Porous gold-modified interdigital electrode as well as preparation method and application thereof

An interdigital electrode and surface modification technology, applied in the field of porous gold-modified interdigital electrodes and their preparation, can solve problems such as large noise and errors, skin allergic reactions, redness and swelling, and achieve increased active surface area, increased sensitivity, high The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Nanoporous gold-modified interdigitated electrodes:

[0039] (1) Soak the surface of the commercialized interdigitated electrode with 1%wt citric acid solution for 10 minutes, clean it with deionized water and set aside;

[0040] (2) Immerse the surface-treated interdigital electrode into gold citrate 10g / L, stannous sulfate 20g / L, ascorbic acid 10g / L, potassium sulfate 20g / L, dipotassium hydrogen phosphate 20g / L, and the pH value is at 4- 6, the temperature is between 45-55°C, the current density is 1.0-1.5ASF, the electrodeposition time is 5min, and then the gold-tin alloy coating is obtained.

[0041] (3) The obtained gold-tin-containing interdigitated electrode sample was immersed in 10 mol / L potassium hydroxide and 5 mol / L hydrogen peroxide for 3 hours to obtain a nanoporous gold-modified interdigitated electrode.

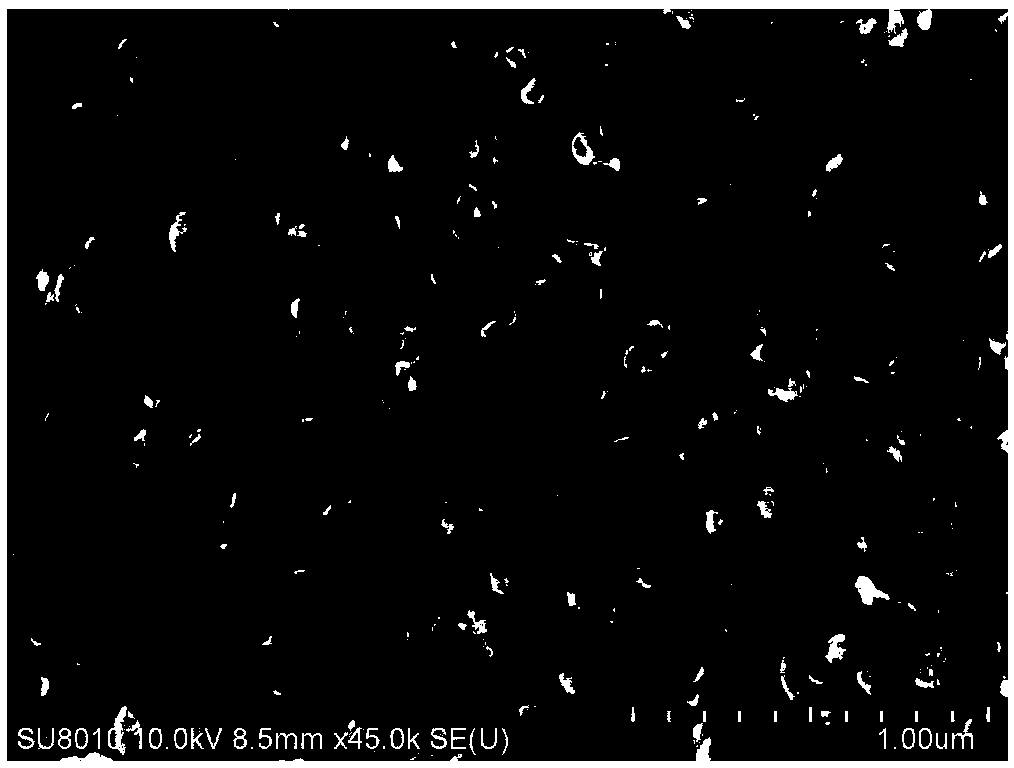

[0042] attached figure 1 It is the scanning electron microscope picture of the interdigitated electrode modified by nanoporous gold in Example 1 at 1...

Embodiment 2

[0044] Nanoporous gold-modified interdigitated electrodes:

[0045] (1) Soak the surface of the commercialized interdigitated electrode with 1.5%wt citric acid solution for 10 minutes, then clean it with deionized water and set aside;

[0046] (2) Immerse the surface-treated interdigital electrode into 20g / L of gold citrate, 20g / L of stannous sulfate, 10g / L of ascorbic acid, 20g / L of potassium sulfate, 20g / L of dipotassium hydrogen phosphate, and the pH value is about 5 , the temperature is between 45-55°C, the current density is 2.0-2.5ASF, the electrodeposition time is 5min, and then the gold-tin alloy coating is obtained.

[0047](3) The obtained gold-tin-containing interdigitated electrode sample was immersed in 5 mol / L potassium hydroxide and 10 mol / L hydrogen peroxide for 3 hours to obtain a nanoporous gold-modified interdigitated electrode.

