One-component solvent-free polyurethane adhesive for photovoltaic module back panel compounding and preparation method of polyurethane adhesive

A solvent-free polyurethane and polyurethane adhesive technology, applied in polyurea/polyurethane adhesives, adhesive additives, polymer adhesive additives, etc., can solve safety and health hazards, fire and explosion hazards, large equipment investment, etc. problem, achieve high initial bonding strength, excellent hydrolysis resistance, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

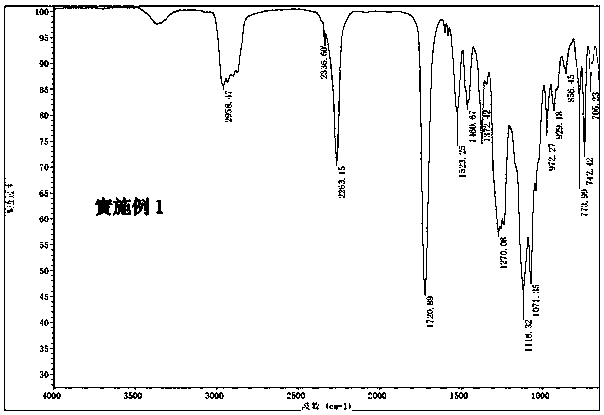

[0091] like figure 1 As shown, the present invention prepares a kind of method for the one-component solvent-free polyurethane adhesive of photovoltaic module backboard compound and comprises the following steps:

[0092] Use two kinds of polyol esters: polyneopentyl glycol phthalate (molecular weight is 1000), polyoxypropylene diol molecular weight is (molecular weight is 1000), in stirring reactor, drop into above-mentioned two kinds of raw materials, in addition, again An antioxidant is added, and the amount of the antioxidant added is 0.15-0.5% of the total weight of the raw materials.

[0093] Heat and melt the raw materials in the stirring polymerization reactor, stir and mix evenly, heat slowly so that the temperature of the material reaches 110-120°C, vacuumize the reactor to reduce the vacuum degree in the reactor to below 50torr, and then start dehydration, and continue the negative pressure state 1- After 3 hours, fill with nitrogen and return to normal pressure to...

Embodiment 2

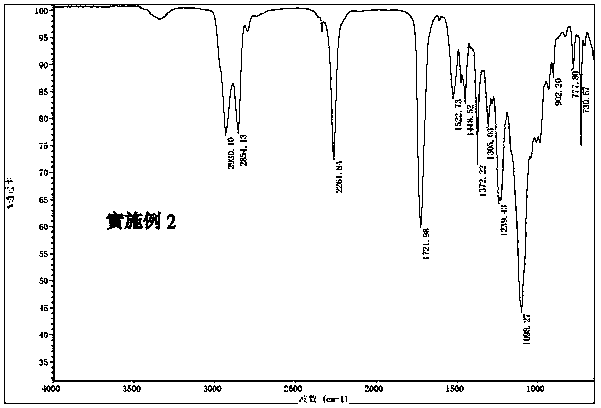

[0102] The process of this embodiment is the same as that of Example 1, the difference is: polyneopentyl adipate isophthalate (molecular weight is 2200), polytetramethylene ether glycol (molecular weight is 1000), polyoxyethylene Propylene glycol (molecular weight is 400), the weight ratio is set to 400:400:200. In the formula, the equivalent ratio of isocyanate group to hydroxyl group is 1.7:1, the diisocyanate is hydrogenated phenylmethane diisocyanate (H12MDI), which improves the initial bonding performance of the adhesive, the antioxidant is hindered phenolic antioxidant CHINOX 1010, and the catalyst is Dibutyltin dilaurate and increase the addition amount to improve the curing speed after processing and compounding. The leveling agent is acrylate copolymer polymer MODAFLOW Resin, and the light stabilizer is 2-(2'-hydroxy-5'methyl)-benzene Triazole (CHISORB P).

[0103] The basic formula of the present embodiment product is as follows (weight ratio):

[0104] Table 3 Examp...

Embodiment 3

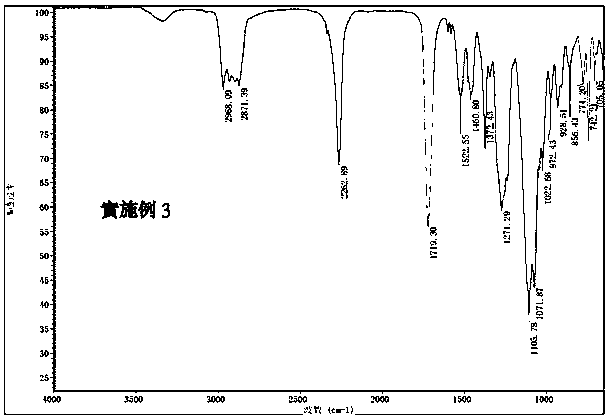

[0110] The present embodiment polyol ester uses polyneopentyl glycol phthalate (molecular weight is 1000), polyethylene adipate (molecular weight is 1000), polyoxypropylene glycol (molecular weight is 400) , the weight ratio is set to 400:300:200. The equivalent ratio of isocyanate group to hydroxyl group in the formula is 1.65:1, the isocyanate is isophorone diisocyanate (IPDI), the antioxidant is hindered phenolic antioxidant CHINOX 1010, the catalyst is dibutyltin dilaurate, and the leveling agent is The agent is acrylate copolymer polymer MODAFLOW Resin, and the light stabilizer is 2-(2'-hydroxy-5'methyl)-benzotriazole (CHISORB P).

[0111] The basic formula of the present embodiment product is as follows (weight ratio):

[0112] Table 4 Example 3 product basic formula

[0113]

[0114]

[0115] Finally, perform a performance test, such as Figure 4 The infrared spectrogram analysis shown, followed by aging performance is shown in Table 5.

[0116] performance an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com