An enzyme biofuel cell for generating electricity from trehalose produced by Escherichia coli in sewage

A biofuel cell and Escherichia coli technology, which is applied in biochemical fuel cells, battery electrodes, circuits, etc., achieves good application prospects, improves enzyme loading and activity, and has simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

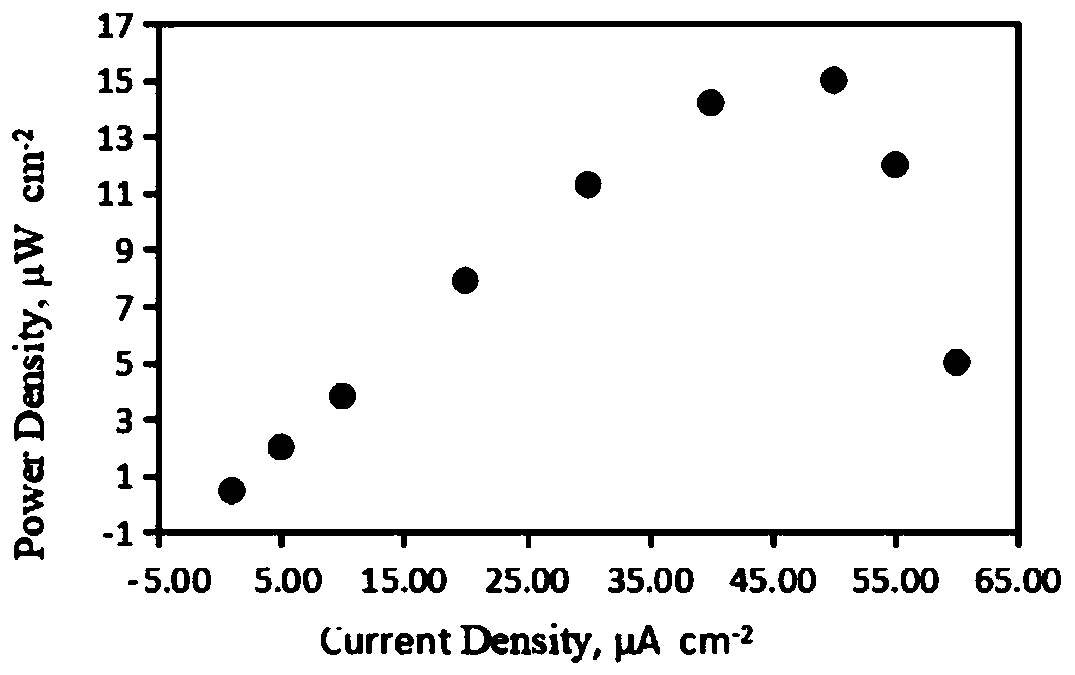

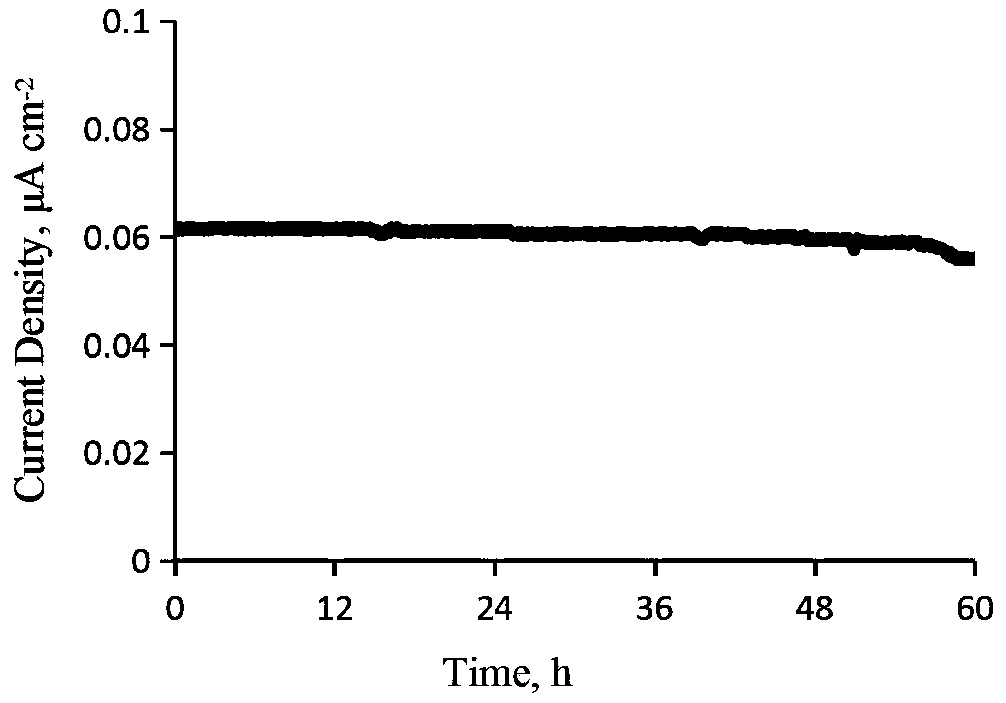

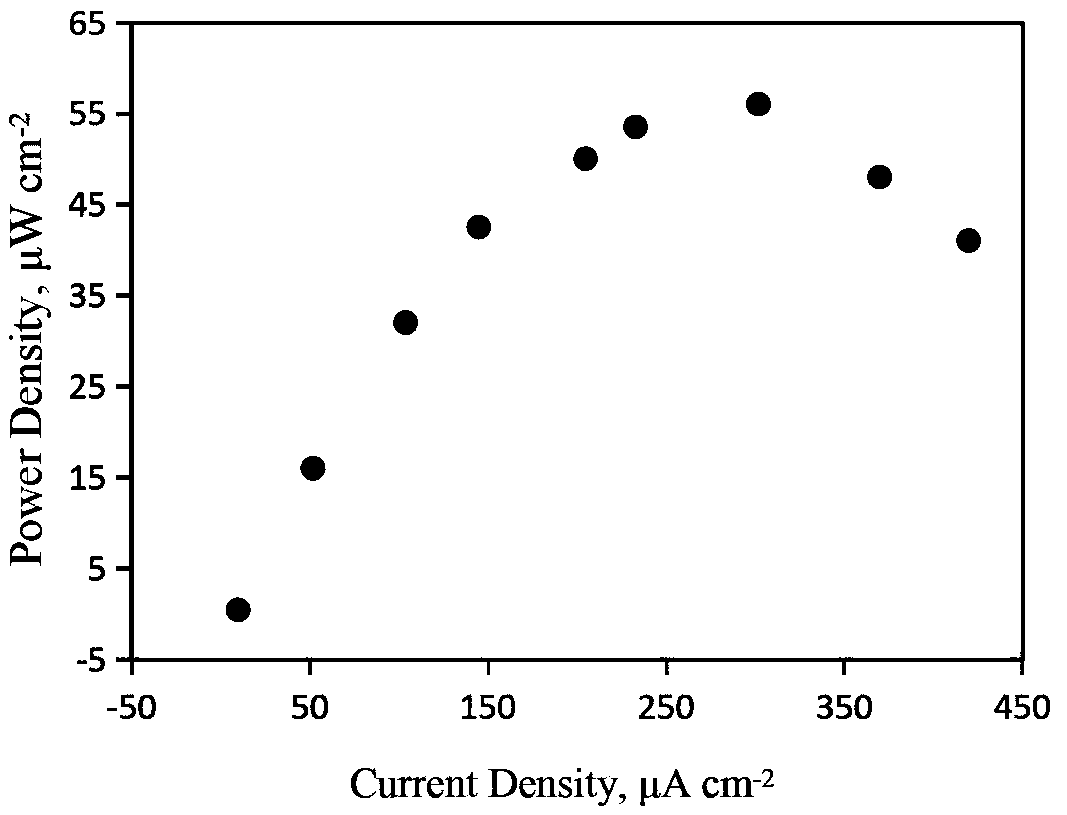

Image

Examples

Embodiment 1

[0026] This example illustrates the preparation method of the bioengineered Escherichia coli of the present invention.

[0027] Extract and amplify the trehalose hydrolase TreA gene from the genome of Escherichia coli str.K-12 substr.MG1655, carry out Nde I and XhoI double digestion of the TreA gene and the vector pet22b(+), and then carry out the digestion fragment The gel was recovered, T4 DNA ligase 16 NA was ligated overnight, and the recombinant plasmid pET22b(+)-TreA was obtained, and the plasmid was transformed into E.coli BL21 competent cells. A single colony was screened out on an ampicillin plate, and colony PCR and subsequent verification were performed. The successfully constructed engineered bacteria are preserved by glycerol cryopreservation, which is the bioengineered Escherichia coli.

Embodiment 2

[0029] This embodiment illustrates the whole cell permeabilization treatment method of bioengineered Escherichia coli of the present invention.