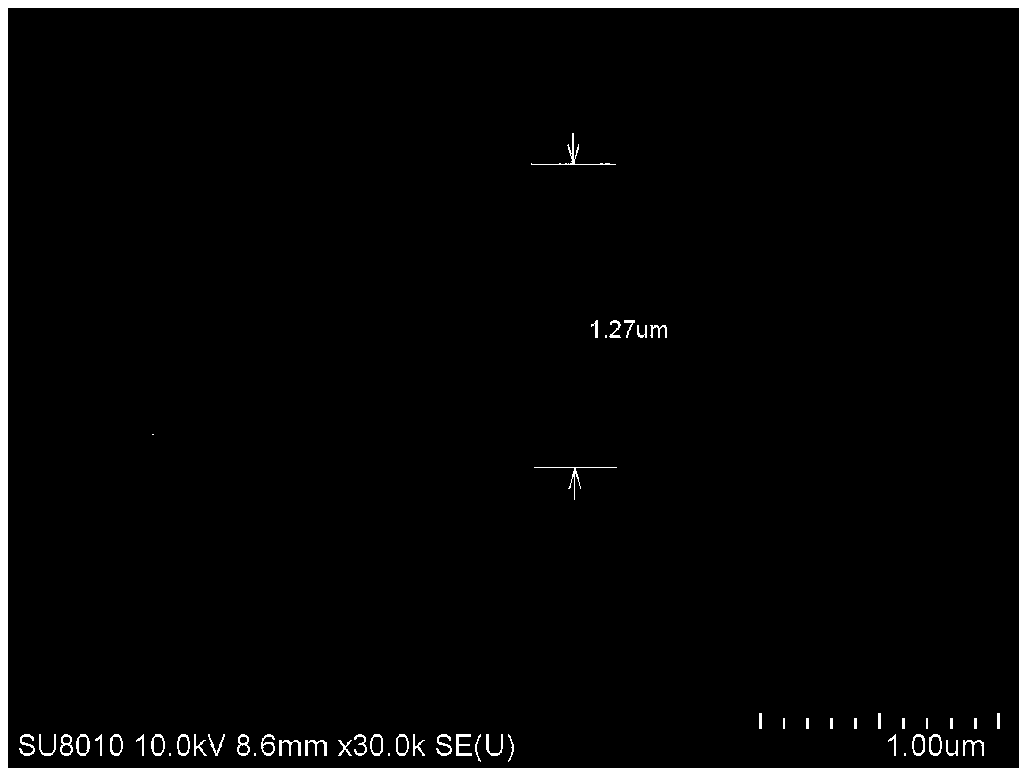

[0048] attached figure 2 It is the scanning electron microscope picture of the interdigitated electrode modified by nanoporous...

Embodiment 3

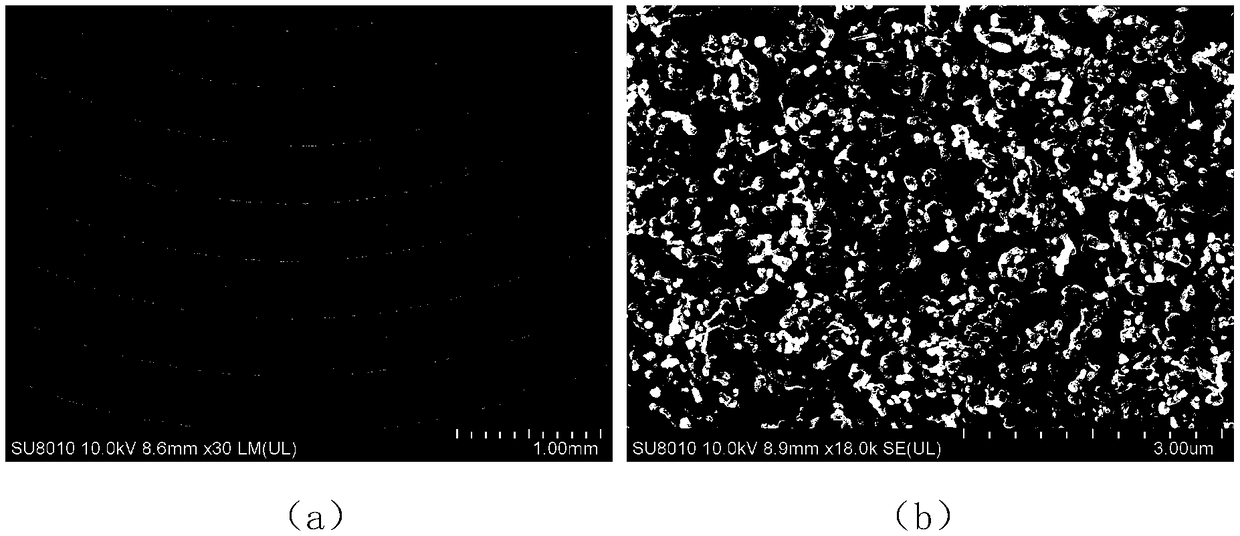

[0050] Mass production of nanoporous gold-modified interdigitated electrodes:

[0051] (1) Magnetron sputtering Ti / Pt / Au on the alumina ceramic plate to form a ceramic substrate whose outer surface is gold, and the thickness of each sputtered layer is

[0052] (2) A suspension coating photoresist is used, and the thickness of the photoresist is 2 μm.

[0053] (3) Develop and expose under a photolithography machine to form interdigital electrode patterns.

[0054] (4) In potassium carbonate solution, the photoresist is developed.

[0055] (5) electroplating with glue or soaking in citric acid solution to form gold-tin alloy by electroplating, the solution is composed of gold citrate 8g / L, tin methanesulfonate 10g / L, ascorbic acid 10g / L, potassium sulfate 20g / L, Dipotassium hydrogen phosphate is 20g / L, the pH value is between 4-6, the temperature is between 45-55°C, the current density is 1.0-1.5ASF, and the electrodeposition time is 5min.

[0056] (6) Remove the photoresis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com