Chemical copper plating liquid applied to zinc oxidepressure sensitive resistor copper electrode and copper plating technique thereof

A varistor, chemical copper plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of poor stability of chemical copper plating solution, not meeting energy saving and environmental protection, coating uniformity, Corrosion resistance, hardness, insufficient weldability, etc., to achieve the effect of excellent weldability, excellent performance, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

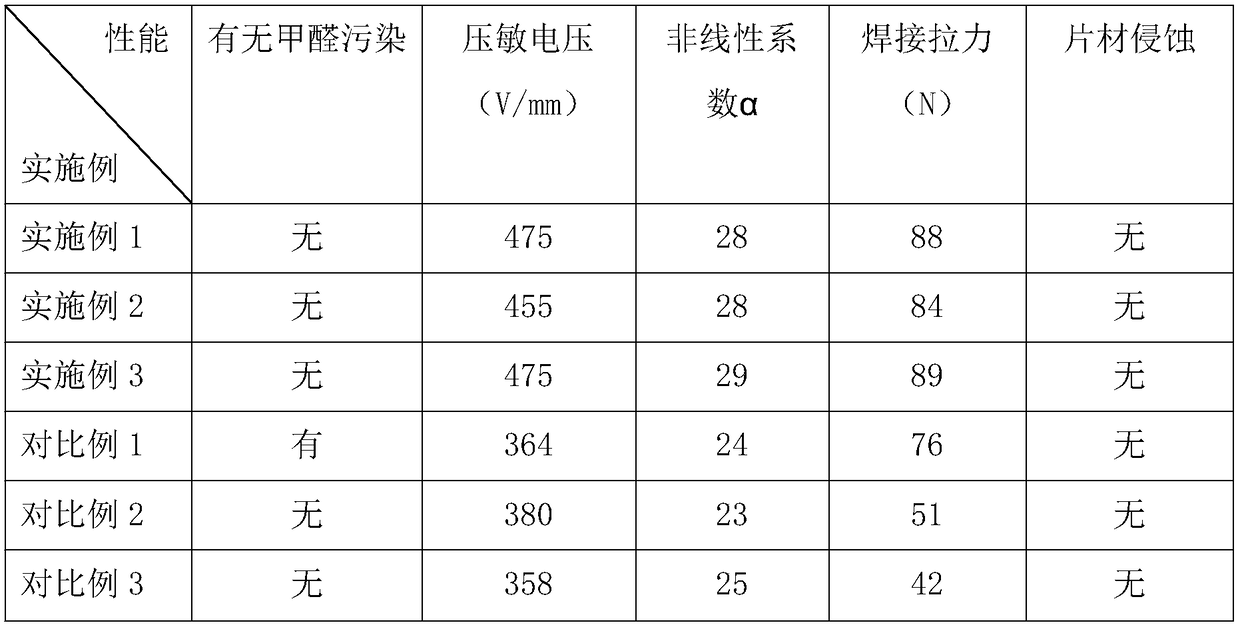

Examples

Embodiment 1

[0018] An electroless copper plating solution applied to copper electrodes of zinc oxide varistors, comprising the following components: copper sulfate 10g / L, EDTA 6g / L, tetrahydroxypropyl ethylenediamine 4g / L, ethylenediaminetetraacetic acid di Sodium 7g / L, sodium hydroxide 70g / L, sodium hypophosphite 4g / L, hydrazine hydrate 10mg / L, 2,2'-bipyridine 90mg / L, surfactant 2g / L, accelerator 2g / L, pH regulator 4g / L and antioxidant 1g / L.

[0019] Described surfactant is stearic acid.

[0020] A copper plating process applied to an electroless copper plating solution for copper electrodes of zinc oxide varistors, comprising the following steps: step 1, carrying out pickling treatment of zinc oxide varistor ceramic substrates successively, followed by deionized water and ethanol Cleaning and drying treatment; step 2, preparing an electroless copper plating solution and ultrasonic treatment to obtain an electroless copper plating dispersion; step 3, at room temperature, putting the zin...

Embodiment 2

[0024] An electroless copper plating solution applied to copper electrodes of zinc oxide varistors, comprising the following components: copper sulfate 15g / L, disodium EDTA 8g / L, tetrahydroxypropyl ethylenediamine 8g / L, ethylenediamine Disodium tetraacetate 11g / L, sodium hydroxide 100g / L, sodium hypophosphite 10g / L, hydrazine hydrate 20mg / L, 2,2'-bipyridine 90-110mg / L, surfactant 6g / L, Agent 8g / L, pH adjuster 8g / L and antioxidant 3g / L.

[0025] The surfactant is sodium dodecylbenzenesulfonate.

[0026] A copper plating process applied to an electroless copper plating solution for copper electrodes of zinc oxide varistors, comprising the following steps: step 1, carrying out pickling treatment of zinc oxide varistor ceramic substrates successively, followed by deionized water and ethanol Cleaning and drying treatment; step 2, preparing an electroless copper plating solution and ultrasonic treatment to obtain an electroless copper plating dispersion; step 3, at room temperature...

Embodiment 3

[0030] An electroless copper plating solution applied to copper electrodes of zinc oxide varistors, comprising the following components: copper sulfate 12g / L, disodium EDTA 7g / L, tetrahydroxypropyl ethylenediamine 7g / L, ethylenediamine Disodium tetraacetate 9g / L, sodium hydroxide 90g / L, sodium hypophosphite 8g / L, hydrazine hydrate 12.8mg / L, 2,2'-bipyridine 112.5mg / L, surfactant 4g / L, Agent 6g / L, pH adjuster 7g / L and antioxidant 2.5g / L.

[0031] The surfactant is fatty acid glyceride.

[0032] A copper plating process applied to an electroless copper plating solution for copper electrodes of zinc oxide varistors, comprising the following steps: step 1, carrying out pickling treatment of zinc oxide varistor ceramic substrates successively, followed by deionized water and ethanol Cleaning and drying treatment; step 2, preparing an electroless copper plating solution and ultrasonic treatment to obtain an electroless copper plating dispersion; step 3, at room temperature, putting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com