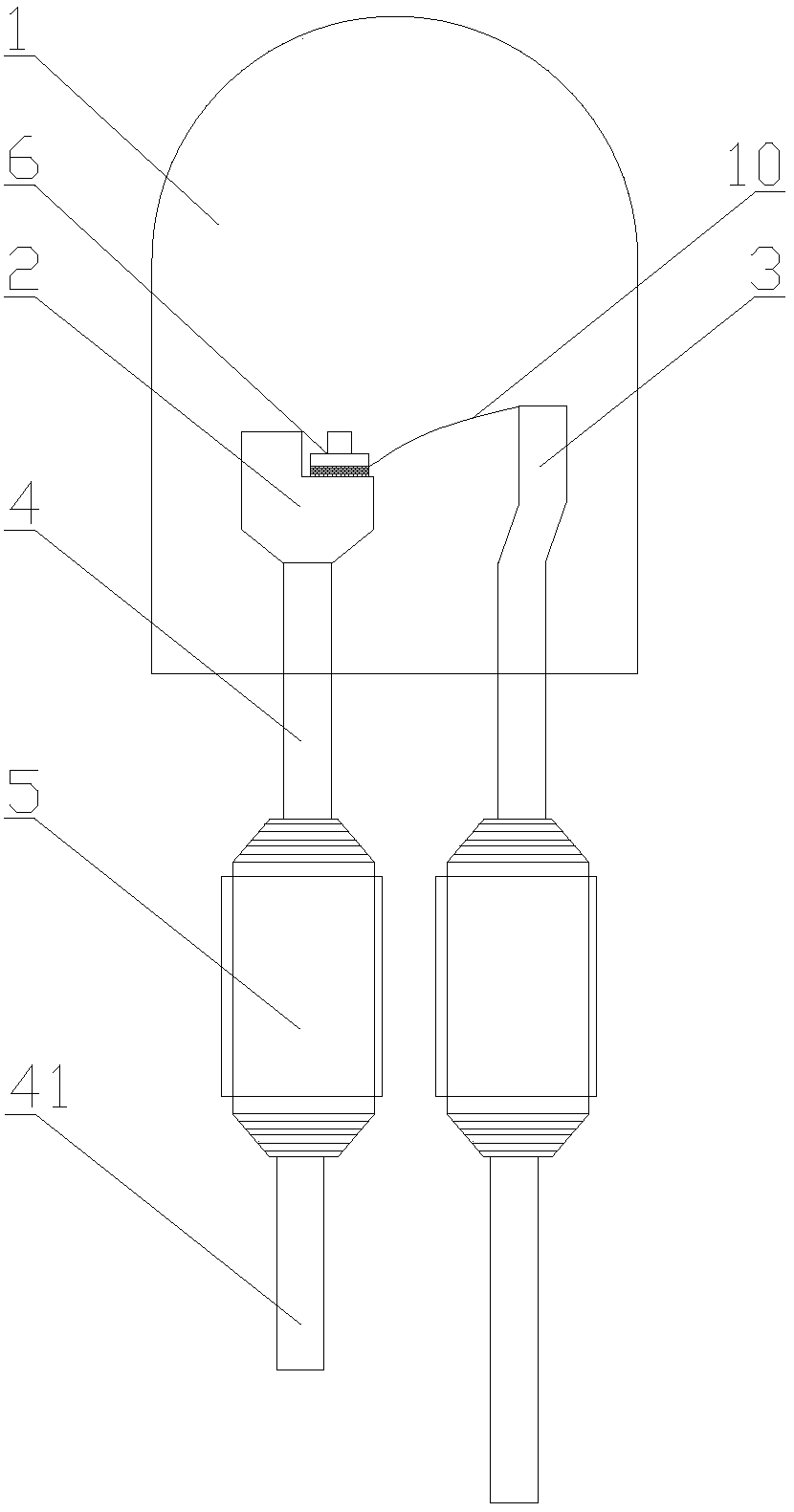

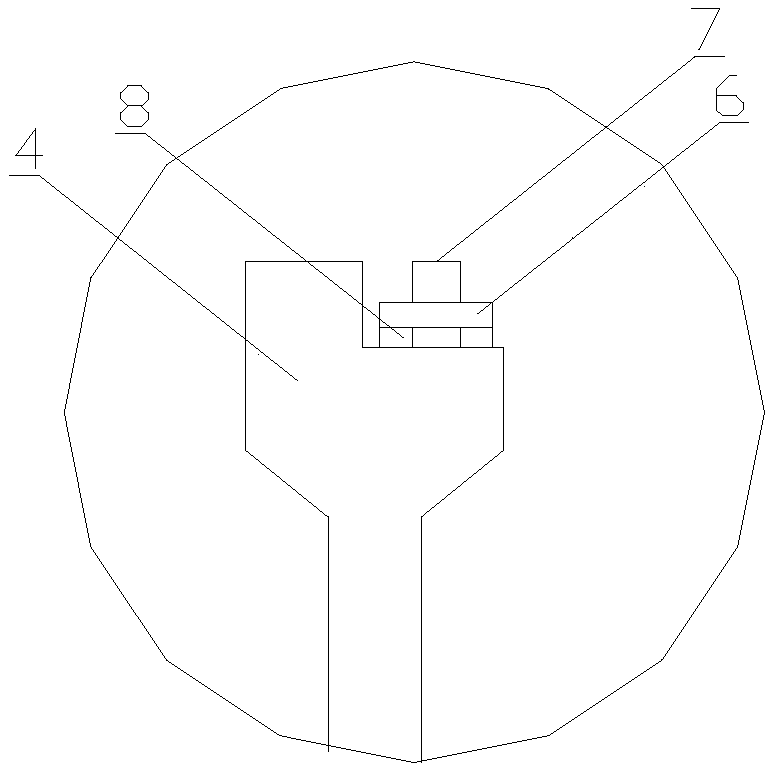

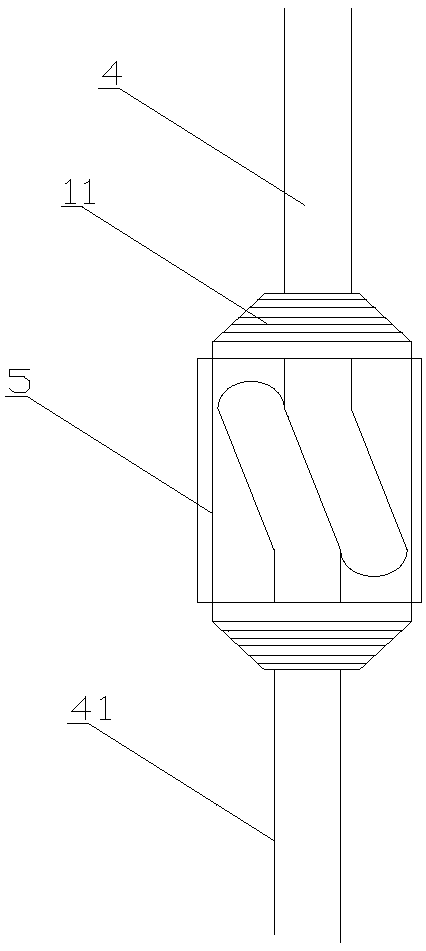

Halogen-free flame-retardant macromolecular damping spring and preparation method thereof

The invention discloses a halogen-free flame-retardant macromolecular damping spring which is prepared by mixing dimethyl terephthalate, 9,10-dihydro-9-oxo-10-phosphaphenanthrene-10-oxide-dimethyl itaconate, 1,4-butanediol, polytetrahydrofuran, a catalyst and an antioxidant; adding all the components into a polymerization kettle according to a certain ratio; carrying out transesterification and condensation polymerization reaction to obtain a polyether-co-ester elastomer, wherein the polyether-co-ester elastomer has the hardness of D50-D60, and the polyether-co-ester elastomer is proven to have number-average molecular weight of 29000-32000 through GPC tests realized by using a trichloromethane solvent; and carrying out injection molding on the polyether-co-ester elastomer to obtain the macromolecular damping spring with structure and elastomer material bearing and rebounding effects. The halogen-free flame-retardant macromolecular damping spring has the advantages that the production process is simple, the production efficiency is high, the product percent of pass is relatively high, and the halogen-free and flame-retardant requirements are met, so that the halogen-free flame-retardant macromolecular damping spring can be widely used as a buffering device in the fields of vehicles, engineering machines, elevators and the like.

Owner:HANGZHOU HONGSHENG TECH CO LTD

Low-warpage polypropylene composite and preparation method thereof

The invention provides a low-warpage polypropylene composite and a preparation method thereof. The low-warpage polypropylene composite comprises 60-70 parts of polypropylene resin, 10-15 parts of continuous glass fibers, 10-15 parts of ethylene propylene diene monomers, 20-30 parts of organic coated modified silicon carbide powder, 8-12 parts of tetrapod-like nano-zinc oxide whiskers, 2-4 parts ofdibutyl itaconate, 1-3 parts of titanate coupling agent, 6-12 parts of toughening agent, 0.5-1.2 parts of heat stabilizer, 0.2-0.8 part of antioxygen and 0.6-1.8 parts of lubricant. The preparation method includes: adding the polypropylene resin, the continuous glass fibers, 30-40% by mass of the whole ethylene propylene diene monomers, the titanate coupling agent, the toughening agent, the heatstabilizer, the antioxygen and the lubricant into a double-screw extruder through a main feeding port, adding the other ingredients into the double-screw extruder through a side feeding port, and melting and extruding to pellet at a temperature of 200-240 DEG C. The low-warpage composite has the advantages of good low warpage and good friction resistance.

