A stabilization coating technique for enteric feed biological vitamins

A vitamin and enteric-soluble technology, which is applied in the field of stable coating technology of enteric-coated biological vitamins for feed, can solve the problems of death, long-term stability without liquid package stabilization technology, etc., and achieve the effect of long storage time and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

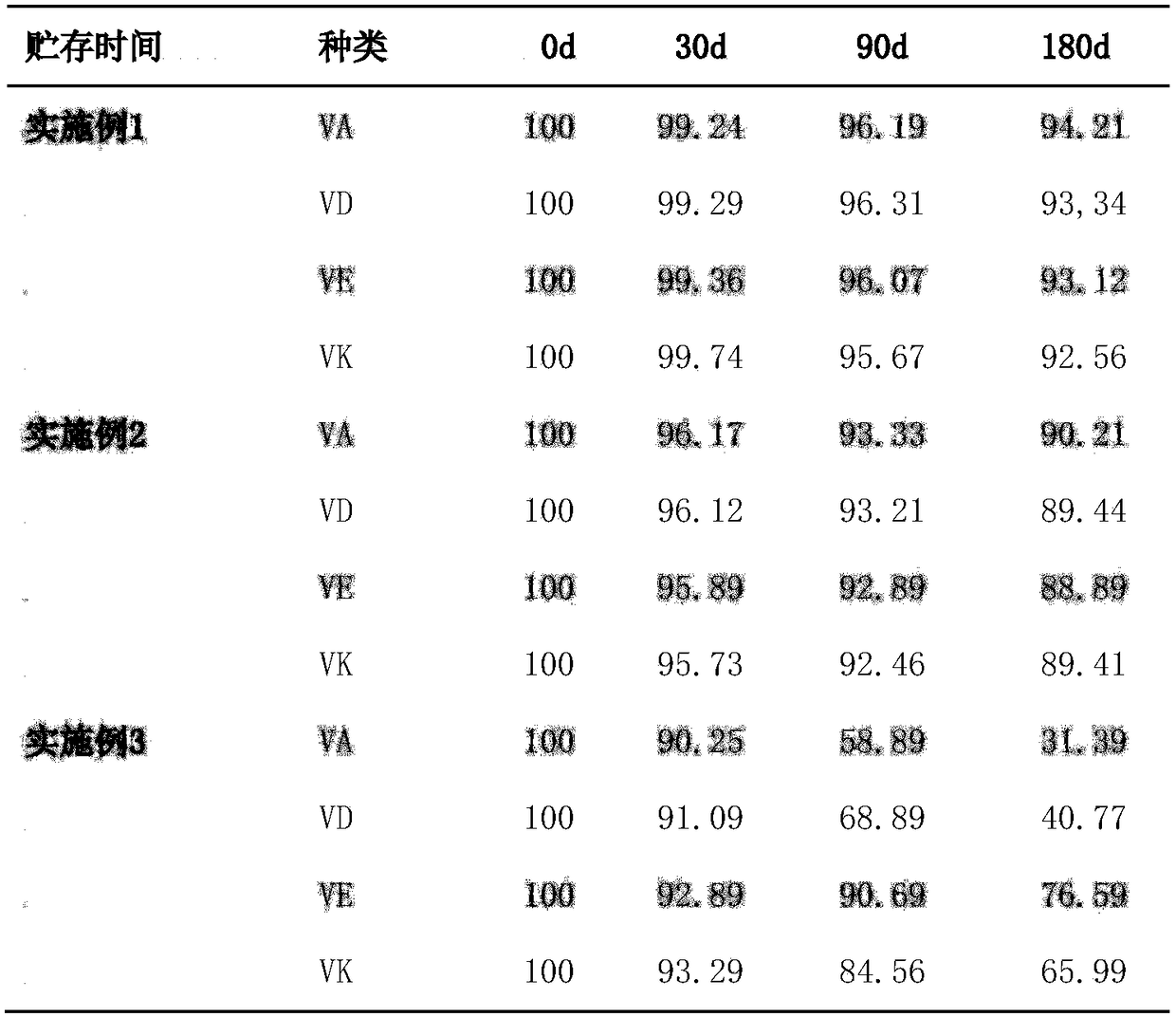

Embodiment 1

[0033] Screening of lactic acid bacteria culture medium. Including components A, B, C and D, wherein the component A is a mixture of one or more of glucose, sucrose, corn starch, and soybean meal; the component B is peptone, yeast extract, yeast extract One or more mixtures in powder, beef extract, malt extract, described component C is, ferric sulfate, calcium carbonate, ferric chloride, potassium dihydrogen phosphate, dipotassium hydrogen phosphate, magnesium sulfate, sodium chloride One or more mixtures; the components are one or more mixtures of biotin, vitamin B2, vitamin A, vitamin C, and the culture medium of the above-mentioned A, B, C, D combination is at 115 ℃ Sterilize for 50 min and cool to room temperature.

[0034] The lactic acid bacteria (eg, Enterococcus faecalis) screened from animal intestines or feces are inserted into the above-mentioned medium for 18-25 hours at 36°C, and the lactic acid bacteria liquid is centrifuged at 10,000 r / min to obtain a viable b...

Embodiment 2

[0040] The yeast (such as Saccharomyces cerevisiae) preserved in the laboratory was inserted into the medium in Example 1 and cultivated at 30-40°C for 18-25 hours, and the yeast fermentation broth was centrifuged at 10,000 r / min to obtain viable bacteria. Concentration of 10 11 -10 12 Lactic acid fermented concentrated milk.

[0041] Biological multi-dimensional granulation

[0042] In the fermented milk of 10 parts by weight, add fermented milk, the glycerol of glycerol weight ratio 10:1 successively and stir, then add the gelatin solution of 8% (W / V) pH4.0-4.5 (solid content and lactic acid fermented milk) The weight ratio is (6:3), the emulsification is uniform, and the protective agent solution with a mass fraction of 10% (the solid content of the solution is mixed according to the mass ratio of fermented milk: skimmed milk powder: sodium glutamate: lactose 60:36:1:6) Evenly) emulsification 30min, obtain the emulsion of fermented milk.In above-mentioned emulsion, add t...

Embodiment 3

[0046] The lactic acid bacteria (such as Lactobacillus johnsonii) screened from animal intestines or feces are inserted into the medium in Example 1 and cultured at 30-40°C for 18-25 hours. Under the condition of / min, the concentration of viable bacteria obtained by centrifugation was 10 11 -10 12 Lactic acid fermented concentrated milk.

[0047] Biological multi-dimensional granulation

[0048] 10 parts by weight of fermented milk were successively added with fermented milk and glycerol in a weight ratio of 10:1 and stirred evenly,

[0049] Then add 8% (W / V) gelatin solution of pH 4.0-4.5 (solid content and lactic acid fermented milk weight ratio is (6:3) to emulsify evenly, mass fraction 10% protective agent solution (solid content of solution) Content, according to fermented milk: skimmed milk powder: sodium glutamate: lactose mass ratio 60:36:1:6 mix and stir) emulsification 30min, obtain the emulsion of fermented milk.In above-mentioned emulsion, add the adjuvant of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com