Preparation method of Pt-loaded sulfur-rich molybdenum disulfide boundary site modified titanium dioxide nanotube array

A technology of nanotube array and molybdenum disulfide, which is applied in the field of photocatalytic degradation of pollutant materials, can solve the problems of low utilization rate, low photocatalytic activity, and limited application, and achieve the goals of improved photoelectric performance, simple process, and improved catalytic ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

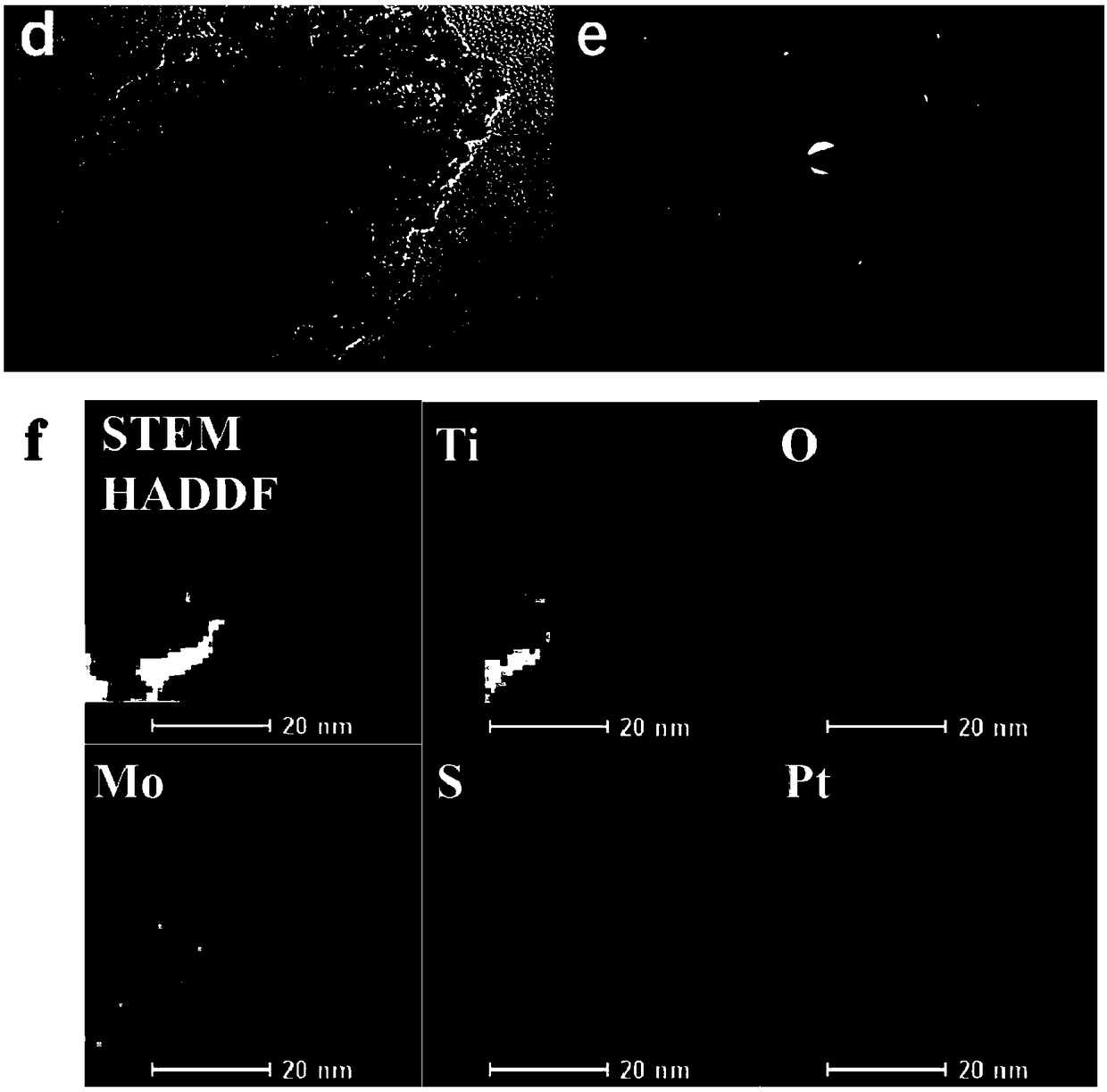

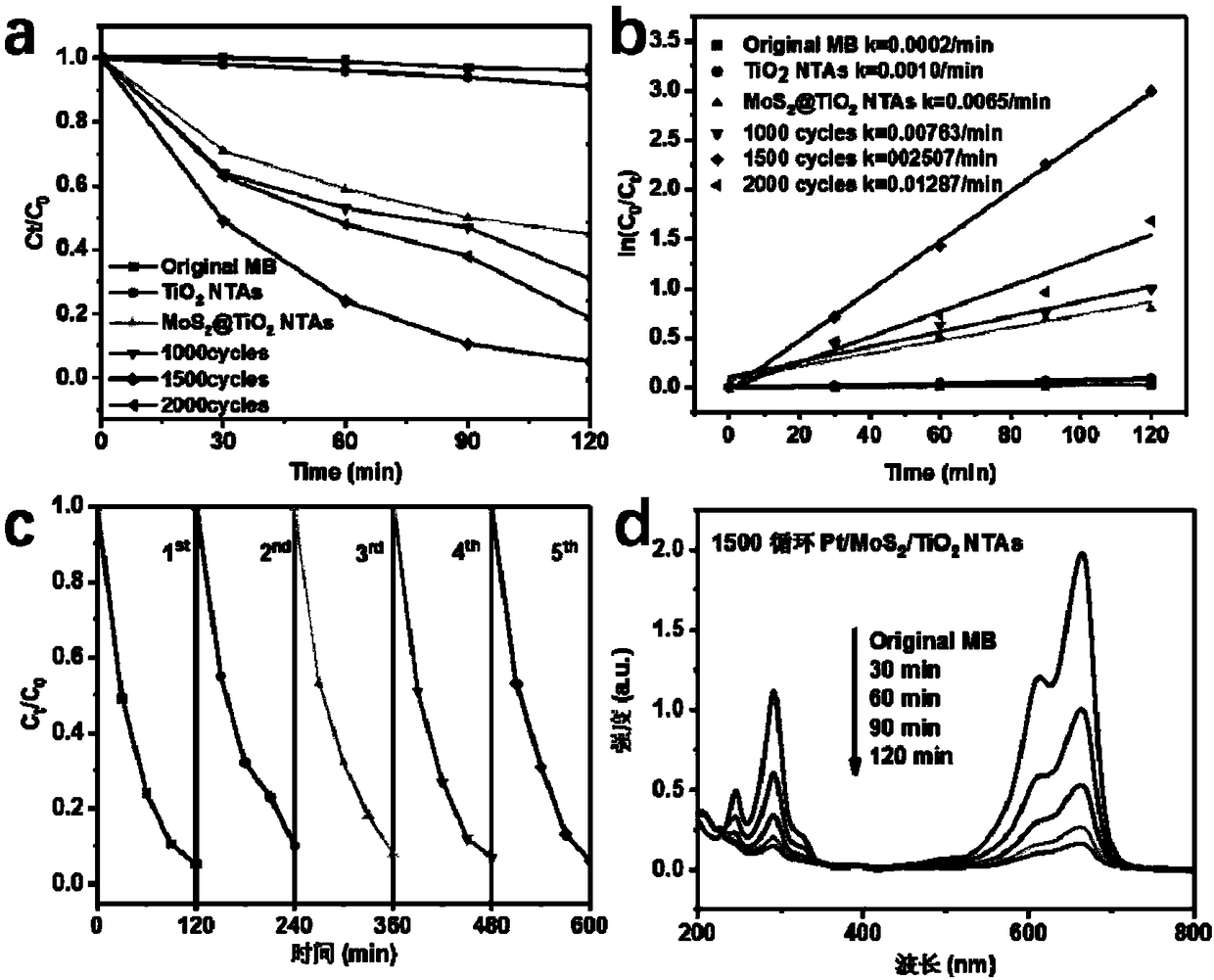

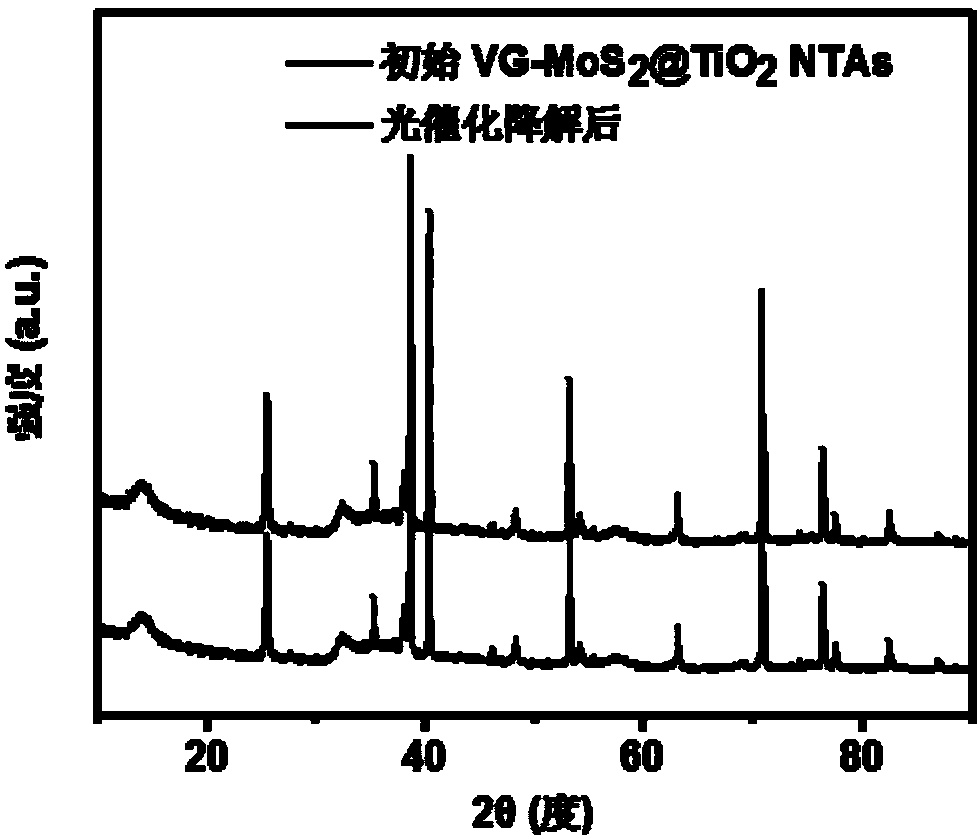

[0033] see figure 1 , figure 1 It is a schematic flow chart of the preparation method of the Pt-loaded sulfur-rich molybdenum disulfide boundary site modified titania nanotube array of the present invention. Such as figure 1 As shown, the present invention provides a method for preparing a Pt-loaded sulfur-rich molybdenum disulfide boundary site modified titanium dioxide nanotube array, comprising the following steps:

[0034] Pretreatment of titanium sheet;

[0035] Preparation of TiO by Anodic Oxidation 2 nanotube arrays;

