Composite-type nano attapulgite ceramsite ozone catalyst and preparation method and application thereof

A nano-attapulgite and attapulgite technology, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve low current efficiency, poor wastewater applicability, Problems such as poor catalytic activity, to achieve the effect of increasing reaction speed, efficient treatment, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of composite nano-attapulgite ozone catalyst, comprising the following steps:

[0030] The first step, grinding and forming: select 50g of attapulgite ceramsite with a Mohs strength of 2.5 and a specific gravity of 2.20 as the raw material of attapulgite ceramsite; for auxiliary materials, kaolin is selected as aggregate additive, fly ash is selected as pore-forming agent, and binder Sodium silicate is selected, and the mass dosage ratio is attapulgite: kaolin: fly ash: sodium silicate = 10: 1.2: 0.5: 0.6; the active catalytic component A is a mixture of iron nitrate and iron nitrate nanoparticles, and the mass input The ratio is ferric nitrate: ferric nitrate nanoparticles: attapulgite = 0.02:1.2:100; mix the above materials and grind them into powder; add 12.5mL deionized water according to the dosage of 25mL / 100g, mix evenly into a slurry The mixture is made into spherical particles with a particle diameter of 4mm;

[0031] The second step, dryi...

Embodiment 2

[0050] A preparation method of composite nano-attapulgite ozone catalyst, comprising the following steps:

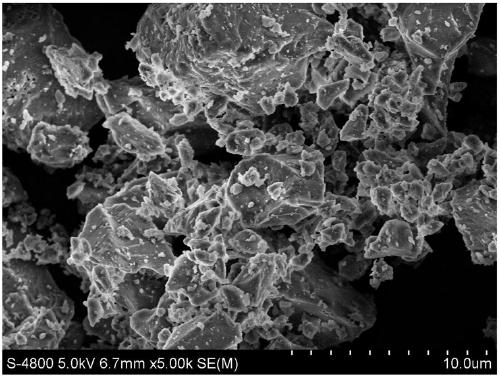

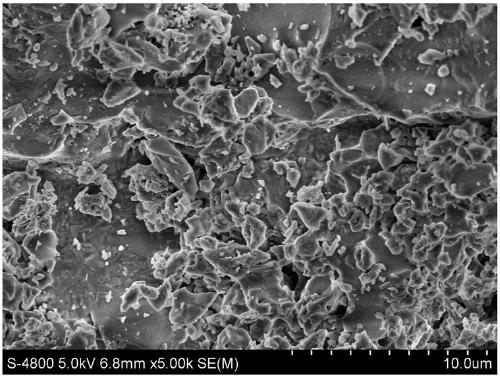

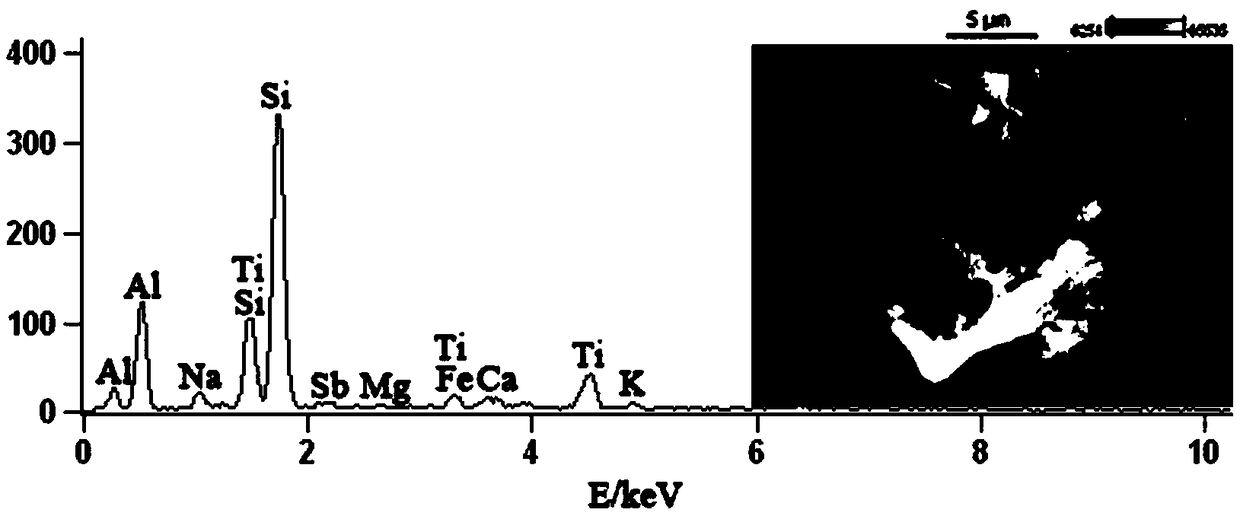

[0051]The first step, grinding and forming: select 60g of attapulgite ceramsite with a Mohs strength of 2.7 and a specific gravity of 2.25 as the attapulgite ceramsite raw material; for auxiliary materials, montmorillonite is selected as the aggregate additive, sodium bicarbonate is selected as the pore-forming agent, and viscose The binder is sodium cellulose, and the mass dosage ratio is attapulgite: montmorillonite: sodium bicarbonate: sodium cellulose = 10: 1.0: 1.0: 2.0; the active catalytic component A is titanium tetrachloride and tetrachloride The mixture of titanium nanoparticles, the mass dosage ratio is titanium tetrachloride: titanium tetrachloride nanoparticles: attapulgite = 0.05:1.5:100; the above materials are mixed and ground to powder; the dosage is 25mL / 100g Add 15.0mL deionized water, mix evenly to form a slurry mixture, and then make spherical partic...

Embodiment 3

[0058] A preparation method of composite nano-attapulgite ozone catalyst, comprising the following steps:

[0059] The first step, grinding and forming: select attapulgite ceramsite 40g with a Mohs strength of 3.0 and a specific gravity of 2.20 as the raw material of attapulgite ceramsite; for auxiliary materials, choose illite as the aggregate additive, and ammonium carbonate as the pore-forming agent. Calcium phosphate is selected as the agent, and the mass dosage ratio is attapulgite: illite: ammonium carbonate: calcium phosphate=10:1.2:0.8:1.0; the active catalytic component A is a mixture of nickel nitrate and nickel nitrate nanoparticles, and the mass input The addition ratio is nickel nitrate: nickel nitrate nanoparticles: attapulgite = 0.5:2.0:100; mix the above materials and grind them into powder; add 8.0mL deionized water according to the dosage of 20mL / 100g, and mix evenly to form a slurry The mixture is made into spherical particles with a particle size of 3.5mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com