Negative electrode of secondary battery and preparation method thereof, and secondary battery

A secondary battery and negative electrode technology, applied in the direction of electrode manufacturing, battery electrodes, electrode carriers/collectors, etc., can solve problems such as complex process routes, achieve simple process routes, facilitate large-scale production and application, and realize light and thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

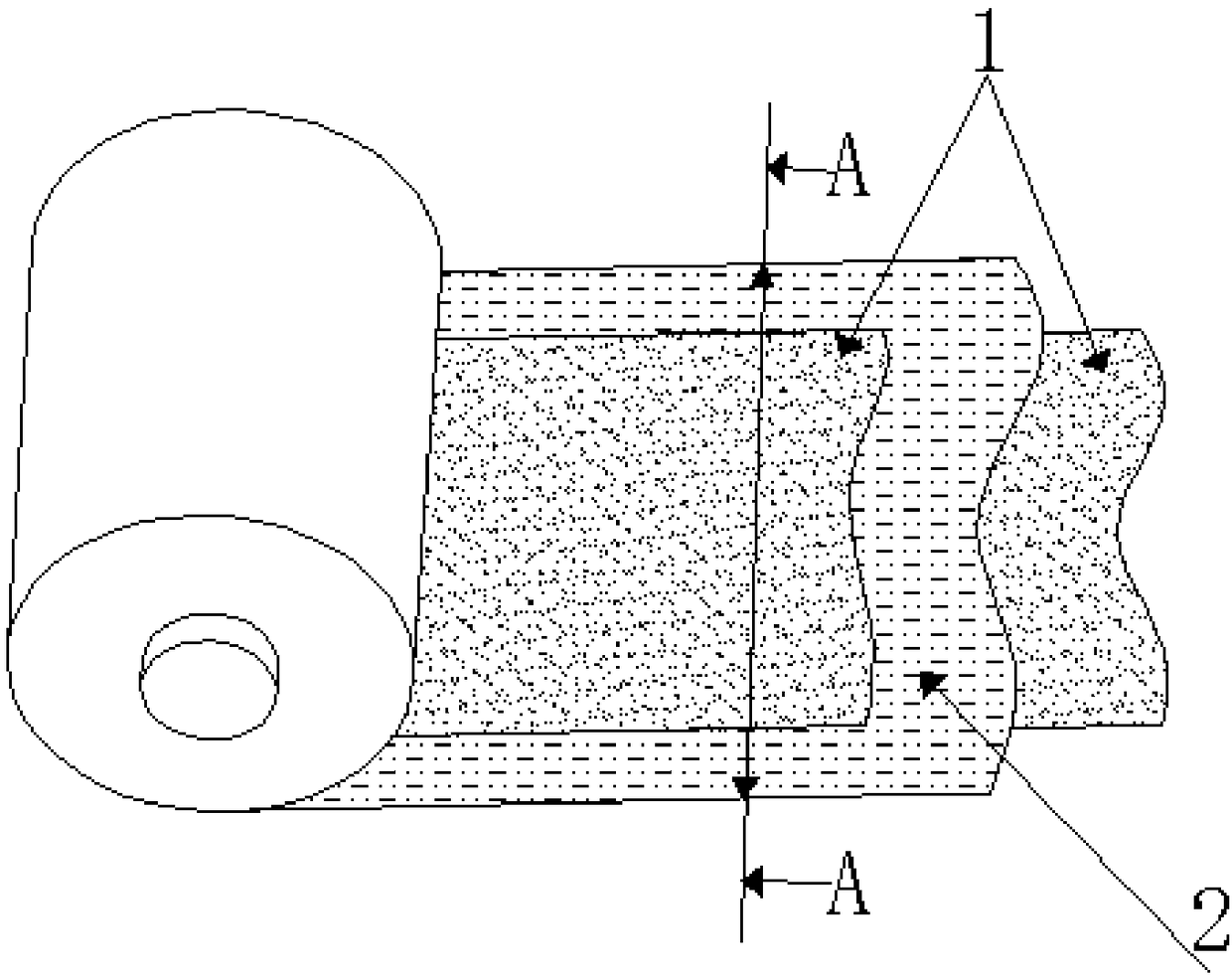

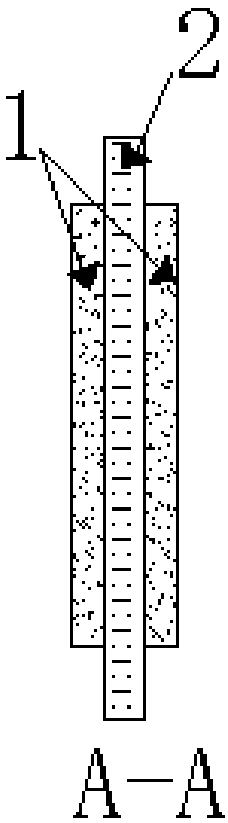

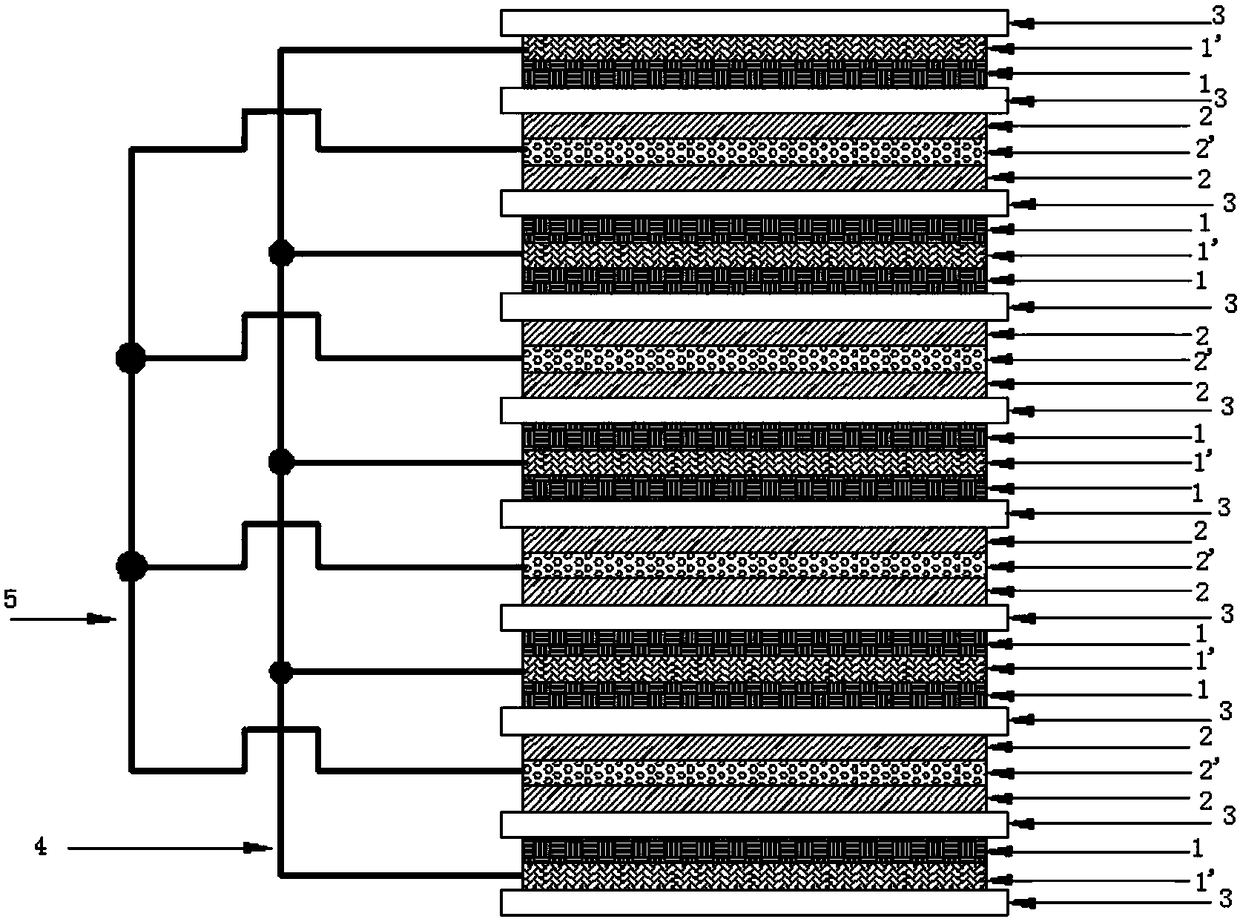

[0043] The current collector copper foil (Lingbao Huaxin Copper Foil Co., Ltd., thickness 10 microns, the same below) is coated with 30 microns thick lithium on both sides as the negative electrode; the positive electrode active material uses elemental sublimed sulfur (Nanjing reagent) and graphene ( Chinese Academy of Sciences Chengdu Organic Chemistry Co., Ltd., a mixture of purity greater than 97wt%, diameter less than 6um (graphene doping is 5%), conductive agent activated carbon (Shenzhen Kejing Zhida Technology Co., Ltd., the same below), bonding PVDF (polyvinylidene fluoride, Zhejiang Funuolin New Chemical Material