Metal monatomic/N co-doped 3D (Three Dimensional) structure nano porous carbon and preparation method thereof

A nanoporous carbon, co-doping technology, applied in nanocarbon, nanotechnology for materials and surface science, nanotechnology, etc., to achieve the effects of high nitrogen content, short reaction time, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

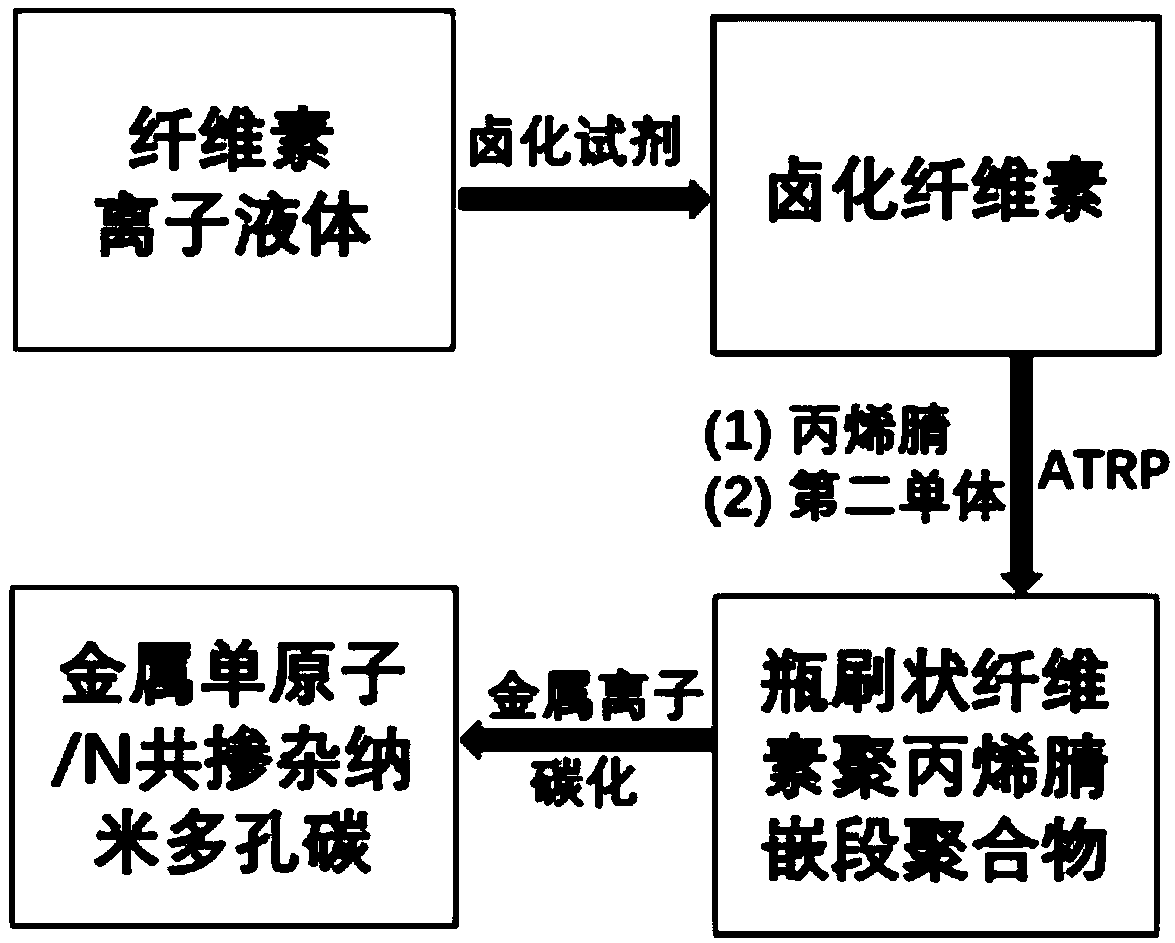

[0048] Example 1: Monoatomic iron / N co-doped 3D structure nanoporous carbon, the schematic diagram of its preparation process is shown in the figure:

