Lead sulfide cadmium sediment treatment method

A technology of lead cadmium sulfide and treatment method, which is applied in chemical instruments and methods, lead halide, sulfur compounds, etc., can solve the problems of high energy consumption, unfavorable reuse of sulfate, and limited use of cobalt and nickel smelting. The effect of uniform distribution, high added value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

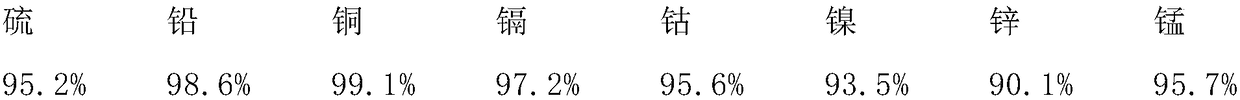

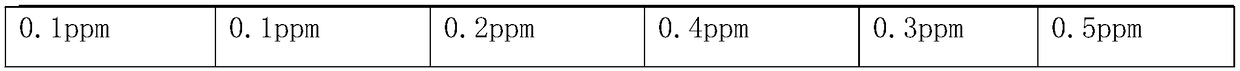

Embodiment 1

[0039] A processing method for lead cadmium sulfide slag, which comprises the following steps:

[0040] (1) Add lead and cadmium sulfide slag to hydrochloric acid solution to slurry, then put it into a high-pressure reactor, feed sulfur dioxide gas, react at a temperature of 155°C and a pressure of 3 atmospheres for 1.5h, and then cool to 39 ℃ to get the cooling material, and the gas released from the pressure release is absorbed by lye;

[0041] (2) Carbon tetrachloride is added to the cooling material, stirred for 0.8h, and the stirring speed is 195r / min, then stratified, the organic layer of the upper floor is extracted, and then the water phase is poured out, and the organic phase is through distillation under reduced pressure Carbon tetrachloride is recovered and returned to use to obtain elemental sulfur;

[0042] (3) Cool the water phase poured out in step (2) to a temperature of 2° C., and then perform solid-liquid separation to obtain the first filtrate and the first...

Embodiment 2

[0066] A processing method for lead cadmium sulfide slag, which comprises the following steps:

[0067] (1) Add lead and cadmium sulfide slag to hydrochloric acid solution to slurry, then put it into a high-pressure reactor, pass in sulfur dioxide gas, react at a temperature of 145°C and a pressure of 3 atmospheres for 1.5h, and then cool to 39 ℃ to get the cooling material, and the gas released from the pressure release is absorbed by lye;

[0068] (2) Carbon tetrachloride is added to the coolant, stirred for 0.8h, and the stirring speed is 230r / min, then stratified, the upper organic layer is extracted, and then the water phase is poured out, and the organic phase is through distillation under reduced pressure Carbon tetrachloride is recovered and returned to use to obtain elemental sulfur;

[0069] (3) Cool the water phase poured out in step (2) to a temperature of 3° C., and then perform solid-liquid separation to obtain the first filtrate and the first filter residue. Ad...

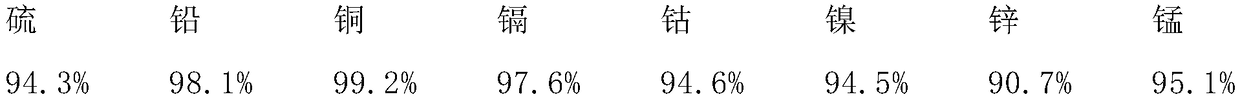

Embodiment 3

[0094] A processing method for lead cadmium sulfide slag, which comprises the following steps:

[0095] (1) Add lead and cadmium sulfide slag to hydrochloric acid solution to slurry, then put it into a high-pressure reactor, pass in sulfur dioxide gas, react at a temperature of 135°C and a pressure of 3 atmospheres for 1.5h, and then cool to 39°C after releasing the pressure. ℃ to get the cooling material, and the gas released from the pressure release is absorbed by lye;

[0096] (2) Carbon tetrachloride is added to the cooling material, stirred for 0.8h, and the stirring speed is 190r / min, then stratified, the organic layer on the upper floor is extracted, and then the water phase is poured out, and the organic phase is distilled under reduced pressure Carbon tetrachloride is recovered and returned to use to obtain elemental sulfur;

[0097] (3) Cool the water phase poured out in step (2) to a temperature of 3° C., and then perform solid-liquid separation to obtain the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com