Method for preparing hollow beads

A technology of hollow microspheres and agglomerates, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve problems such as high energy consumption and cost, high requirements for production process control, uncontrollable product properties, etc., and achieve high performance Controllable, good weather resistance, high-quality and low-cost products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

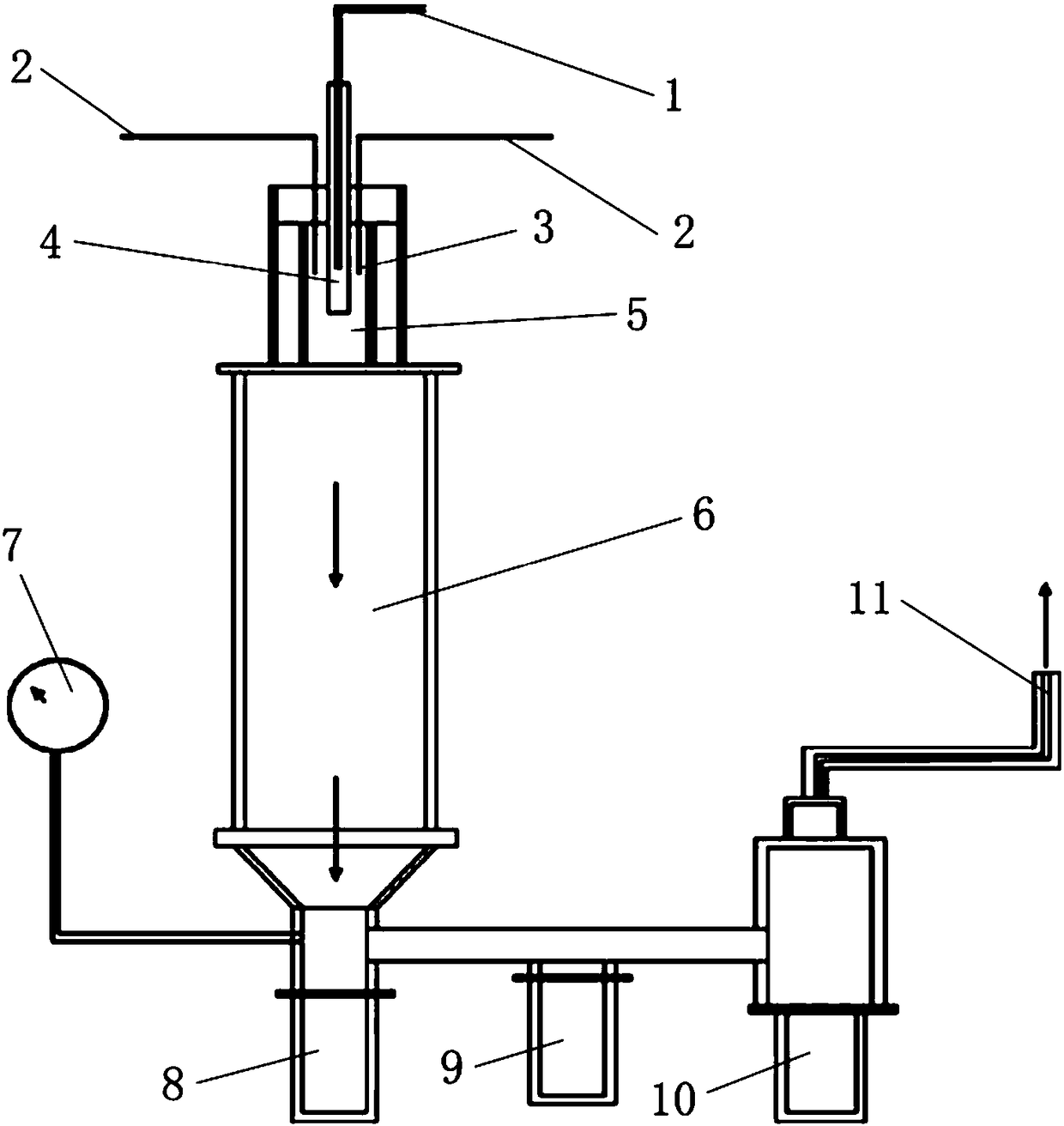

Embodiment 1

[0025] The preparation method of hollow microspheres in this example is to make solid waste, modifying agent, foaming agent and flux into powdery aggregates, and the powdery aggregates are sent into the spray combustion device, and undergo melting, expansion and rapid condensation process, preparing inorganic hollow microsphere materials with different particle sizes and different structures; the powder aggregates are by weight, and the solid waste is: 50% of waste glass, 30% of waste incineration bottom ash, 10% of fly ash bottom ash, Incineration bottom ash of water treatment sludge is 5%, modifier: 1% alumina, magnesia 1%, titanium dioxide 1%, foaming agent: calcium carbonate 1%, flux: lithium oxide 1%.

[0026] The preparation process of powdery agglomerates is as follows:

[0027] The solid waste, modifying agent, foaming agent and fluxing agent are crushed into fine powder with a particle size of 10 μm, and then the mixed fine powder is granulated by spray granulation eq...

Embodiment 2

[0033] In the preparation method of the hollow microspheres of this example, the solid waste is: waste glass 10%, water treatment sludge incineration bottom ash 3%, steel slag 1%, waste activated carbon 1%, modifier is: calcium silicate 10%, Calcium aluminosilicate 20%, tetraethyl orthosilicate 10%, sodium silicate 30%, foaming agent: silicon nitride 5%, fluxing agent: boron oxide 10%.

[0034] Crush solid waste, modifiers, foaming agents and fluxing agents into fine powders with a particle size of 0.1 μm, and then use spray granulation equipment to granulate the mixed fine powders to obtain powder agglomerates with an average particle size of 50 μm .

[0035] The mixture of methane and oxygen is used as the combustible gas, the temperature of the flame is 700°C, and the length of the flame is 0.5m; the powdery agglomerates are sent to the nozzle 4 through the powder inlet 1 at a speed of 1g / s for atomization, and finally, the obtained Hollow microspheres with an average part...

Embodiment 3

[0040] In the preparation method of the hollow microspheres of this example, the solid waste is: 60% of fly ash fly ash, 6% of river and lake bottom mud, 5% of sewage treatment sludge, 10% of steel slag, 10% of waste activated carbon, and the modifying agent is : Potassium silicate 1%, silicic acid 2%, foaming agent: silicon carbide 1%, carbon black 4%, fluxing agent: silicon dioxide 1%.

[0041] All the other are with embodiment two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com