Owner:安庆市泽烨新材料技术推广服务有限公司

Heat sink material for semiconductors

InactiveCN106058029AImprove performanceImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesSodium metasilicateSic fiber

The invention discloses a heat sink material for semiconductors, which comprises a substrate and a wrapping layer. The substrate is made of the following raw materials: graphite, aluminum oxide, aluminum nitride, silicon nitride, a nanometer carbon tube, silicon dioxide, kaolin, magnesium oxide, sodium carbonate, zirconium dioxide, light calcium, cellulose, dimethyl itaconate, binders, coupling agents, compatibilizers, anti-oxidants, tranquilizers, bridging agents, conditioning agents, reinforcing agents, coagulants, toughening agents, stabilizers, and terminating agents. The wrapping layer is made of the following raw materials: silicon carbide fiber, graphite, silicon dioxide, silicon nitride, sodium metasilicate, sodium cellulose glycolate, initiators, crosslinking agents, softening agents, adhesion agents, catalysts, and fire retardants. The heat sink material of the invention has good mechanical properties, excellent insulation, thermal conductivity and low expansion coefficient, and can be widely applied to heat sink material for LED heat guiding and radiating in semiconductor technology.

Owner:黄宇

Heat sink material with high thermal matching performance for semiconductor lighting

The invention provides a heat sink material with high thermal matching performance for semiconductor lighting and relates to the technical field of semiconductor lighting. The heat sink material comprises graphene, boron oxide, alundum powder, a nickel conductive adhesive, barium titanate, sodium chloride, citric acid, chromic anhydride, magnesium oxide, polyurethane, calcium oxide, diatomite, hydroxyapatite, zirconium dioxide sol, rare earth, grape seed extract, dimethyl itaconate, a bonding agent, a coupling agent, a compatibilizer, an antioxidant and a stabilizing agent. The heat sink material with high thermal matching performance for semiconductor lighting, provided by the invention has good comprehensive performance and good mechanical property, excellent insulating property and thermal conductivity, and lower coefficient of expansion, can effectively improve the thermal matching ability and can be widely applied to a semiconductor technology.

