Preparation method and application of modified electrode based on nanoporous platinum-cobalt oxide hybrid material

A nanoporous, modified electrode technology, applied in the direction of material electrochemical variables, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problem of reducing electrocatalytic activity and specific surface area, and easy agglomeration of platinum nanoparticles , Increase the cost of nitrite, etc., to achieve the effect of low cost, low detection limit, and prevention of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Preparation of nanoporous platinum-cobalt oxide composite material

[0044] Melt pure aluminum, cobalt, platinum (85:14:1) at high temperature to form an alloy, and use cold rolling technology to make it into thin sheets during the cooling process; take 100mg of the alloy and corrode the aluminum in 0.1M sodium hydroxide solution, and use ultra-pure Washing with water until the cleaning solution is neutral, the nanoporous platinum-cobalt oxide composite material can be obtained, which is dried for use.

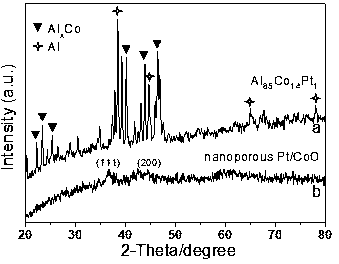

[0045] X-ray diffraction pattern (XRD) of the prepared nanoporous platinum-cobalt oxide composite ( figure 1 Middle a curve) shows that before dealloying, many diffraction peaks can be observed, which are attributed to metallic aluminum and Al x The face-centered cubic structure of the Co phase. During dealloying, aluminum is corroded by sodium hydroxide, while the more active cobalt is oxidized to cobalt oxide, which stabilizes each other with platinum....

Embodiment 2

[0046] Example 2: Preparation of Nanoporous Platinum-Cobalt Oxide Composite Modified Electrode

[0047] (1) Polishing and cleaning of glassy carbon electrodes

[0048] Rinse the glassy carbon electrode twice with ultrapure water, and then polish it with 0.5 μm and 0.05 μm alumina slurry for five minutes respectively, rinse off the slurry on the surface of the electrode with ultrapure water, and place it in ultrapure water for one minute. Rinse with ultrapure water and dry for later use.

[0049] (2) Electrode modification

[0050] Grind the dried nanomaterials to a uniform and fine powder, take 4mg of nanomaterial powder, 4mg of carbon powder, 300 μL of ethanol and 100 μL of Nafion solution for ultrasonic mixing until a uniform ink-like suspension is obtained. Take 3 μL of the suspension and apply it on the surface of the glassy carbon electrode, turn a beaker upside down, and let it dry until a uniform film is formed.

Embodiment 3

[0051] Embodiment 3: Modified electrode is used for the cyclic voltammetry scanning of sodium nitrite detection

[0052] (1) Preparation of sodium nitrite standard solution

[0053] Weigh 0.0138g of sodium nitrite powder and add 20mL of phosphate buffer (0.1M, pH=6.0) to dissolve to obtain a 0.01M sodium nitrite solution. Sodium nitrite solutions of other concentrations were prepared in this way.

[0054] (2) Cyclic voltammetry detection of sodium nitrite by modified electrode

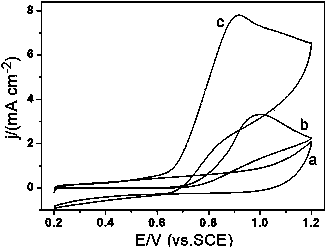

[0055] attached image 3 The cyclic voltammograms (curve a) of the modified electrode in blank phosphate buffer (0.1M, pH6.0), the bare glassy carbon electrode (curve b) and the modified electrode (curve c) in a 0.01M sub- Cyclic voltammogram of sodium nitrate in phosphate buffer. The oxidation peak current of sodium nitrite on the modified electrode is much higher than that on the bare glassy carbon electrode, and the oxidation peak potential has shifted negatively, indicating that the modified na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com