Black glass fiber reinforced PBT (Polybutylece Terephthalate) composite material capable of performing laser welding and preparation method of composite material

A laser welding and composite material technology, applied in the field of modified polymer materials, can solve the problems of inability to reach the interface of welding materials, difficult to be welded together, etc., and achieve easy large-scale industrial production, excellent mechanical properties, and operability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

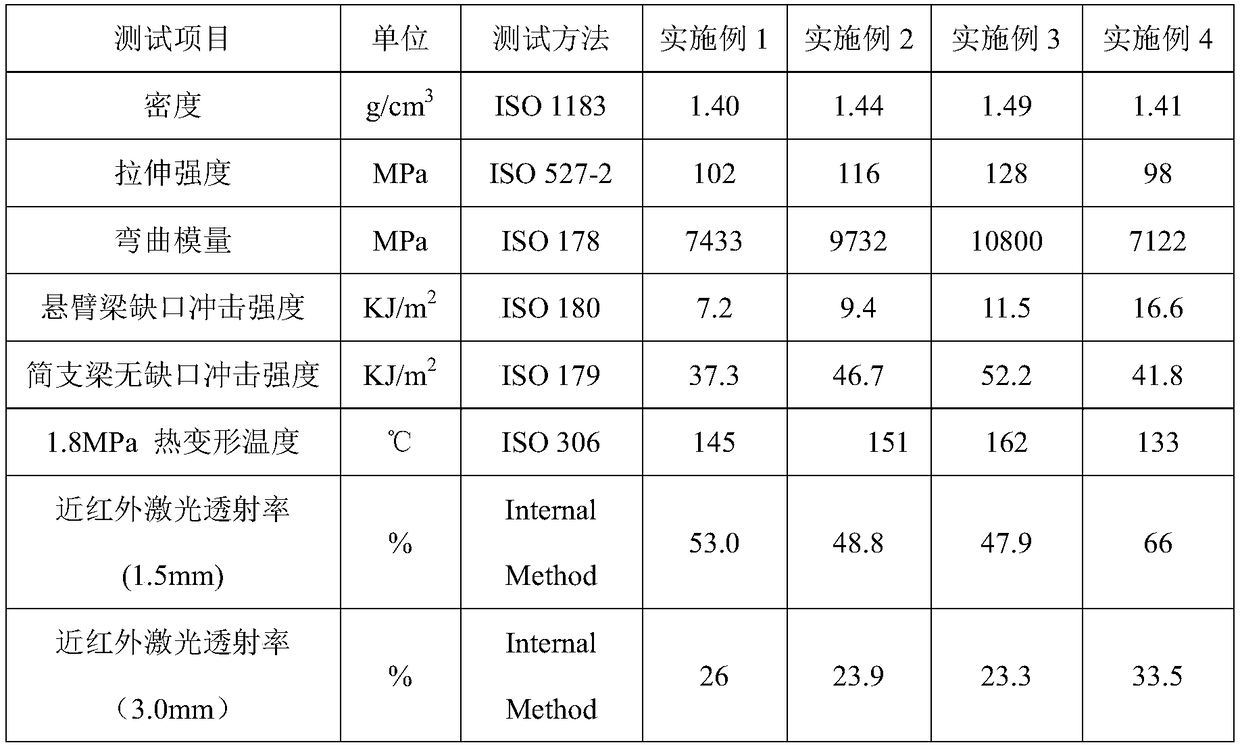

Embodiment 1

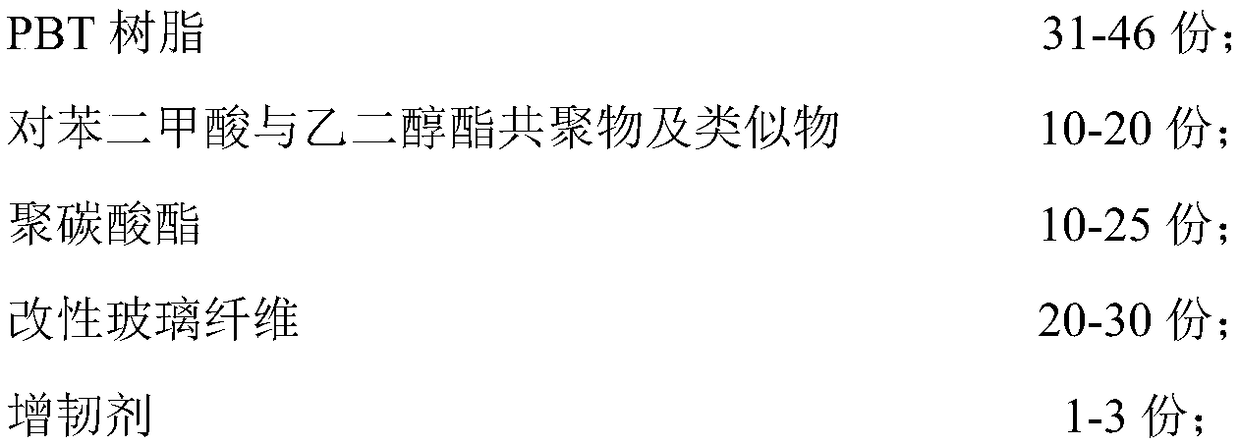

[0027] (1) 31 parts of PBT resin, 20 parts of PET resin, 25 parts of PC resin, 3 parts of ethylene-methyl acrylate copolymer, 1 part of styrene-acrylonitrile-glycidyl methacrylate copolymer, 0.2 parts of polyethylene wax 0.6 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 0.2 parts of phosphorous acid, and 0.1 parts of black powder were added to a high-speed mixer and mixed for 2 minutes to obtain a premixed Material; Wherein, the content of glycidyl methacrylate comonomer in styrene-acrylonitrile-glycidyl methacrylate copolymer is 1wt%, and the mass ratio of each component of black powder is the red dyestuff of perionones : the green dye of ultramarine blue: the blue dye of ultramarine blue: anthraquinone=1:0.85:1.35:0.95;

[0028] (2) Add the premix into the twin-screw extruder through the main feeding hopper, and add 20 parts of alkali-free E-grade chopped glass fiber with a diameter of 9 μm infiltrated by epoxy silane coupling agent at the side feed ...

Embodiment 2

