A pressure sensor based on organic field effect tube and its preparation method

A technology of pressure sensor and effect tube, which is applied in the field of pressure sensor based on organic field effect tube and its preparation, can solve problems such as environmental pollution and complex manufacturing process, achieve excellent adsorption performance, improve adhesion, and improve the effect of pressure sensing response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A preparation method based on an organic field effect tube pressure sensor, comprising the steps of:

[0041] Step 1. Clean the substrate with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0042]Step 2, by a method in vacuum thermal evaporation, magnetron sputtering, plasma-enhanced chemical vapor deposition, screen printing, printing and spin coating, metal nanowire grid electrodes, metal nanowires are prepared on the substrate surface For iron nanowires, copper nanowires, silver nanowires, gold nanowires, aluminum nanowires, nickel nanowires, cobalt nanowires, manganese nanowires, cadmium nanowires, indium nanowires, tin nanowires, tungsten nanowires and platinum one of the nanowires;

[0043] Step 3, ultrasonically mix bamboo cellulose and biodielectric material in proportion, and pass the mixed bamboo cellulose and biodielectric material solution through one of spin coating, roller coating, drop fi...

Embodiment 1

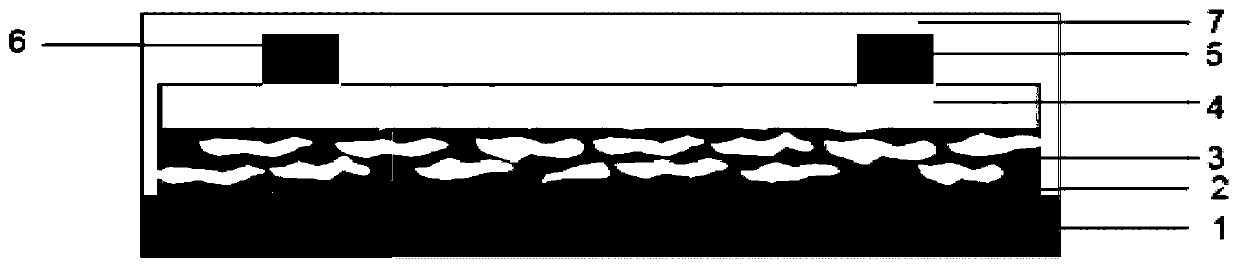

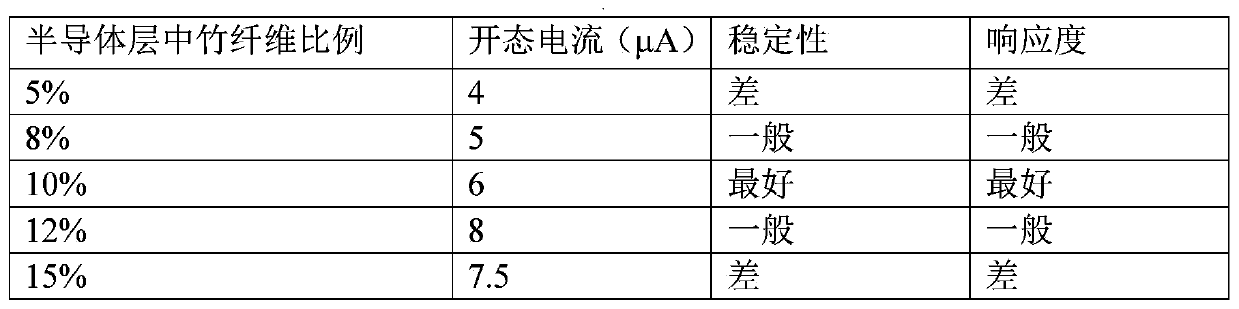

[0049] A pressure sensor based on an organic field effect tube, such as figure 1 The bottom-gate-top-contact structure is shown. The material and thickness of each layer are as follows: the gate electrode, source electrode and drain electrode are all silver nanowires, and the dielectric layer is made of a mixed material of bamboo cellulose and gelatin, with a thickness of 200nm. Bamboo cellulose accounts for 60%, the semiconductor layer is formed by mixing indigo and bamboo fiber (10%), the thickness is 50nm, and the shellac encapsulation layer has a thickness of 300nm. A field-effect transistor pressure sensor with high sensitivity and high stability can be realized with this structure, and its preparation method is as follows:

[0050] 1. Clean the substrate with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0051] 2. Preparation of silver nanowire grid electrodes on the surface of the substrate;

[0052] ...

Embodiment 2

[0057] Such as figure 1 The bottom gate top contact structure is shown, the material and thickness of each layer are: the gate electrode, source electrode and drain electrode are all gold nanowires, the dielectric layer is made of a mixed material of bamboo cellulose and silk protein, and the thickness is 500nm. Wherein the bamboo cellulose accounts for 70%, the semiconductor layer is composed of carotene and bamboo fiber (50% in content), the thickness is 70nm, and the thickness of the shellac encapsulation layer is 200nm. A field-effect transistor pressure sensor with high sensitivity and high stability can be realized with this structure, and its preparation method is as follows:

[0058] 1. Clean the substrate with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0059] 2. Preparation of gold nanowire grid electrodes on the surface of the substrate;

[0060] 3. Ultrasonic mixing of bamboo cellulose and silk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com