Ultra-insulation polyurethane energy-saving plate

An energy-saving board, polyurethane technology, used in thermal insulation, building components, coatings, etc., can solve the problems of loss of thermal insulation performance, weak thermal insulation performance, low hardness, etc., to achieve fast and simple installation, prevent heat radiation, and reduce auxiliary materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

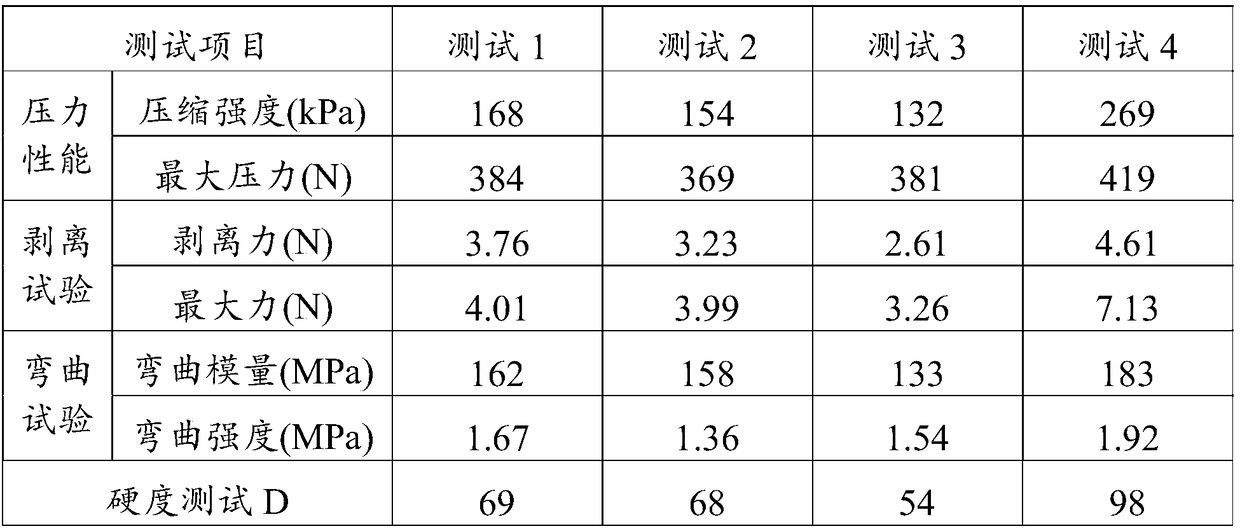

Embodiment 1

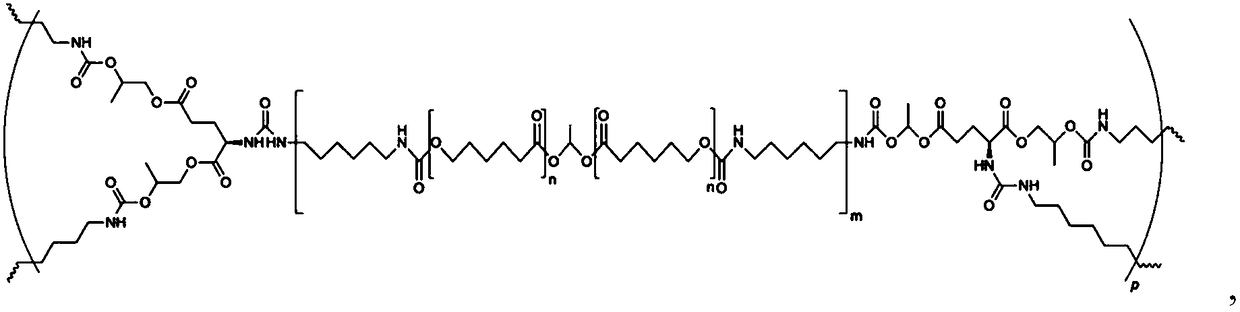

[0022] Synthesize novel polyurethane material, synthetic method is as follows:

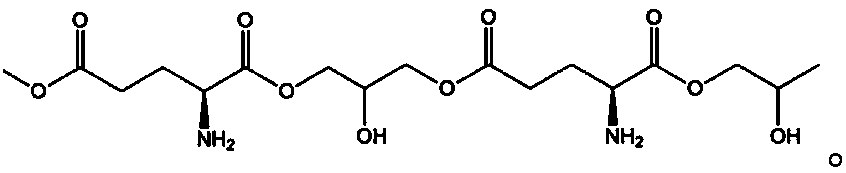

[0023] Step 1: Synthesize by Fischer esterification method, specifically, add 2.74mL, 37.5mmol, 5 equivalents of thionyl chloride to 50ml 1,2-propanediol, react at 0°C for 20 minutes; add 20mmol L -Gln, placed in a magnetic stirrer at room temperature and stirred for 178 hours, the product was taken for thin layer chromatography, verification showed that the amino acid was completely absorbed, and a new chain compound UPAT was obtained, the structural formula is

[0024] Step 2, take a round bottom flask, dissolve 5.6g polycaprolactone diol (2.5mmol, 1.0 equivalent) and 0.74mL 1,6-hexamethylene diisocyanate (20.0mmol, 2.0 equivalent) in 50ml of anhydrous dimethyl The prepolymer is prepared in acetamide, and the reaction is carried out under high-purity nitrogen; the prepolymerization reaction condition is 85° C. for 3 hours, and the catalyst is 0.12 wt % stannous octoate.

[0025] Step 3. Add 0...

Embodiment 2

[0029] Synthesis of high-strength polyurethane containing graphene, the synthesis method is as follows:

[0030] Steps 1 to 2 are as described in Example 1, and in step 3, graphene oxide solution (GO) needs to be added to the prepolymer. The preparation method of graphene oxide solution is as follows: with reference to the method of Hummers, natural graphite is dispersed in sulfuric acid and dissolves with sodium nitrate solution, then adds potassium permanganate wherein, after standing for 12 hours, solution is mixed with hydrogen peroxide Potassium permanganate was removed, placed in a centrifuge to dissociate the solution and form distilled water and graphene oxide, and finally the graphene oxide was cleaned, and the pH level was adjusted to 6.5 to obtain a GO solution.

[0031] Put 5% GO solution and 0.5g UPAT (5mmol, 1.0 equivalent) into the prepolymer, react at 105°C for 2 hours, keep stirring during the reaction, then reduce the reaction temperature to 25°C and overnigh...

Embodiment 3

[0033] A kind of super thermal insulation polyurethane energy-saving board, the thermal insulation energy-saving board includes an anti-corrosion layer; the lower part of the anti-corrosion layer is provided with a first thermal insulation layer; the lower part of the first thermal insulation layer is provided with a first flame-retardant layer; the flame-retardant The lower part of the layer is provided with a second thermal insulation layer; the lower part of the second thermal insulation layer is provided with a second flame retardant layer; the lower part of the second flame retardant layer is provided with an adhesive layer; High temperature adhesive bonding.

[0034] Further, the first insulation layer and the second insulation layer are made of new polyurethane material.

[0035] Further, the thickness of the anti-corrosion layer is 1 mm, prepared by anti-corrosion paint, the thickness of the first heat preservation layer is 5 mm, the thickness of the first flame retard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com