Owner:安徽普发电气有限公司

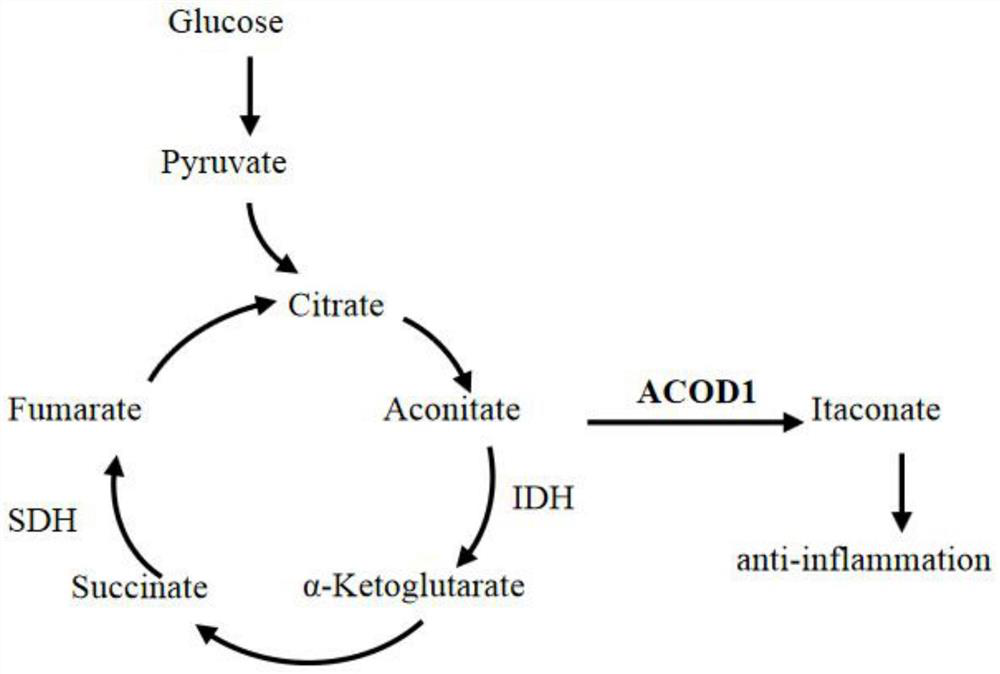

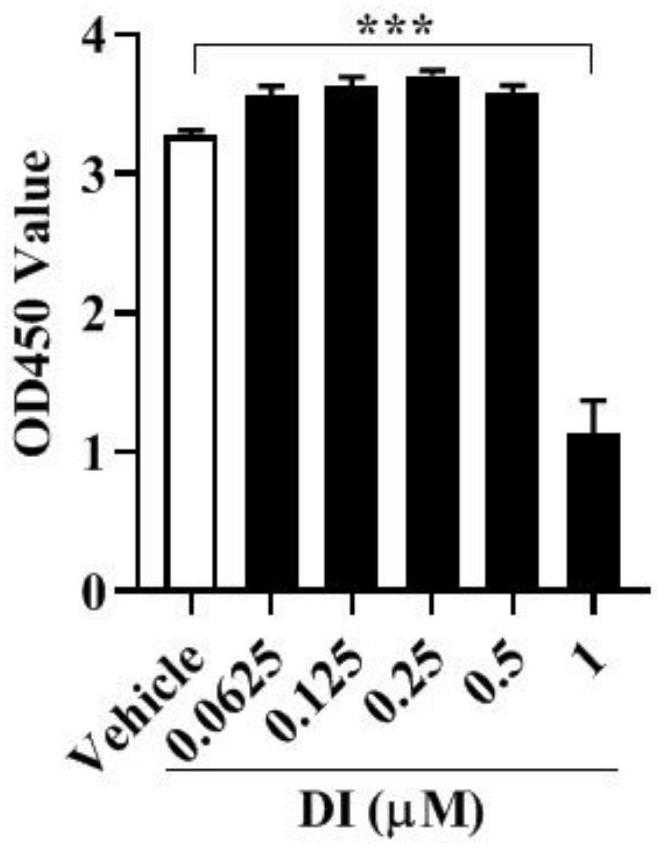

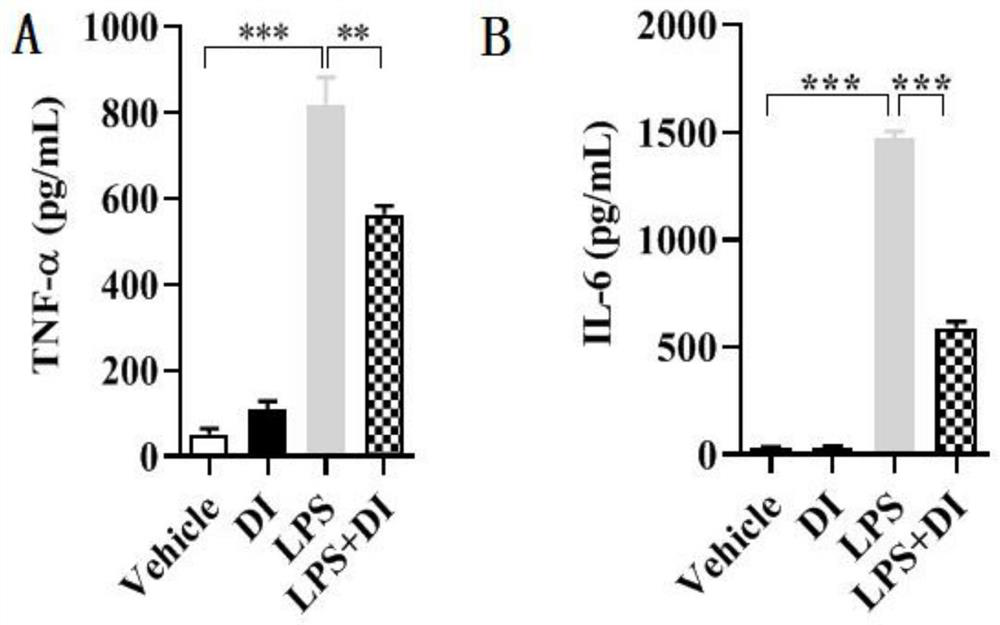

Application of dimethyl itaconate in preparation of medicine for treating and/or preventing neurodegenerative diseases

PendingCN113662934APrevention of Cognitive Impairment DiseasesPrevent neuroinflammatory responsesOrganic active ingredientsNervous disorderPharmaceutical drugDimethylitaconate

The invention belongs to the technical field of drugs for treating degenerative diseases, and relates to application of dimethyl itaconate in preparation of a medicine for treating and / or preventing neurodegenerative diseases. Experiments prove that the dimethyl itaconate can alleviate the decline of learning and memory ability and the damage of synaptic ultrastructures, and reduce neuroinflammation.

