Comprehensive recovery method of material with high chlorine and low zinc

A recycling method and material technology, applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of high production cost, impact on zinc recovery, low zinc recovery rate, etc., achieve low energy consumption in oxidation roasting, and be easy to return to use , fast oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

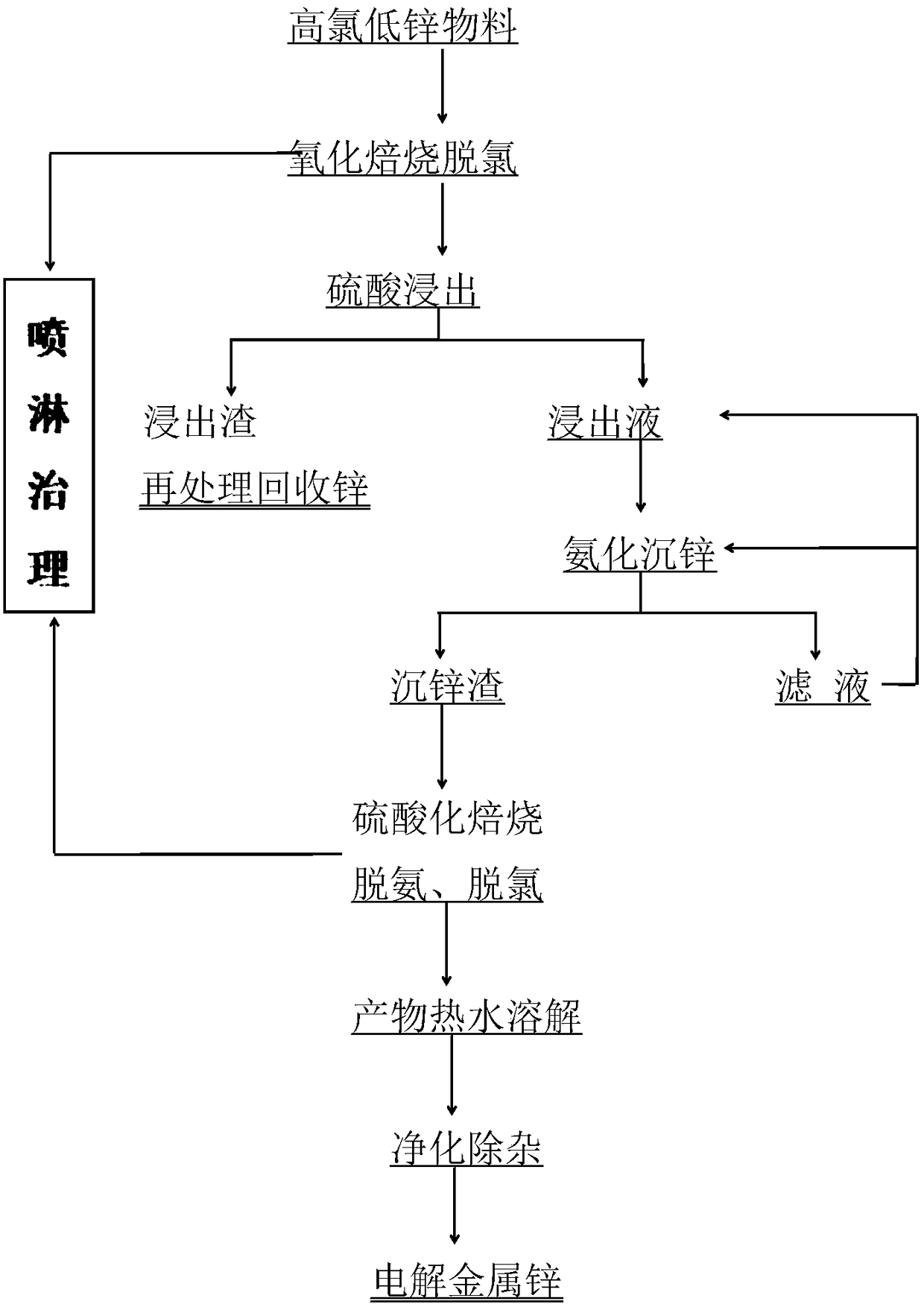

Method used

Image

Examples

Embodiment 1

[0032] The zinc ash produced by a zinc alloy production enterprise after being fried with ammonium chloride contains 25.6% Zn, 10.3% Cl, and 1.2% Al. Metal zinc is recovered by the following steps:

[0033](1) Zinc ash is granulated and added to the rotary kiln for oxidation and roasting. The oxidant is oxygen-enriched air with an oxygen content of 30%, and the air flow rate is 25-30m 3 / min, the calcination temperature is 650°C, the calcination time is 1.5h, and the calcination product containing Zn 38.1%, Cl 1.5%, Al 1.8% is obtained;

[0034] (2) The roasted product is leached by dilute sulfuric acid, and the leaching condition is H 2 SO 4 The concentration is 80g / L, liquid / solid=4, the leaching temperature is 85-90°C, the stirring time is 2.5h, the pH of the leaching end point is 2.5, and the obtained leachate contains 42.5g / L Zn, 1.2g / L Cl, and 0.85g / L Al ;

[0035] (3) Adding ammonium sulfate to the sulfuric acid leaching solution to salt out and crystallize ZnSO 4 ·...

Embodiment 2

[0039] Use the zinc ash produced by electric zinc melting and casting, and the material after fully frying with ammonium chloride and sieving the metal zinc is used as the raw material. The composition of the chlorine-containing zinc ash is Zn 31.4%, Cl 12.1%, and the metal zinc is recovered through the following steps:

[0040] (1) Zinc ash is added to the rotary kiln for oxidative roasting after granulation, and stirred with hydrogen peroxide, manganese dioxide and zinc ash respectively, and the dosage is theoretically oxidized Cl - 1.2 times of that, the roasting temperature is 600°C, and the roasting time is 1.5h, and roasted products containing Zn38.4%, Cl0.85% and Zn30.6%, Cl0.72% are respectively obtained;

[0041] (2) The roasted product containing Zn38.4%, Cl0.85% is leached with dilute sulfuric acid, and the leaching condition is H 2 SO 4 The concentration is 100g / L, liquid / solid=5, the leaching temperature is 85-90°C, the stirring time is 2h, the pH of the leaching...

Embodiment 3

[0046] A low-grade zinc oxide ore containing chlorine and sulfur contains 10.5% zinc, 1.6% chlorine, and 4.1% sulfur. Drum into the amount of 25-30m 3 / min, the temperature is 800 DEG C, roasting 2h, the roasted product contains zinc 15.5%, Cl 0.13%, S 0.016%, carry out dilute sulfuric acid leaching, ammonium sulfate salt precipitation crystallization, sulfation roasting, hot water then according to the condition of embodiment 1 Dissolving and purifying zinc powder, the obtained zinc sulfate solution contains Zn91.4g / L, Cl87mg / L, and the quality of electrolytic zinc is 0# zinc (Zn≧99.995%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com