[0030] (1) Get the bacterial classification that embodiment 1 preserves, bacterial classification is inoculated in the LB liquid culture medium that adds ampicillin by volume ratio 1.5%, adds IPTG when measuring OD 600 is 0.6-0.8, keeps the IPTG final concentration of 0.5-1.5mmol / L, induce enzyme production for 7–9h, culture condition is 37°C, 200rpm, obtain fermentation broth; centrifuge to obtain wet bacteria, centrifuge condition is 4°C, 6000rpm, centrifugation time is 10min;

[0031] The formula of LB liquid medium with ampicillin is: peptone 10g / L, yeast powder 5g / L, sodium chloride 10g / L, ampicillin antibiotic 0.1g / L.

[0032] (2) Add glycolipid, lipopeptide or fatty acid biosurfactant solution of 0.1-0.4g / L equal volume to the fermentation broth in step (1) to the wet thalline obtained in step (1), and 20-25°C, react at 100-2...

Embodiment 3

[0035] This example illustrates the preparation method of the enzyme cathode and enzyme anode in the biofuel cell of the present invention.

[0036] Cut two pieces of carbon felt into a geometric area of 8cm 2 rectangle. The carbon felt was ultrasonically cleaned with acetone, ethanol and ultrapure water for 10 min and dried to remove grease, dust or other debris on the surface.

[0037]Soak one of the carbon felts in the bioengineering Escherichia coli fermentation liquid obtained in Example 2 and let it stand at 35-40°C for 2-16 hours, take it out, rinse it with ultrapure water, dry it naturally, and set it aside;

[0038] Soak the cleaned anode carbon felt in engineering Escherichia coli fermentation broth and let it stand at 35-40°C for 2-16 hours, take it out and rinse it with ultra-pure water, and then put in an ultra-pure aqueous solution of 5-25g / L glucose oxidase Stand still at 35-40°C for 16 hours, take it out, wash it with ultrapure water, and store it at 4°C to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com