Owner:XUZHOU MEDICAL UNIV

Glass fiber reinforced AES resin material and preparation method thereof

The invention discloses a glass fiber reinforced AES resin material and a preparation method thereof. The glass fiber reinforced AES resin material is prepared from the following ingredients in parts by weight: 50-90 parts of acrylonitrile-ethylene propylene diene rubber-styrene, 10-40 parts of glass fibers, 3-10 parts of compatibilizer, 0.5-2 parts of coupling agent and 1-5 parts of dimethyl itaconate. The glass fiber reinforced AES resin material prepared by the preparation method has excellent tensile and bending properties and balanced flowability and impact properties. Due to the use of the glass fibers, the cost of the AES material is reduced, and the range of use of the AES material can be wider. The preparation method disclosed by the invention is simple and easy to implement. According to the glass fiber reinforced AES resin material and the preparation method thereof, a synergetic effect is achieved among the added dimethyl itaconate, the compatibilizer SMA (styrene-maleic anhydride copolymer) and the coupling agent, and the interfacial bonding strength between the AES and the glass fibers can be maximized, so that the mechanical properties of the material can be improved, and particularly the impact resistance of the material can be improved greatly.

Owner:HEFEI GENIUS NEW MATERIALS

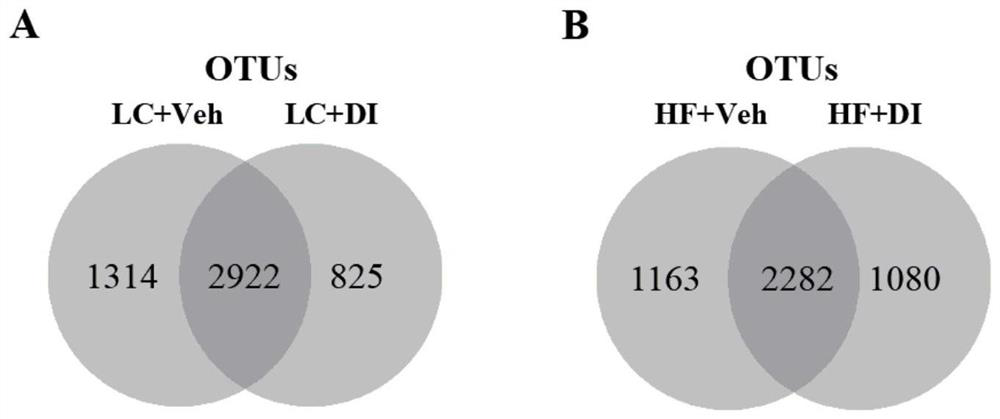

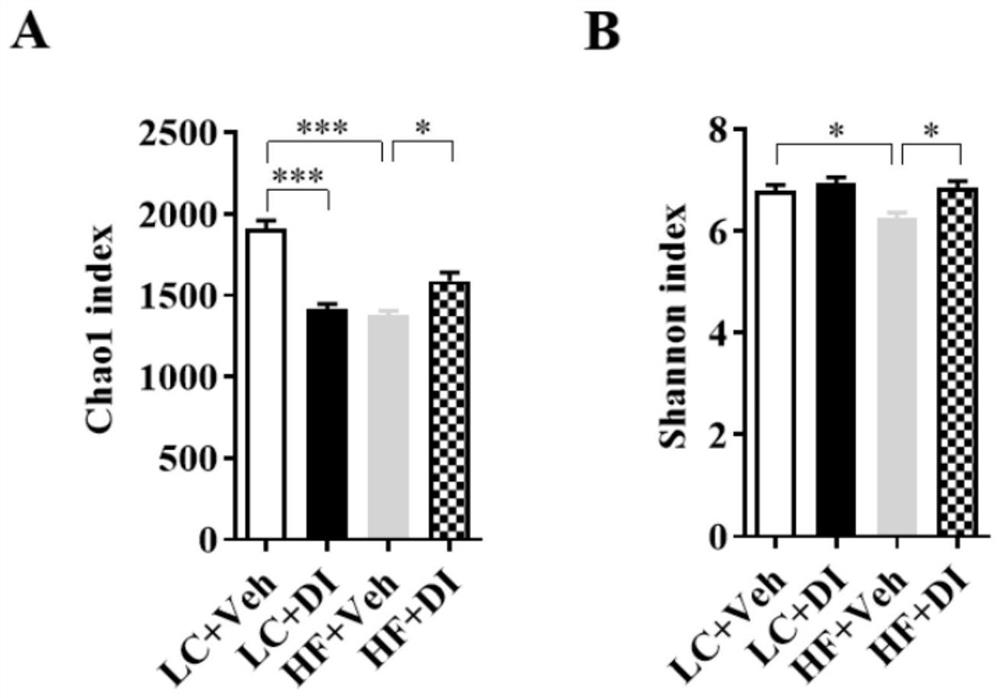

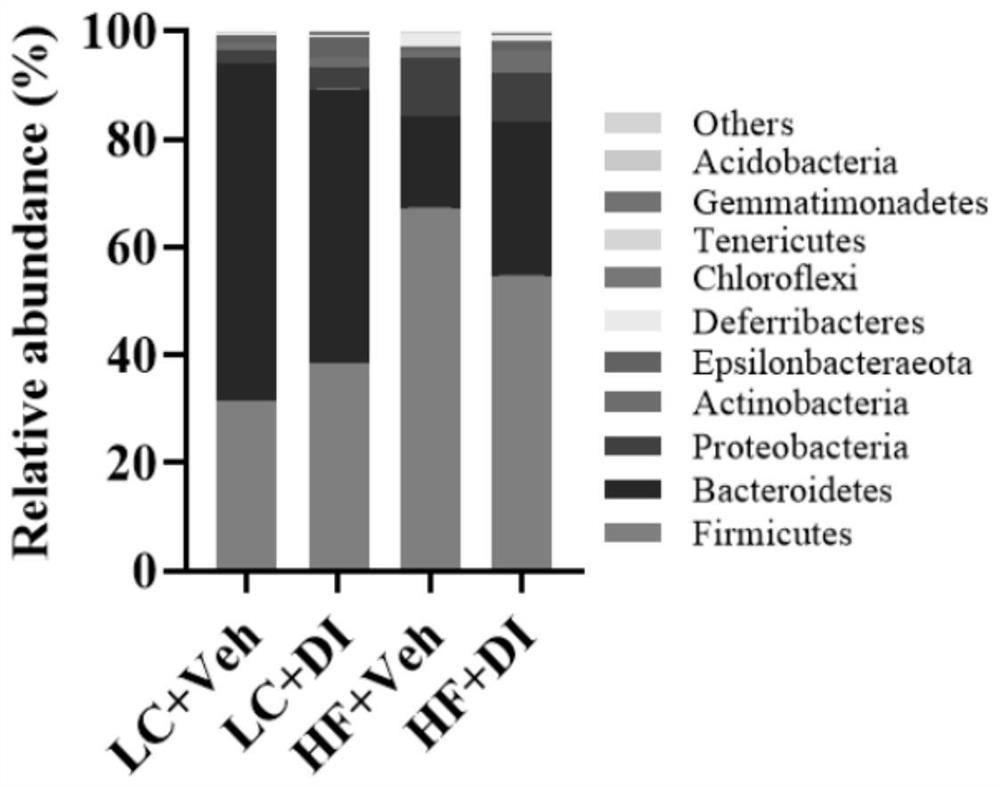

Application of dimethyl itaconate in preparation of medicine for preventing and/or treating obesity-induced intestinal micro ecological disorder

PendingCN114028375AAvoid dissonanceImprove obesityOrganic active ingredientsMetabolism disorderIntestinal inflammationObesity prevention

The invention relates to an application of dimethyl itaconate in the preparation of a medicine for treating and / or preventing obesity-induced intestinal micro ecological disorder. Experiments prove that dimethyl itaconate can correct intestinal micro ecological imbalance of obese mice, reduce intestinal inflammation and maintain intestinal barrier integrity.

