Filling material for bone defect repairing and preparation method

A technology for filling materials and bone defects, applied in pharmaceutical formulations, pharmaceutical science, capsule delivery, etc., can solve the problems of poor treatment effect and high price, and achieve the effect of reducing treatment time and pain, low price and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of Rabbit Demineralized Bone Matrix

[0038] Add 30 mL / g of rabbit bone to a chloroform / methanol (1:1) solution to degrease for 8 hours, pour off the organic solvent, and rinse with double distilled water for 3 times. Dehydrate with ethanol 5 times the volume of the bone block for 2 h. Put the bone into a deep-low temperature refrigerator to freeze for 4 hours, take it out and grind it in a grinder with liquid nitrogen at low temperature, and use a sample sieve to sieve bone particles of 200-800 μm in size. Put bone particles into 0.6M hydrochloric acid solution for decalcification according to the ratio of dilute hydrochloric acid to bone weight of 20:1, stir every half hour, and replace with new decalcification solution every 8 hours, and decalcification is completed in about 24 hours. Rinse with double distilled water until the pH is around 7.0. Degrease again with chloroform / methanol (1:1) for 4 hours, wash with double distilled water 3 time...

Embodiment 2

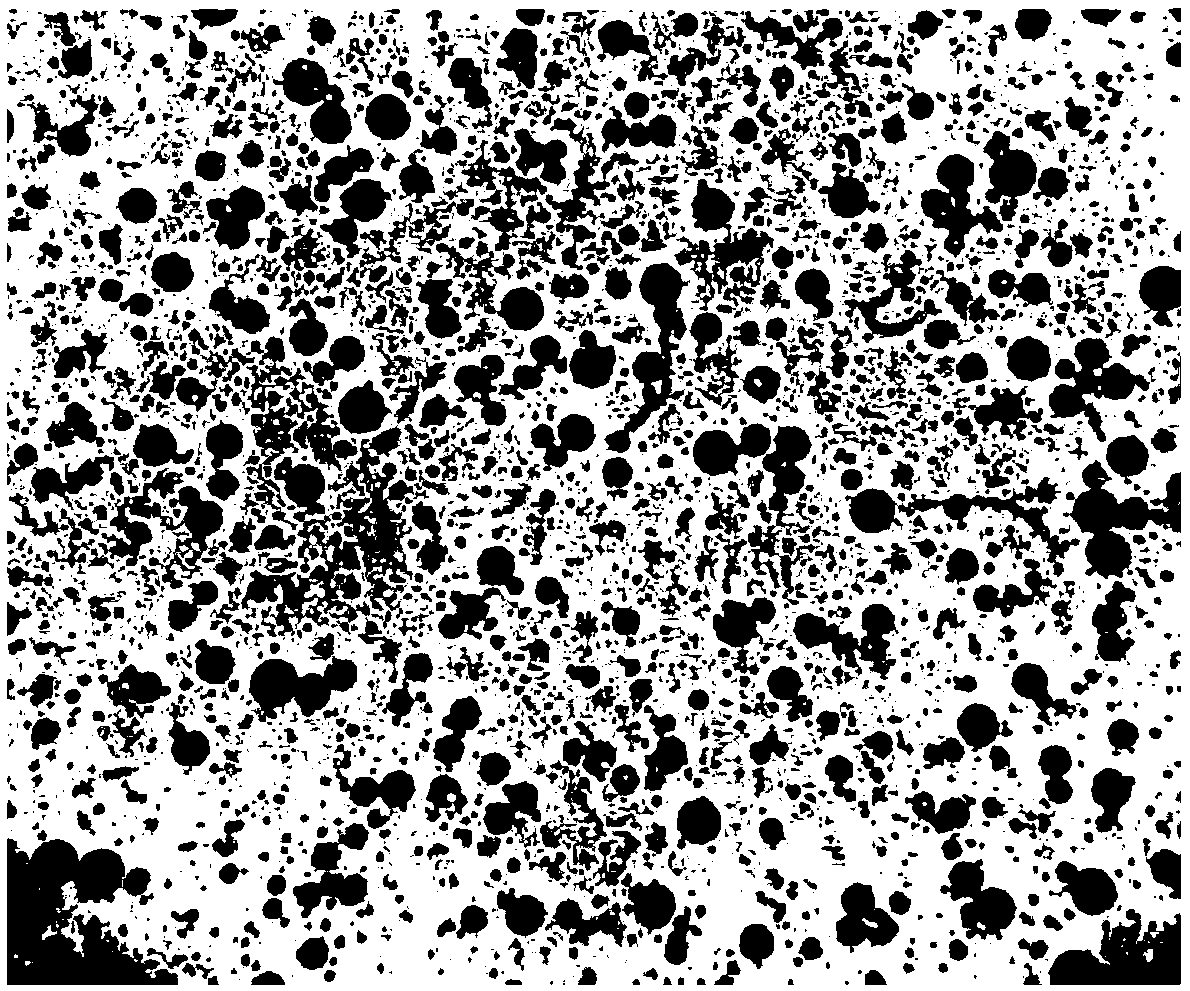

[0039] Embodiment 2: flavone sustained-release microcapsules

[0040] Use a pipette to accurately draw 0.4 mL of flavone solution as the inner aqueous phase. Under vortex stirring, the flavonoid solution was rapidly added dropwise to a 140 mg / mL PLGA solution in 4 mL of dichloromethane, and quickly transferred to a homogenizer at a speed of 1500 rpm, stirred and emulsified for 5 min to form colostrum. Then add the colostrum into 10mL of 1% polyvinyl alcohol solution, stir and emulsify at high speed in a vortex for several minutes to form double emulsion. Move it to 20mL of 1% polyvinyl alcohol solution in a fume hood and magnetically stir for 4h to remove methylene chloride, centrifuge at 5000rpm in a high-speed centrifuge for 10min, collect the supernatant, take the microcapsules at the bottom of the test tube, wash with double distilled water, dry and Freeze-drying yields a light yellow powder.

Embodiment 3

[0041] Example 3: Preparation of Plastic Bone Clay for Grafting

[0042] 1) Under room temperature, in a clean operating table, accurately weigh carboxymethylcellulose (CMC) and demineralized bone matrix (DBM) and mix them evenly, and grind them into powder;

[0043] 2) adding flavonoid slow-release microcapsules to the mixture in step 2) to make a finished package;

[0044] 3) The mixture was sterilized under 25kGy gamma rays and stored at -20°C for future use.

[0045]Accurately weigh and mix according to the ratio of CMC:DBM=130mg:870mg, divide them into 4 groups at random, each group has the same bone cement weight. Add high (2.4mg), medium (1.2mg) and low (0.6mg) doses of flavonoid PLGA microcapsules to three groups, make finished products in a clean bench, and store them at -20°C for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com