Preparation method of titanium boride ceramic powder based on ferrosilicon-titanium alloy

A technology of titanium silicon ferrosilicon alloy and ceramic powder, which is applied in the field of preparation of titanium boride ceramic powder, which can solve the problems of high impurity content in the product powder that is difficult to remove, production efficiency and cost unfavorable for industrialization, and difficulty in controlling the size of ceramic powder. , to achieve the effects of narrow particle size distribution, widening the source of raw materials, and improving kinetic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the titanium ferrosilicon alloy is as follows: the titanium-containing blast furnace slag is cold or hot titanium-containing blast furnace slag produced by blast furnace smelting with vanadium-titanium magnetite as the main raw material; 2 The content is 12-30wt%.

[0027] The particle size of the titanium-silicon-iron alloy is ≤0.088mm.

[0028] The titanium-containing blast furnace slag is cold or hot titanium-containing blast furnace slag produced by blast furnace smelting with vanadium-titanium magnetite as the main raw material; 2 The content is 12-30wt%.

[0029] SiO in the sodium silicate 2 with Na 2 The molar ratio of O is ≤1.

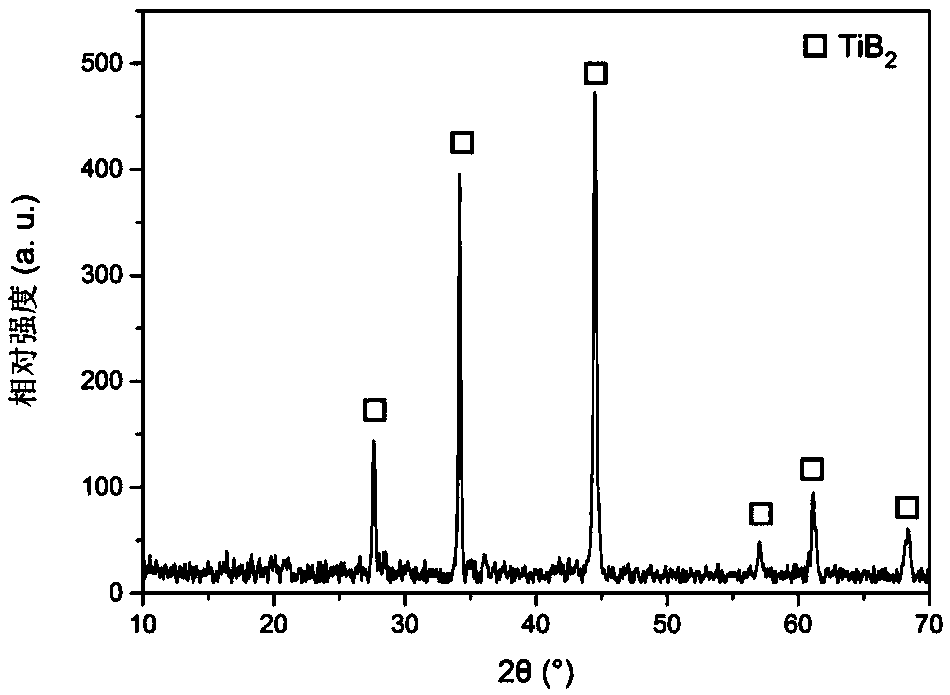

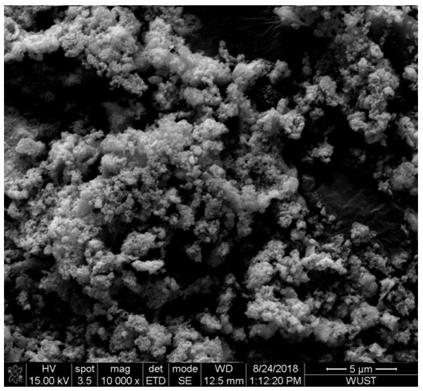

Embodiment 1

[0031] A method for preparing titanium boride ceramic powder based on titanium silicon ferroalloy. The preparation method described in this embodiment is:

[0032] According to the mass ratio of titano-silicon alloy: boron source: the molten salt of alkali metal compound is 1.0: (0.5~1.0): (0.2~5.0), the described titano-silicon alloy, the boron source and the alkali metal compound The molten salt is mixed evenly, heat treated in a protective atmosphere at 1000-1300°C for 6-8 hours, then dissolved in water at 95-200°C, washed, sorted, and dried to prepare titanium boride ceramics based on titanium-silicon-iron alloy Powder.