Owner:XUZHOU MEDICAL UNIV

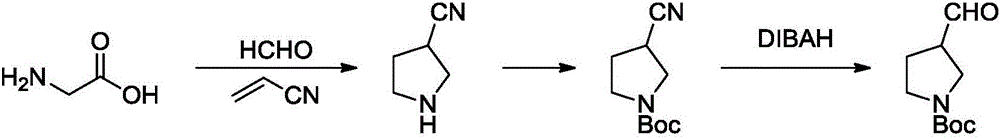

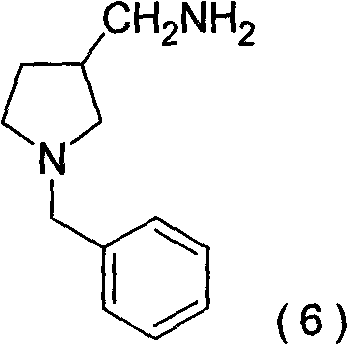

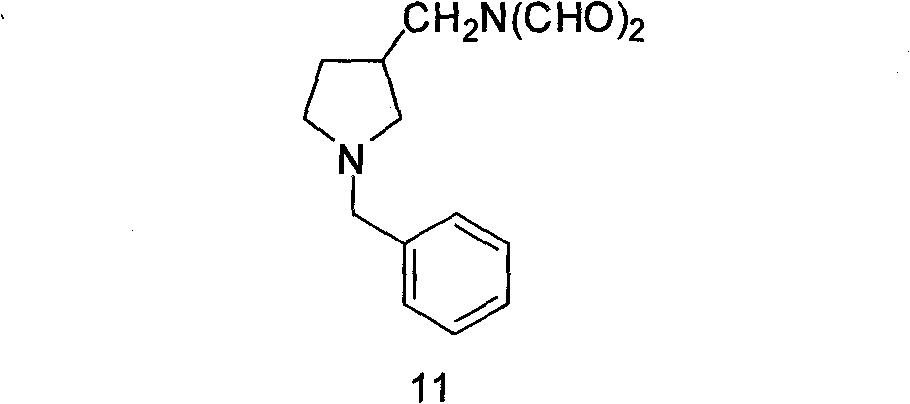

Preparation method of N-substituted 3-aminomethyl pyrrolidine

InactiveCN101906060AHigh yieldSimple and fast operationOrganic chemistryTert-Butyloxycarbonyl protecting groupDimethylitaconate

The invention discloses a preparation method of N-substituted 3-aminomethyl pyrrolidine. 1-benzyl-3-aminomethyl pyrrolidine and 3-tertiary-butoxy carbonyl-aminomethyl pyrrolidine are prepared by using polydiallyl itaconate and benzylamine as the raw materials through the reaction in seven steps of cyclization, reduction, substitution, hydrolyzation, protection, hydrogenation, and the like. The invention has the advantages of low-cost and easily-obtained raw materials, temperate reaction condition, simple operation process, low cost and the high yield.

Owner:江苏国华生物科技有限公司 +1

Abrasion-resistant optical material and preparation method thereof

InactiveCN107556443AStrong environmental corrosion resistanceNot easy to rustGlass fiberDimethylitaconate

Owner:宝鸡圭彬光电设备有限公司

Glass fiber reinforced rigidity-and-toughness-balanced polyester composition and preparation method thereof

The invention discloses a glass fiber reinforced rigidity-and-toughness-balanced polyester composition and a preparation method thereof. The glass fiber reinforced rigidity-and-toughness-balanced polyester composition is prepared from the following ingredients in parts by weight: 100 parts of polyester, 1-5 parts of dimethyl itaconate, 20-100 parts of glass fibers, 0.1-0.5 part of antioxidant, 0.1-0.5 part of lubrication modifier and 0.1-0.2 part of coupling agent. The composition disclosed by the invention has excellent impact resistance while having very high strength and is an engineering plastic with relatively good rigidity and toughness balance; and the process for preparing the composition is simple and easy to operate, the processing formability is good, products are easy in demolding, and the surface appearance of the workpieces is good.

Owner:HEFEI GENIUS NEW MATERIALS

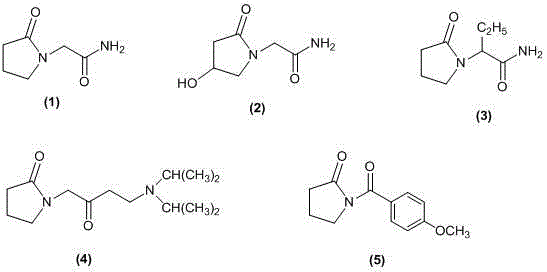

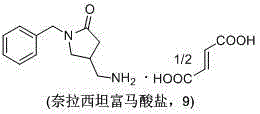

Preparation method for nebracetam

InactiveCN104402791AGood curative effectLittle side effectsOrganic chemistryPyrrolidinonesCarboxylic acid

