Preparation and application of porous silicon nanowire-cadmium sulfide quantum dot composite photocatalytic material with core-shell structure

A technology of composite photocatalysis and core-shell structure, which is applied in the field of preparation of core-shell structure porous silicon nanowire-cadmium sulfide quantum dot composite photocatalytic materials, can solve the problems of low photocatalytic activity and easy surface oxidation, and achieves photocatalytic performance. The effect of high catalytic activity, high photocatalytic activity and catalytic efficiency, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

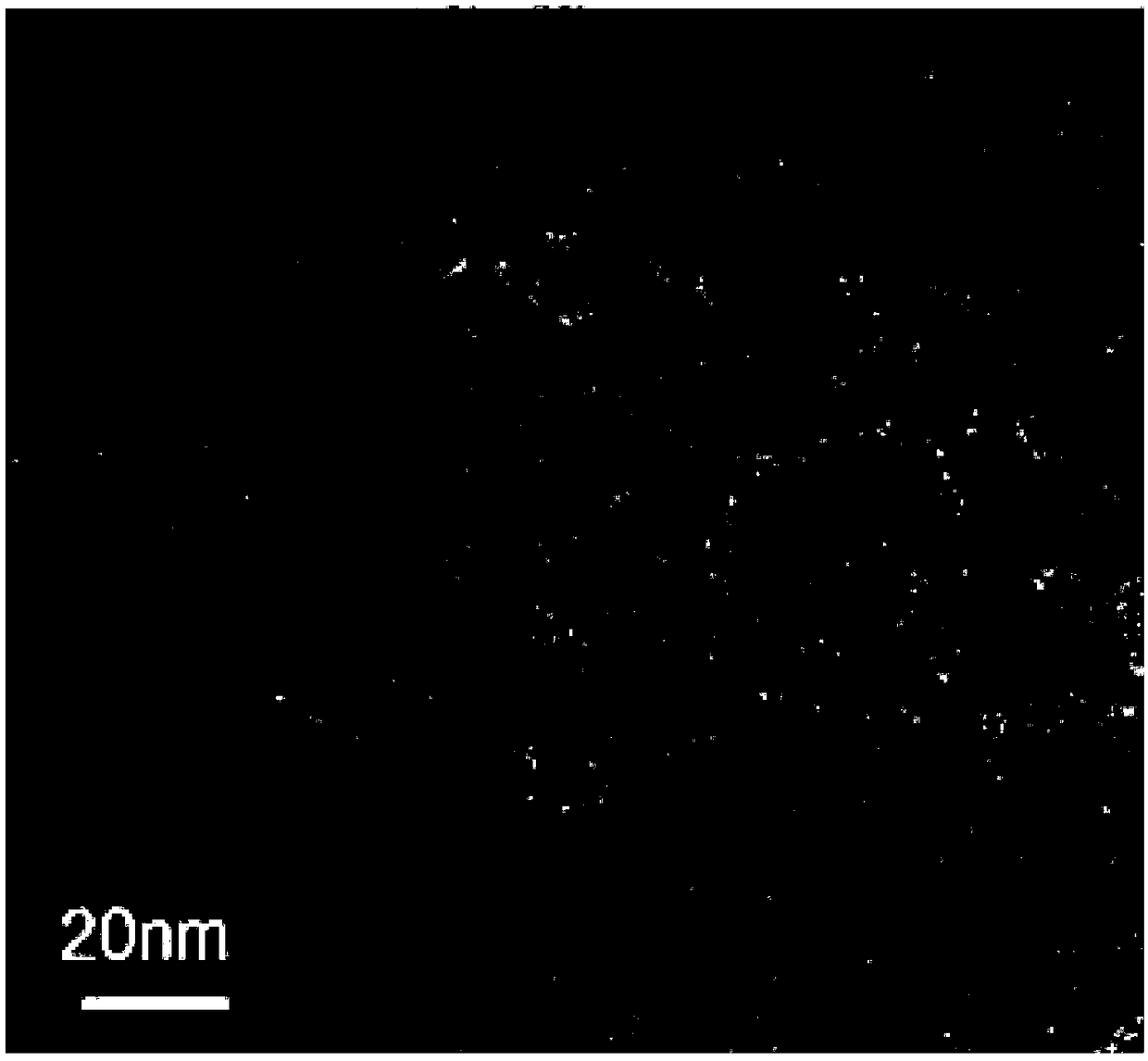

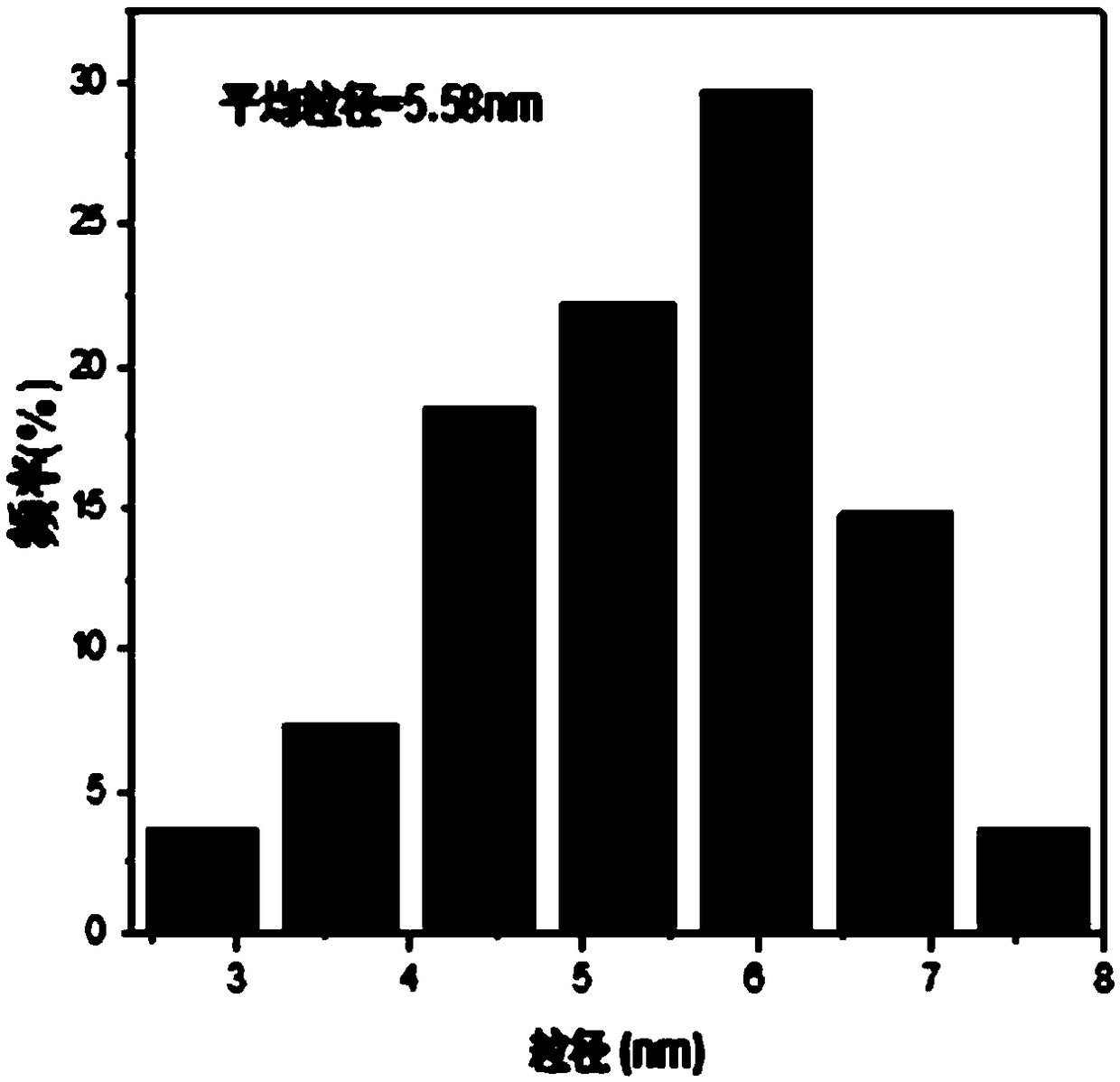

[0038] A method for preparing a core-shell structure porous silicon nanowire-cadmium sulfide quantum dot composite photocatalytic material, comprising the following steps:

[0039](1) After cutting the boron-doped silicon wafer into a specified size, perform ultrasonic impregnation with acetone, ethanol and deionized water in order to remove impurities on the surface of the boron-doped silicon wafer, and then use a volume mixing ratio of 3: After washing the surface with a mixture of concentrated sulfuric acid and hydrogen peroxide in 1, wash it with deionized water, and then soak the boron-doped silicon wafer in a hydrofluoric acid solution with a mass