[0030] (1) 41 parts of PBT resin, 15 parts of PET resin, 15 parts of PC resin, 1 part of ethylene-butyl acrylate copolymer, 1 part of ethylene-glycidyl methacrylate copolymer, styrene-acrylonitrile-methyl 2 parts of glycidyl acrylate copolymer, 0.2 parts of pentaerythritol stearate, 0.2 parts of stearic acid, 0.3 parts of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate 1 part, 0.1 part of tris(2,4-di-tert-butylphenyl) phosphite, 0.1 part of sodium pyrophosphate, and 1 part of black powder were added to a high-speed mixer and mixed for 1 min to obtain a premix; among them, styrene-acrylonitrile -The content of glycidyl methacrylate comonomer in the glycidyl methacrylate copolymer is 3wt%, and the mass ratio of each component of the black powder is red dyestuff of perionones: ultramarine green dyes: ultramarines The blue dye: anthraquinones = 1:0.8:1:0.9;

[0031] (2) Add the premixed material into the twin-screw extruder through the main feeding hopper, and add 25...

Embodiment 3

[0033] (1) 46 parts of PBT resin, 10 parts of PET resin, 10 parts of PC resin, 1 part of ethylene-methyl acrylate-glycidyl methacrylate copolymer, styrene-acrylonitrile-glycidyl methacrylate copolymer 3 parts, 0.4 parts of acidified polyethylene wax, 0.2 parts of polyethylene wax, 0.2 parts of tris(2,4-di-tert-butylphenyl) phosphite, 0.03 parts of sodium dihydrogen phosphate, bisphenol A bis-diphenyl phosphoric acid Add 0.02 parts of ester and 1.5 parts of black powder into a high-speed mixer and mix for 2 minutes to obtain a premix; wherein, the content of glycidyl methacrylate comonomer in styrene-acrylonitrile-glycidyl methacrylate copolymer is 5wt %, the mass ratio of each component of the black powder is the red dye of perionones: the green dye of ultramarine blue: the blue dye of ultramarine blue: anthraquinone=1:0.8:1.35:0.95;

[0034] (2) Add the premixed material into the twin-screw extruder through the main feeding hopper, and add 30 parts of alkali-free E-grade chop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com