[0036] Hydrothermal preparation of vertically structured sulfur-rich molybdenum disulfide nanosheets / titanium dioxide nanotube arrays;

[0037] Using the sulfur-rich molybdenum disulfide nanosheet / titanium dioxide nanotube array as a working electrode, the Pt wire as a counter electrode, and sulfuric acid solution as an electrolyte, a Pt-loaded sulfur-rich molybdenum disulfide boundary site modification was prepared by cyclic voltammetry. Titanium ...

Embodiment 1

[0057] This implementation case demonstrates a preparation method of a Pt-supported sulfur-rich molybdenum disulfide boundary site modified titanium dioxide nanotube array according to the following steps:

[0058] (1) Pretreatment of titanium sheet and preparation of TiO by secondary anodic oxidation 2 Nanotube array: The titanium sheet substrate was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 20 minutes in sequence. Using the platinum sheet electrode as the cathode, insert it into the electrolyte solution containing 98v% ethylene glycol (ammonium fluoride 0.5wt%) and 2v% water at the same time, apply a voltage of 50V for anodic oxidation for 1.5h, after ultrasonic peeling off the film layer, continue to apply a voltage of 50V Anodized for 6 minutes to produce TiO 2 The nanotube arrays were then heat-treated at 450°C for 2 hours to transform from an amorphous state to anatase with a better crystal form.

[0059] (2) Using hydrothermal tr...

Embodiment 2

[0063] This implementation case demonstrates a preparation method of a Pt-supported sulfur-rich molybdenum disulfide boundary site modified titanium dioxide nanotube array according to the following steps:

[0064] (1) Pretreatment of titanium sheet and preparation of TiO by secondary anodic oxidation 2 Nanotube array: The titanium sheet substrate was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 20 minutes in sequence. Using the platinum sheet electrode as the cathode, insert it into the electrolyte solution containing 98v% ethylene glycol (ammonium fluoride 0.5wt%) and 2v% water at the same time, apply a voltage of 50V for anodic oxidation for 1.5h, after ultrasonic peeling off the film layer, continue to apply a voltage of 50V Anodized for 6 minutes to produce TiO 2 The nanotube arrays were then heat-treated at 450°C for 2 hours to transform from an amorphous state to anatase with a better crystal form.

[0065] (2) Using hydrothermal tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com