Co., Ltd., the same below), positive electrode active material: activated carbon: binder in a mass ratio of 8:1:1, add solvent NMP (Shanghai Aladdin Biochemical Technology Co., Ltd., the same below), mixed into a slurry, coated on a current collector aluminum foil (Gongyi Tianlong Aluminum Co., Ltd., thickness 10 microns, the same below) to prepare a positive e...

Embodiment 2

[0045] Take 20 micron lithium plated on both sides of the current collector copper foil as the negative electrode; weigh 20 mg of activated carbon and 15 mg of PTFE in an agate mortar, then add 1.5 ml of N-methylpyrrolidone as a solvent, and grind for 30 minutes . The uniformly mixed sample was scraped on a glass plate by scraping, with a scraper thickness of 200 microns, and dried in natural air for 5 hours, and then dried in a vacuum drying oven at 80°C for 12 hours to prepare a positive electrode active material film, and then use 20MPa The positive electrode active material film is compounded on the current collector foam nickel (thickness: 0.25mm, Jiangsu Geye New Material Technology Co., Ltd.) to obtain the lithium oxygen battery positive electrode. Electrolyte uses 1M LiPF 6 EC / DMC / EMC (vol 1 / 1 / 1, EC: ethylene carbonate, DMC: dimethyl carbonate, EMC: ethyl methyl carbonate, Dongguan Shanshan Battery Material Co., Ltd., the same below), the separator is glass fiber Membr...

Embodiment 3

[0047] Solid electrolyte preparation: press 75Li 2 S (Bai Lingwei Technology): 25P 2 S 5 (Nanjing Reagent) The stoichiometric ratio is placed in a ball milling tank and mixed uniformly, and high-energy ball milling is performed at 500 rpm for 15 hours to obtain the LPOS amorphous precursor. Then the precursor is placed in a muffle furnace at 250 ℃ for heat treatment for 6 hours to obtain Li 3 PS 4 Glass ceramic electrolyte.

[0048] According to the positive electrode active material NCA (Nickel Cobalt Aluminum Ternary Material, Shenzhen Beiterui New Energy Material Co., Ltd.): activated carbon: PVDF = 8:1:1 ratio (mass ratio), solvent NMP, stir evenly, and paste The material is coated on a 10-micron aluminum foil and dried in a vacuum drying oven at 60°C for 24 hours for use; the negative electrode is a product with 35 micron thick lithium plated on both sides of the current collector; the positive electrode, solid electrolyte, and negative electrode are assembled into a battery f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com