concentration of 5% to remove its surface adhesion. oxide, and then put it into a mixed solution with a concentration of 0.01mol / L silver nitrate and a concentration of 4mol / L hydrofluoric acid and stir to make the surface of the boron-doped silicon wafer adhere to Ag nanoparticles, then take it out and use it After washing wit...

Embodiment 1

[0050] (1) The cut silicon wafer (10mm×20mm×0.3mm) is ultrasonically treated with acetone, ethanol and deionized water in sequence, then soaked in a 3:1 mixed solution of concentrated sulfuric acid and hydrogen peroxide for washing, and then taken out for use Rinse it repeatedly with deionized water, and then soak the cleaned silicon wafer in AgNO 3 (0.01mol / L) and HF (4mol / L)) solution for 1min to make the surface loaded with Ag particles, then put it into deionized water to suck out the excess Ag ions, and then place the silicon wafer deposited with Ag nanoparticles on HF and H 2 o 2 Etching treatment in the mixed solution for 1h, after the treatment, soak it in concentrated HNO 3 In order to remove residual Ag particles, it was taken out and rinsed with deionized water and 5% HF in sequence, and finally dried with nitrogen to obtain nanowires.

[0051] (2) Soak the silicon nanowire sheet in 50mL of deionized water, then add 2mL of BPEI solution (86mg / mL), and pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com