Method for activating carbon fiber by colloid copper and preparing chemical plating copper-nickel duplex metal layer by one-step

A double-metal layer and electroless copper plating technology, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problem that it is difficult to form a continuous and uniform metal coating, it is difficult to form a continuous and uniform, and the amount of chemical plating raw materials Many problems, to achieve the effect of reducing and harm to the human body, good coverage, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

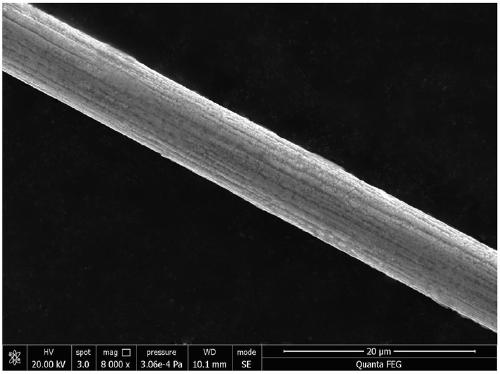

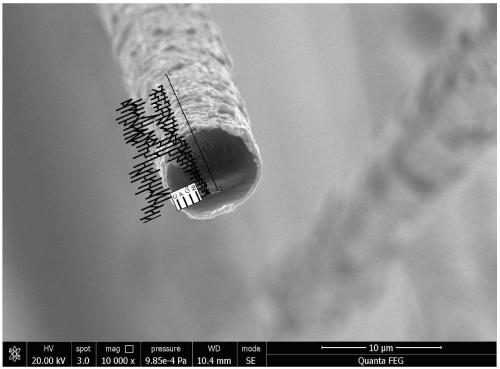

[0055] This embodiment is a method for activating carbon fiber with colloidal copper and preparing an electroless copper-nickel bimetallic layer in one step.

[0056] The specific implementation steps of this embodiment are:

[0057] Step 1. Carbon fiber surface pretreatment

[0058] 1. Degumming: Put the carbon fiber in the argon protective atmosphere of the tube furnace at 400°C for 30 minutes at high temperature for degumming treatment;

[0059] 2. Dispersion: Submerge the degummed carbon fiber into the polyethylene glycol dispersant, and ultrasonically treat it at room temperature for 10 minutes;

[0060] 3. Degreasing: Prepare an aqueous solution containing 50g / L sodium hydroxide, 15g / L sodium carbonate, and 30g / L sodium phosphate as a degreasing agent, immerse the dispersed carbon fibers in the degreasing agent, and Soak at 50°C for 35 minutes;

[0061] 4. Coarsening: prepare 200g / L ammonium sulfate and 100mL / L sulfuric acid solution as the roughening solution, and im...

Embodiment 2

[0079] This embodiment is a method for activating carbon fiber with colloidal copper and preparing an electroless copper-nickel bimetallic layer in one step.

[0080] The specific implementation steps of this embodiment are:

[0081] The steps are the same as the carbon fiber surface pretreatment process in Example 1, including degumming, dispersing, degreasing, roughening, neutralizing, activating, and degumming.

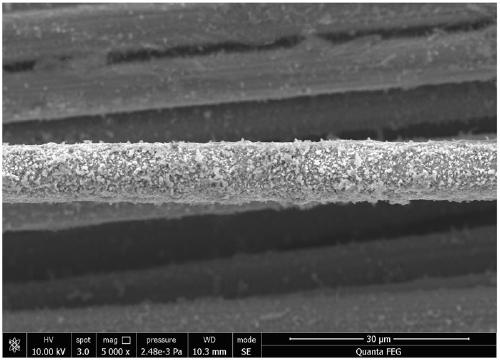

[0082] Step 2, one-step chemical plating of copper-nickel bimetallic layer on carbon fiber surface

[0083] (1) Weigh 10 g of copper sulfate pentahydrate and dissolve it in 900 mL of deionized water, and stir it electromagnetically for 5 min;

[0084] (2) Weigh 1g of nickel sulfate, 25g of sodium citrate, 30g of boric acid, 10mg of 2.2'-bipyridine, 50mg of sodium benzenesulfinate, and 6.5mg of methyl orange into the above solution, and stir it electromagnetically 10min;

[0085] (3) Weigh 30 g of sodium hypophosphite and dissolve it in 100 mL of deionized water,...

Embodiment 3

[0090] This embodiment is a method for activating carbon fiber with colloidal copper and preparing an electroless copper-nickel bimetallic layer in one step.

[0091] The specific implementation steps of this embodiment are:

[0092] The steps are the same as the carbon fiber surface pretreatment process in Example 1, including degumming, dispersing, degreasing, roughening, neutralizing, activating, and degumming.

[0093] Step 2, one-step chemical plating of copper-nickel bimetallic layer on carbon fiber surface

[0094] (1) Weigh 10 g of copper sulfate pentahydrate and dissolve it in 900 mL of deionized water, and stir it electromagnetically for 5 min;

[0095] (2) Weigh 4g of nickel sulfate, 25g of sodium citrate, 30g of boric acid, 10mg of 2.2'-bipyridyl, 50mg of sodium benzenesulfinate, and 6.5mg of methyl orange into the above solution, and stir it electromagnetically 10min;

[0096] (3) Weigh 30 g of sodium hypophosphite and dissolve it in 100 mL of deionized water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com