Electromagnetic shielding material, preparation method thereof and cable protection tube produced by electromagnetic shielding material

An electromagnetic shielding material and cable protection tube technology, applied in the field of cable protection tubes, can solve problems affecting the accuracy of aviation flight safety medical equipment, interference with the normal function of electronic devices, and affecting the normal operation of instruments, so as to promote charring reaction and absorption Excellent electromagnetic wave performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

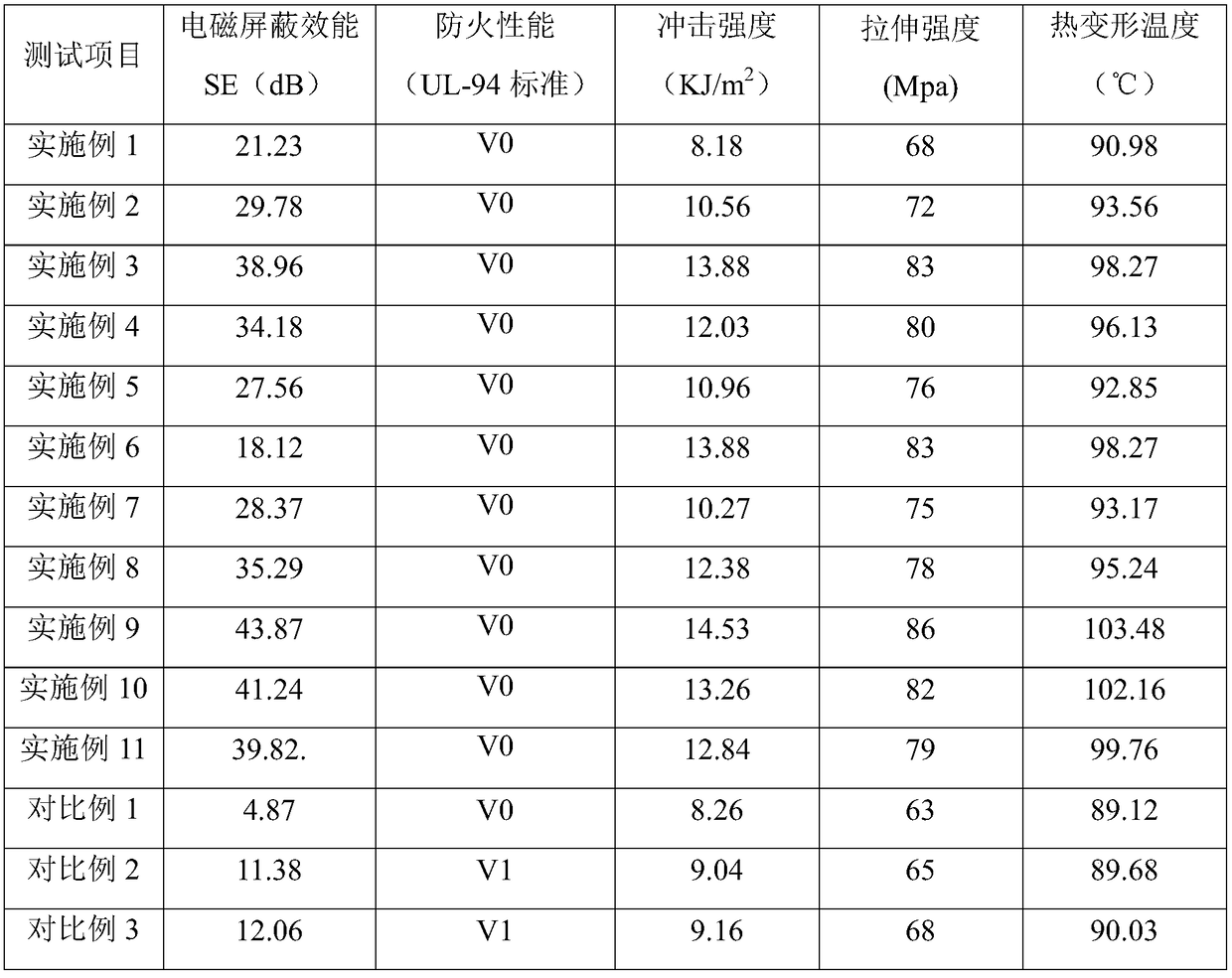

Examples

Embodiment 1

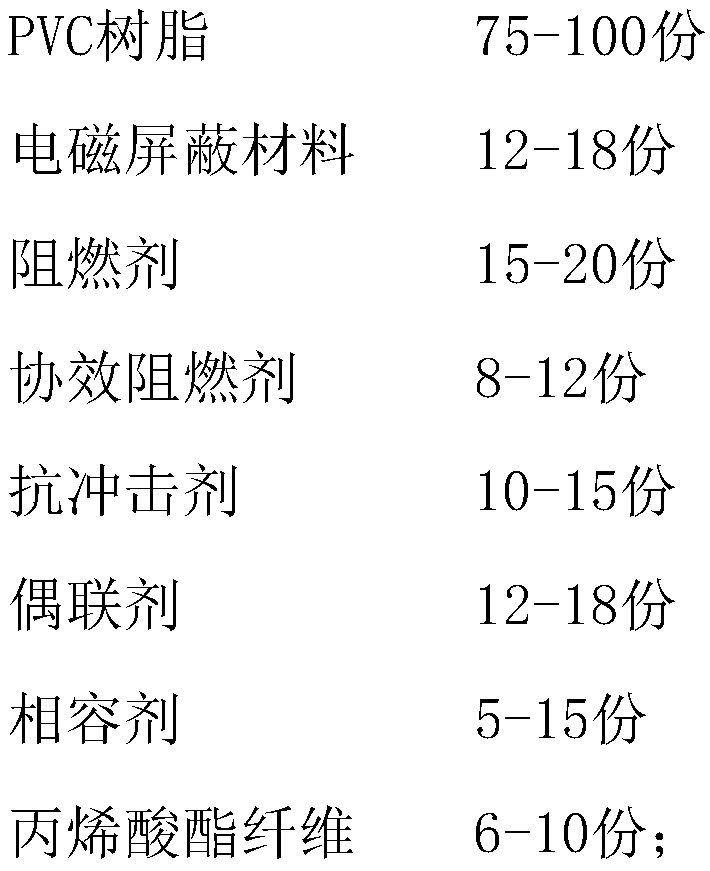

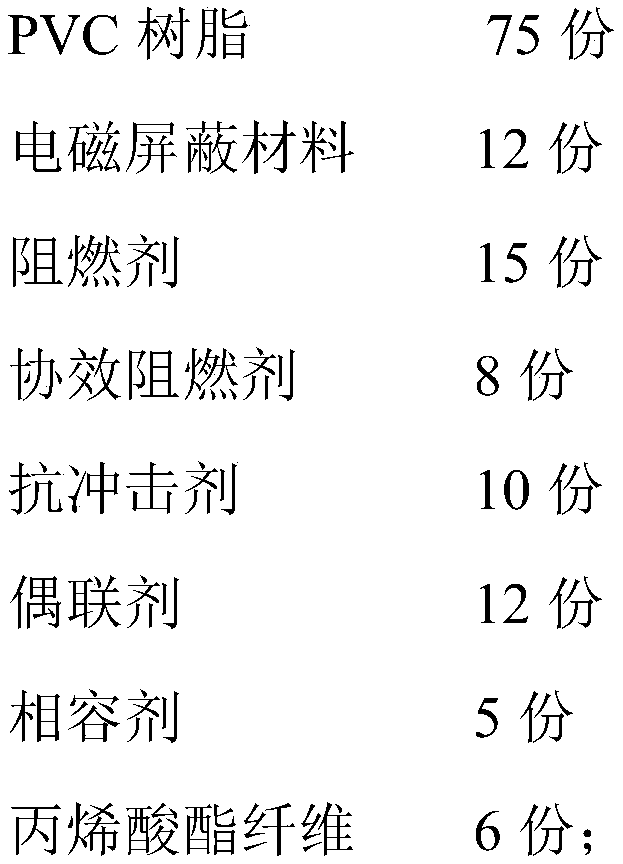

[0049]An electromagnetic shielding material, comprising the following raw materials in parts by weight:

[0050]

[0051] The electromagnetic shielding material is polyaniline-graphene oxide composite material.

[0052] The flame retardant is tetrabromophthalic anhydride; the synergistic flame retardant is zinc stearate.

[0053] The anti-impact agent is methyl methacrylate-butadiene-styrene copolymer.

[0054] The coupling agent is vinyl triethoxysilane; the compatibilizer is hydrogenated styrene-butadiene-styrene copolymer grafted with glycidyl methacrylate.

[0055] Described polyaniline-graphene oxide composite material is made by following steps:

[0056] Step (1): Take 1 part of graphene oxide aqueous solution with a mass fraction of 10% and add it to 45 parts of deionized water, then add 50 parts of stabilizer, and carry out ultrasonic stirring to prepare mixture A;

[0057] Step (2): Take 1 part of protonic acid and 2 parts of aniline monomer and mix evenly, then...

Embodiment 2

[0067] An electromagnetic shielding material, comprising the following raw materials in parts by weight:

[0068]

[0069]