The invention discloses a preparation method for nebracetam, and belongs to the technical field of medical chemistry. The key points of the technical scheme of the invention are as follows: the preparation method for the nebracetam comprises the following steps: performing Michael addition reaction and intramolecular cyclization on dimethyl itaconate and benzylamine serving as raw materials to obtain 1-benzyl-5-oxopyrrolidin-3-carboxylic methyl ester; reducing the 1-benzyl-5-oxopyrrolidin-3-carboxylic methyl ester by sodium borohydride to obtain 1-benzyl-4-hydroxymethyl-pyrrolidine-2-keton; performing methyl sulfonylation on the 1-benzyl-4-hydroxymethyl-pyrrolidine-2-keton to obtain 1-benzyl-5-oxopyrrolidin-3-carboxylic methanesulfonate; finally, performing ammonification and reduction on the 1-benzyl-5-oxopyrrolidin-3-carboxylic methanesulfonate by using ammonia water to obtain the nebracetam. The preparation method is simple in preparation process, easy to control and high in target product yield, and meets the requirement for green chemistry.

Owner:重庆奥舍生物化工有限公司

Heat sink material used for light emitting diode for high-luminance semiconductor illumination

InactiveCN108281538AImprove performanceImprove mechanical propertiesSemiconductor devicesSodium metasilicateAntioxidant

The invention discloses a heat sink material used for a light emitting diode for high-luminance semiconductor illumination, and relates to the technical field of semiconductor illumination. The heat sink material comprises graphene, carbon nanotubes, silicon carbide, silver conductive adhesive, vanadium oxide, calcium carbonate, carboxymethyl cellulose sodium, aluminium oxide particles, magnesiumoxide, antimonous oxide, sodium metasilicate, bentonite, calcium phosphate, zirconium dioxide sol, light weight calcium, cellulose, dimethyl itaconate, a binder, a coupling agent, a compatilizer, an antioxidant and a stabilizing agent. The heat sink material has high comprehensive performance and mechanical performance, excellent insulativity and heat conductivity and relatively low expansion coefficient, and can be widely applied to the heat sink material used for the light emitting diode for high-luminance semiconductor illumination in the semiconductor technology.

Owner:安徽普发电气有限公司

Novel heat sink material

InactiveCN106206922AImprove mechanical propertiesImprove insulation performanceSemiconductor devicesSodium BentoniteSodium metasilicate

The invention discloses a novel heat sink material, which is prepared from the following raw materials: a matrix and a wrapping layer, wherein the matrix is prepared from the following raw materials: graphite, yttrium oxide, aluminum nitride, silicon carbide, a carbon nanotube, silicon dioxide, bentonite, zinc oxide, calcium carbonate, zirconium dioxide sol, lightweight calcium, cellulose, dimethyl itaconate, a binder, a coupling agent, a compatilizer, an antioxidant, a stabilizing agent, a bridging agent, a regulator, an enhancer, a flocculation agent, a flexibilizer, a stabilizer and a terminating agent; and the wrapping layer is prepared from the following raw materials: a silicon carbide fiber, graphene, silicon dioxide, silicon carbide, sodium metasilicate, carboxymethyl cellulose sodium, an initiator, a cross-linking agent, a softening agent, a tackifier, a catalyst and a fire retardant. The prepared novel heat sink material has good mechanical property, excellent insulativity and thermal conductivity and a relatively low expansion coefficient, and can be widely applied to LED heat conduction and heat dissipation in a semiconductor technology.

Owner:黄宇

Composition for LED lamp holder

The invention relates to a composition for an LED lamp holder. The composition comprises the following components by mass: 10 to 15 parts of graphite flake, 15 to 25 parts of zinc oxide, 8 to 15 parts of silica, 5 to 8 parts of modified corn starch, 2 to 6 parts of kaolin, 2 to 6 parts of dimethyl itaconate, 10 to 20 parts of modified purple sand powder, 2 to 6 parts of tea vinyl acetate, 4 to 8 parts of silicon carbide powder, 2 to 6 parts of Chinese medical stone powder, 2 to 6 parts of expanded graphite powder, 1 to 3 parts of boron nitride, 2 to 6 parts of sodium fluosilicate, 2 to 8 parts of lignin, 2 to 4 parts of wood plastic powder and 2 to 6 parts of cellulose. The components of the composition are simple; and through addition of the modified corn starch, the prepared lamp holder has good resistance to damp and corrosion, can bear high voltage without electric leakage and has excellent thermal diffusivity.

Owner:WUHU SHENLONG NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Practical synthesis method of 3-benzyl-3-aza-bicyclo[2,1,0]hexane Practical synthesis method of 3-benzyl-3-aza-bicyclo[2,1,0]hexane](https://images-eureka.patsnap.com/patent_img/f77a7cf7-30d7-4bef-b160-4de4ffa88eb7/745541DEST_PATH_IMAGE001.PNG)