Preparation method and application of iron doped cobalt diselenide compound nitrogen doped carbon material

A technology of cobalt diselenide and nitrogen-doped carbon, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high cost and scarcity, limit large-scale application, etc., to improve utilization efficiency, facilitate industrial operation, The effect of a simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The carbon fiber paper with a geometric area of 2 square centimeters was ultrasonically cleaned with dediluted hydrochloric acid, ethanol, and deionized water for 30 minutes in order to remove impurities such as metal ions and organic substances on the surface. Place in an oven, dry at 50°C for 12 hours, and set aside.

Embodiment 2

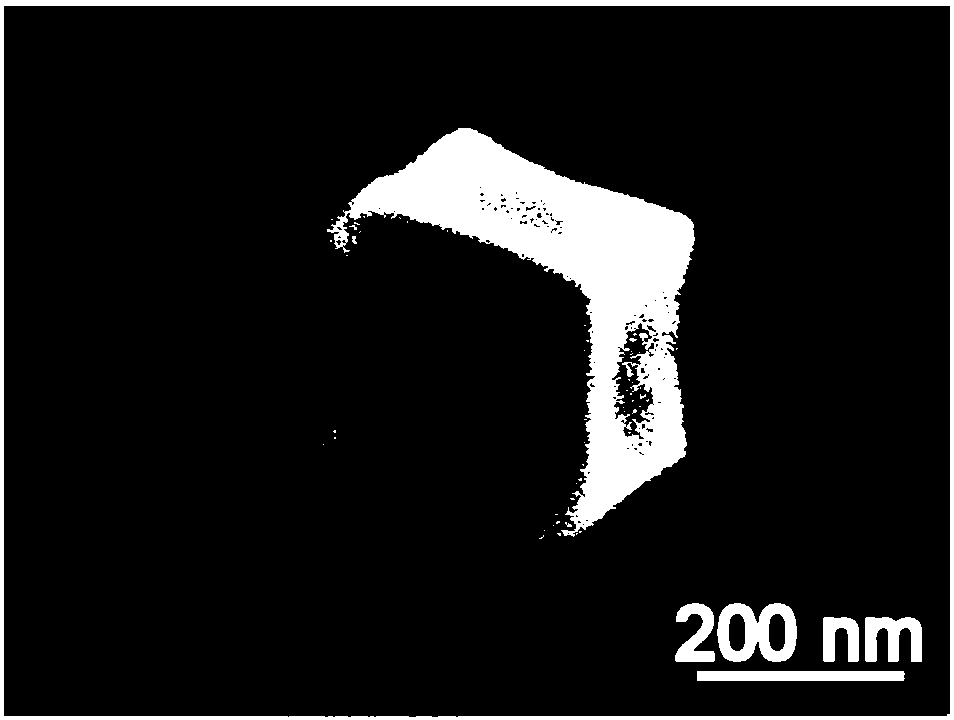

[0033] First, ZIF-67 was prepared by solution precipitation method. 8 mmol 2-methylimidazole and 2 mmol cobalt nitrate hexahydrate were dissolved in 50 ml methanol solution to obtain a clear solution, and then the two solutions were mixed and stirred at room temperature for 24 hours. Subsequently, the reaction product is centrifuged, washed, and dried to obtain solid purple powder ZIF-67, and the morphology picture of ZIF-67 is as follows: figure 1 As shown, it presents a standard rhombic dodecahedron structure. Take 40mg ZIF-67 powder and evenly disperse it in 20ml ethanol solution, add 5ml ferric nitrate ethanol solution (2mg / ml), stir and react for two hours at room temperature, ZIF-67 3+ The etching action of hydrogen ions generated by hydrolysis releases Co 2+ , with the consumption of hydrogen protons, Fe 3+ and Co 2+ Co-precipitate on ZIF-67 particles to obtain iron-modified Fe-ZIF-67, then centrifuge, wash and dry the reaction product to obtain purple solid powder F...

Embodiment 3

[0035] The prepared above-mentioned Fe-CoSe 2 @NC powder material is mixed with conductive carbon black and polyvinylidene fluoride at a mass ratio of 5:4:1, mixed with ethanol to make a slurry and brushed on CFP to make Fe-CoSe 2 @NC / CFP electrode, dried at 50°C for 12 hours. CoSe 2 @NC electrode material is loaded on CFP according to the same ratio and brushing method to prepare CoSe 2 @NC / CFP electrodes. Among them, Fe-CoSe 2 @NC and CoSe 2 The load of @NC active ingredient on CFP is 0.5mg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com