[0070] The electromagnetic shielding material is polyaniline-graphene oxide composite material.

[0071] The flame retardant is tetrabromobisphenol A or 2,4,6-tribromophenol; the synergistic flame retardant is zinc oxide.

[0072] The anti-impact agent is chlorinated polyethylene.

[0073] The coupling agent is anilinomethyltriethoxysilane; the compatibilizer is ethylene-acrylic acid-methyl ester grafted glycidyl methacrylate.

[0074] Described polyaniline-graphene oxide composite material is made by following steps:

[0075] Step (1): Take 1.5 parts of graphene oxide aqueous solution with a mass fraction of 8% and add it to 48 parts of deionized water, then add 52 parts of stabilizer, and carry out ultrasonic stirring to prepare mixture A;

[0076] Step (2): Mix 1.5 parts of protonic acid and 3 parts of aniline monomer evenly, then add to the ...

Embodiment 3

[0086] An electromagnetic shielding material, comprising the following raw materials in parts by weight:

[0087]

[0088] The electromagnetic shielding material is polyaniline-graphene oxide composite material.

[0089] The flame retardant is decabromodiphenyl ether; the synergistic flame retardant is antimony trioxide.

[0090] The anti-impact agent is styrene-butadiene-styrene copolymer.

[0091] The coupling agent is γ-methacryloxypropyltrimethoxysilane or methyltriethoxysilane; the compatibilizer is hydrogenated styrene-butadiene-styrene copolymer grafted methyl Glycidyl acrylate.

[0092] Described polyaniline-graphene oxide composite material is made by following steps:

[0093] Step (1): Take 2 parts of graphene oxide aqueous solution with a mass fraction of 6% and add it to 50 parts of deionized water, then add 55 parts of stabilizer, and carry out ultrasonic stirring to prepare mixture A;

[0094] Step (2): Take 2 parts of protonic acid and 3 parts of aniline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com