Marine anti-corrosion anti-fouling composite coating and preparation method thereof

A composite coating and anti-fouling technology, which is applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve the problems of low bonding strength and the insulation of the ceramic layer needs to be improved, and achieve good bonding strength, Excellent long-term corrosion protection effect and close thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) The metal substrate is a 304 stainless steel rectangular test piece with a size of 30mm×15mm×1.25mm. Pretreatment of the surface of the metal substrate to be sprayed: sandblasting, ultrasonic cleaning, compressed air drying;

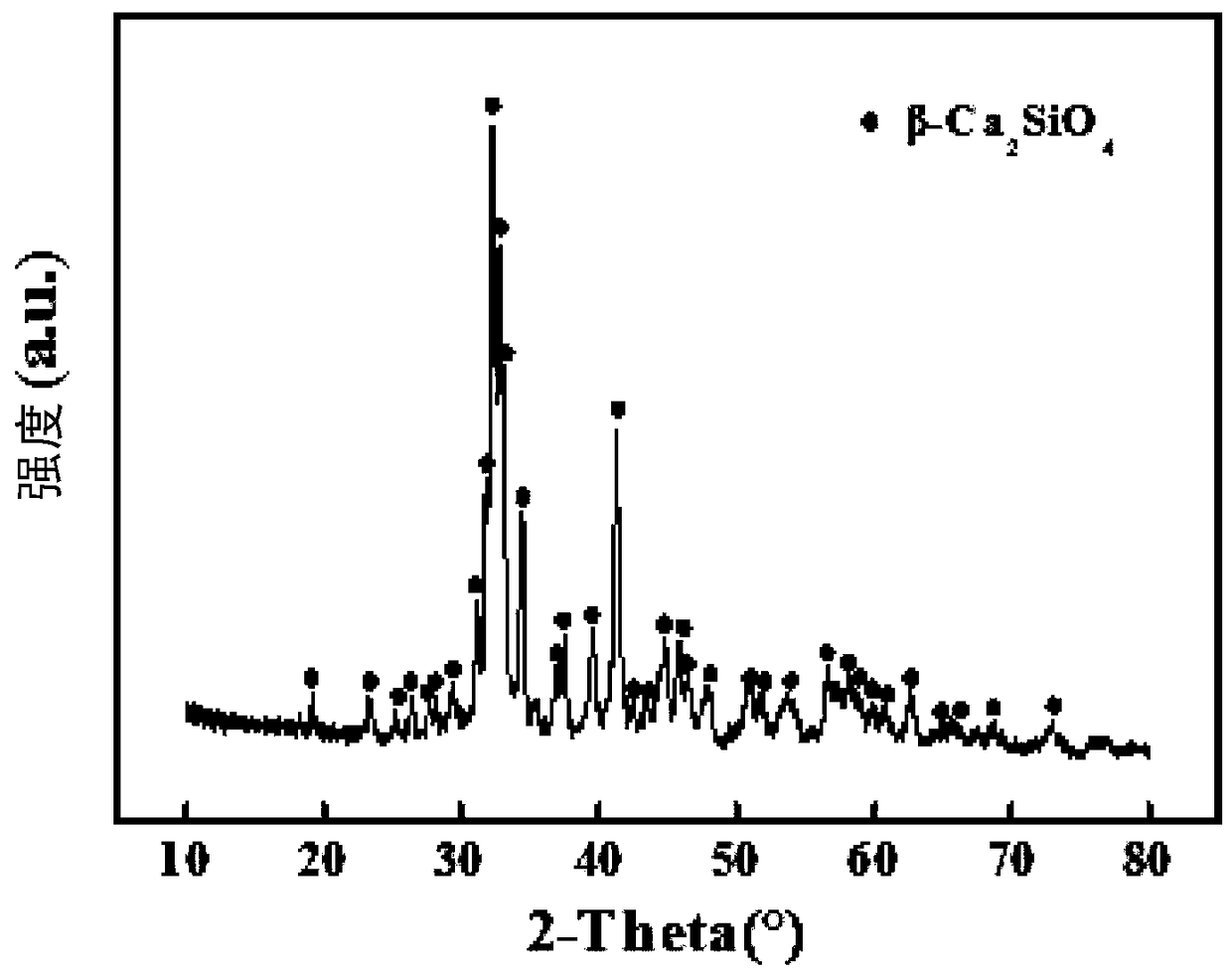

[0046] (2) Atmospheric plasma spraying: The atmospheric plasma spraying process is used to spray a 20 μm NiCr transition layer and a 130 μm dicalcium silicate coating on the surface pretreated metal substrate. Among them, using NiCr powder as raw material, the process parameters of spraying NiCr transition layer are: plasma gas argon gas flow rate 57slpm, plasma gas hydrogen gas flow rate 8slpm, spraying current 600A, voltage 74V, powder feeding tube diameter 1.8mm, spraying distance 120mm, Spraying time is 6 minutes. Using γ-dicalcium silicate powder as raw material, the process parameters of spraying dicalcium silicate coating are: plasma gas argon flow rate 49slpm, plasma gas hydrogen flow rate 9slpm, spraying current 650A, voltage 74V, po...

Embodiment 2

[0048] The sample obtained in Example 1 was soaked in 3.5wt% NaCl solution for 30 days. Figure 2-4 The SEM photos of the cross-section of the sample before and after immersion show that the porosity of the dicalcium silicate coating decreases after immersion, indicating that the coating has self-sealing properties.

Embodiment 3

[0050] The preparation method is the same as in Example 1, except that a 300 μm copper alloy coating is sprayed on the dicalcium silicate coating. Using copper-nickel alloy powder as raw material, the process parameters for spraying copper alloy coating are: plasma gas argon flow rate 57slpm, plasma gas hydrogen flow rate 7slpm, spraying current 580A, voltage 74V, powder feeding tube diameter 1.8mm, spraying distance 130mm , spraying time 25 minutes. The sample prepared in Example 3 was subjected to a salt spray corrosion test, using a sodium chloride solution with a concentration of 5.0 wt%, and at 35±2°C, alternating dry and wet cycles (spray for 24 hours, stop spraying for 24 hours). Figure 5 (a) and (b) are photos of the samples after 100h and 1000h salt spray corrosion respectively. It can be seen from the figure that after 1000 hours of salt spray corrosion, no obvious galvanic corrosion was found in the sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com