[0033] The boron source is one of boron gangue, boric acid, sodium tetraborate, potassium tetraborate and lithium tetraborate.

[0034] The molten salt containing alkali metal compound is one of lithium chloride, sodium chloride, potassium chloride, lithium fluoride, sodium fluoride, potassium fluoride, sodium hydroxide, sodium silicate and sodium carbo...

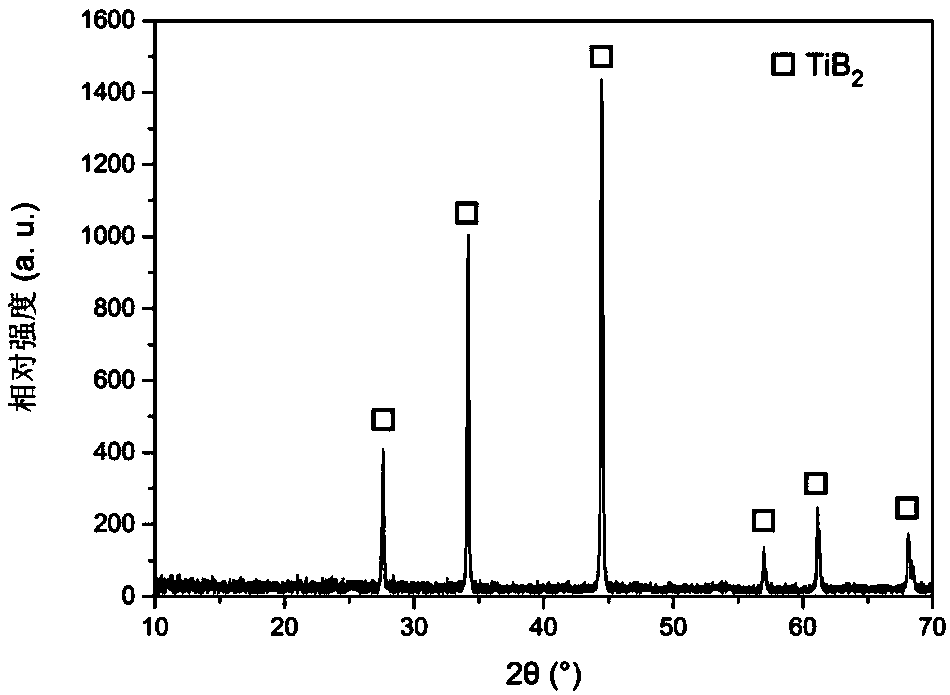

Embodiment 2

[0036] A method for preparing titanium boride ceramic powder based on titanium silicon ferroalloy. The preparation method described in this embodiment is:

[0037] According to the mass ratio of titano-silicon alloy: boron source: the molten salt of alkali metal compound is 1.0: (0.5~1.0): (0.2~5.0), the described titano-silicon alloy, the boron source and the alkali metal compound The molten salt is mixed evenly, heat-treated in a protective atmosphere at 1000-1300°C for 6-8 hours, then dissolved with an alkali solution at 95-200°C, washed, sorted, and dried to obtain boride based on titanium-silicon-iron alloy Titanium ceramic powder.

[0038] The boron source is a mixture of boron gangue, boric acid, sodium tetraborate, potassium tetraborate and lithium tetraborate.

[0039] The molten salt containing alkali metal compound is a mixture of two substances in lithium chloride, sodium chloride, potassium chloride, lithium fluoride, sodium fluoride, potassium fluoride, sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com