A kind of ruthenium dioxide catalyst of methane oxychlorination and preparation method thereof

A ruthenium dioxide and catalyst technology, applied to the ruthenium dioxide catalyst of methane oxychlorination and the field of preparation thereof, can solve the problems of volatile loss, low selectivity of monochloromethane, low reaction temperature, etc., and achieve strong C-H bond activation capacity, high chloromethane selectivity, high methane conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

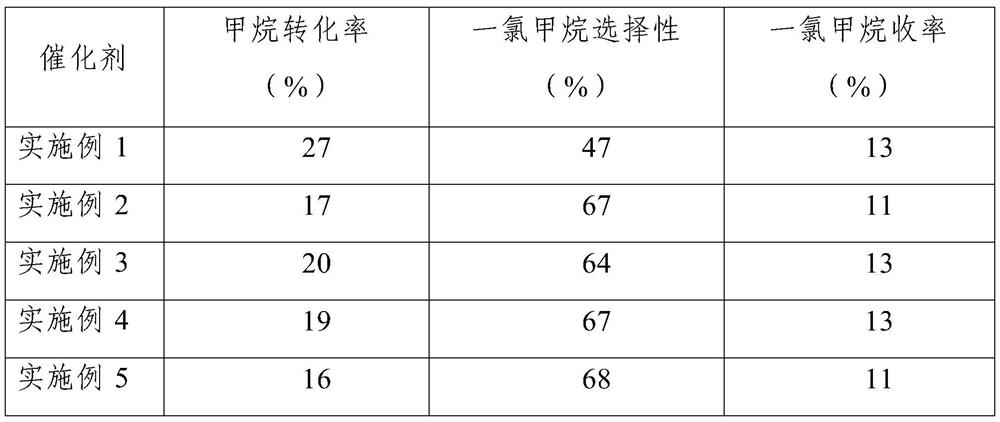

Embodiment 1

[0031] The catalyst of this embodiment includes a carrier, an active component loaded on the carrier, a catalytic component and a carrier modification aid, the mass content of titanium dioxide in the carrier is 100%, and the titanium dioxide is rutile crystal type titanium dioxide , the active component is ruthenium dioxide, the mass of ruthenium element in the ruthenium dioxide is 6.7% of the mass of the catalyst, and the catalytic promoter contains potassium chloride and lanthanum oxide, and the potassium chloride The mass of the potassium element in the lanthanum oxide is 0.03% of the mass of the catalyst, the mass of the lanthanum element in the lanthanum oxide is 1.85% of the mass of the catalyst, and the support modification auxiliary agent is silica, and in the silica The mass of the silicon element is 0.01% of the mass of the catalyst, and the molar ratio of the ruthenium element in the ruthenium dioxide, the potassium element in the potassium chloride and the lanthanum...

Embodiment 2

[0041] The catalyst of this embodiment includes a carrier, an active component loaded on the carrier, a catalytic component and a carrier modification aid, the mass content of titanium dioxide in the carrier is 93.22%, and the crystal form of the titanium dioxide is rutile A mixed crystal form of crystal form and anatase crystal form, the mass content of rutile crystal form titanium dioxide in the titanium dioxide of the mixed crystal form is 80%, the active component is ruthenium dioxide, and the ruthenium in the ruthenium dioxide The quality of the element is 1.2% of the mass of the catalyst, and the catalyst-promoting component contains potassium chloride and lanthanum oxide, and the mass of the potassium element in the potassium chloride is 0.2% of the mass of the catalyst, and the lanthanum oxide The mass of the lanthanum element in the medium is 2.5% of the mass of the catalyst, the support modification aid is silicon dioxide, the mass of the silicon element in the silica...

Embodiment 3

[0051] The catalyst of this embodiment includes a carrier, an active component loaded on the carrier, a catalytic component and a carrier modification aid, the mass content of titanium dioxide in the carrier is 93.22%, and the titanium dioxide is rutile crystal type titanium dioxide , the active component is ruthenium dioxide, the quality of the ruthenium element in the ruthenium dioxide is 2.5% of the mass of the catalyst, the catalytic promoter contains sodium chloride and lanthanum oxide, the chloride The quality of the sodium element in the sodium is 0.2% of the mass of the catalyst, the mass of the lanthanum element in the lanthanum oxide is 0.96% of the mass of the catalyst, the support modification auxiliary agent is silicon dioxide, and the silicon dioxide The quality of the silicon element in the middle is 0.13% of the catalyst quality, and the mol ratio of the ruthenium element in the ruthenium dioxide, the sodium element in the sodium chloride in the alkali metal com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com