Synthesis and application of nano carbon fiber electrocatalyst containing cobalt-molybdenum oxide

A nano-carbon fiber, electrochemical technology, applied in electrochemical generators, electrodes, circuits, etc., can solve the problems of high cost and high price, and achieve the effects of efficient production, cheap raw materials, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a. Take 5mmol Co(OAc) 2 4H 2 O, 15ml of ethanol and 7mmol of Py were mixed and stirred until the solid was completely dissolved, stirred and added dropwise with 10mmol of CH 3 COOH and 10 mmol H 2 o 2 Mix the solution to obtain a brown solution, add 5ml of water to reflux at 80°C for 1 hour, cool to room temperature, add 20mL of 0.02g / mL sodium perchlorate aqueous solution, place it at 5°C for 48 hours, filter, wash with water, and dry to obtain a brown color Solid, i.e. nitrogen-containing cobalt compound;

[0020] b. Add 1 mmol H to 4 mmol nitrogen-containing cobalt compound in acetonitrile solution 3 PMo 12 o 40 The aqueous solution, the volume ratio of acetonitrile and water is 1:1, stirring and filtering and washing with water and acetonitrile obtains nitrogen-containing cobalt-phosphomolybdic acid ion crystal compound;

[0021] c. Dissolve 100 mg of the nitrogen-containing cobalt-phosphomolybdic acid ion crystal compound obtained in step b in 2 g of DMF, ad...

Embodiment 2

[0023] a. Take 5mmol Co(OAc) 2 4H 2 O and 20mL of ethanol were placed in a flask, and 5mmol of peracetic acid was added dropwise. Stir and observe that the color turns olive green, add 7mmol pyridine, reflux at 80°C for 1 hour, cool to room temperature, add 20mL 0.02g / mL sodium perchlorate solution, place at 5°C for 48 hours, filter, wash with water, and dry Obtain a brown solid that is a nitrogen-containing cobalt compound;

[0024] b. Add 1 mmol H to 4 mmol nitrogen-containing cobalt compound in acetonitrile solution 3 PMo 12 o 40 The aqueous solution, the volume ratio of acetonitrile and water is 1:1, stirring and filtering and washing with water and acetonitrile obtains nitrogen-containing cobalt-phosphomolybdic acid ion crystal compound;

[0025] c. Dissolve 100 mg of the nitrogen-containing cobalt-phosphomolybdic acid ion crystal compound obtained in step b in 2 g of DMF, add 200 mg of PAN, stir until the solution is homogeneous, and form nanofibers by electrospinni...

Embodiment 1

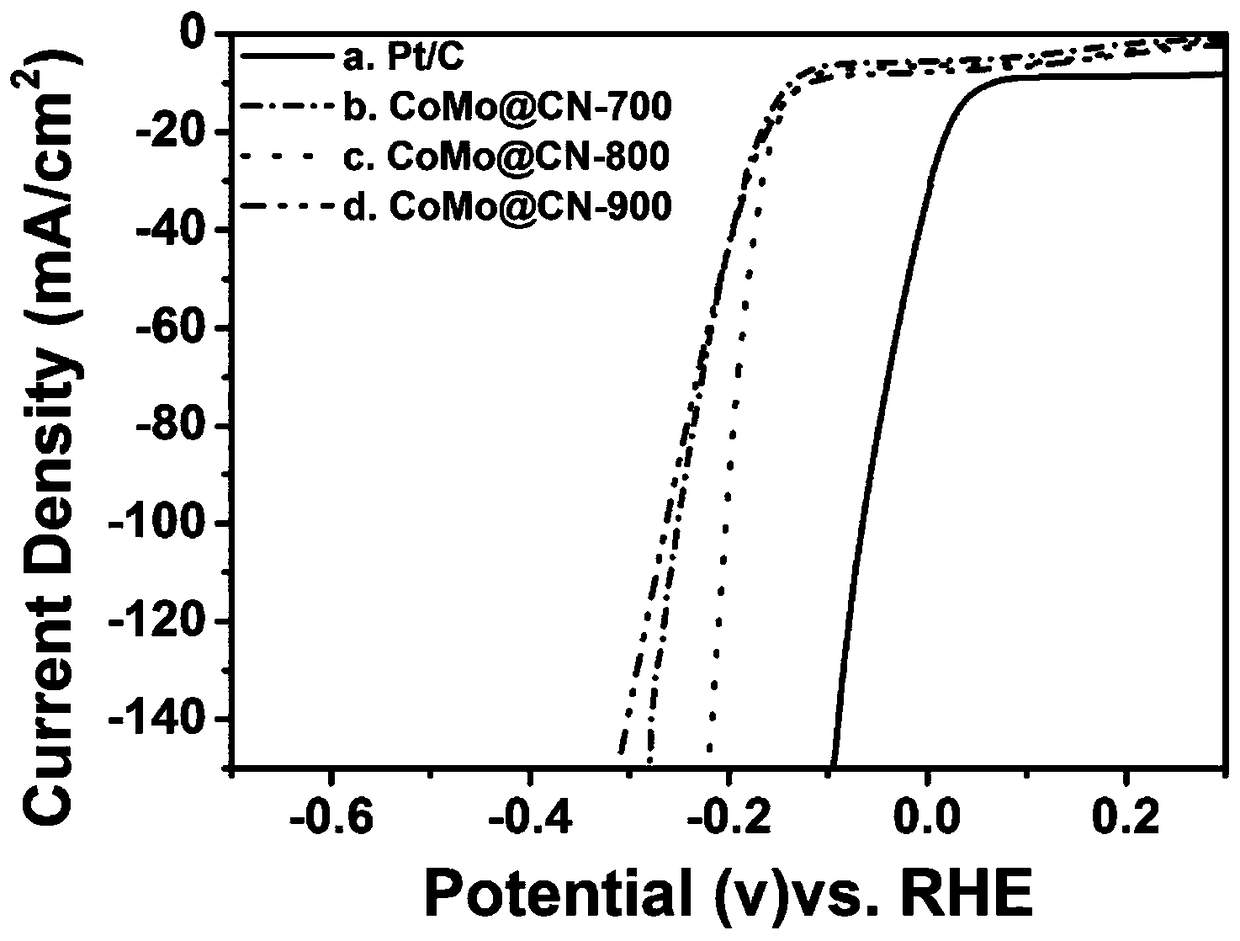

[0027] Weigh 5 mg of the catalyst in Example 1, add 2 mg of alkyne black, 50 μL of Nafion, disperse in 1 ml of ethanol, take 126 μL and add dropwise 1*1cm 2 carbon paper, at 0.5M H 2 SO 4 Tested in solution, the reference electrode is Ag / AgCl electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com