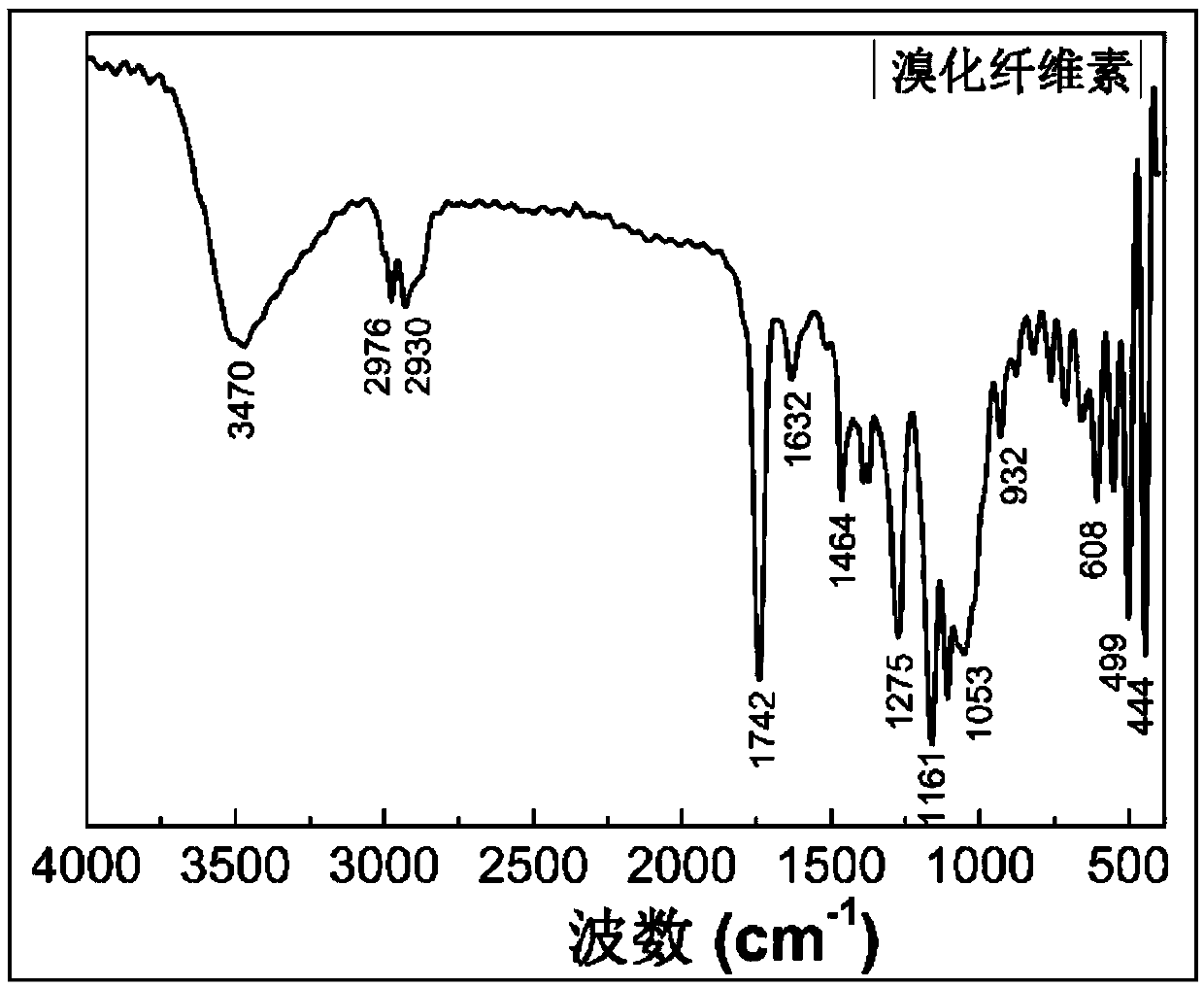

[0049] First, dissolve 0.5 g of cellulose in 10.0 g of 1-allyl-3-methylimidazole to form a uniform solution; then add a certain amount of 2-bromoisobutyryl bromide and then proceed to the heating reaction, wherein the halogenation reagent 2 - The molar ratio of bromoisobutyryl bromide to the hydroxyl group in cellulose is 0.5, and the reaction solution is repeatedly precipitated and purified to obtain brominated cellulose polymer;

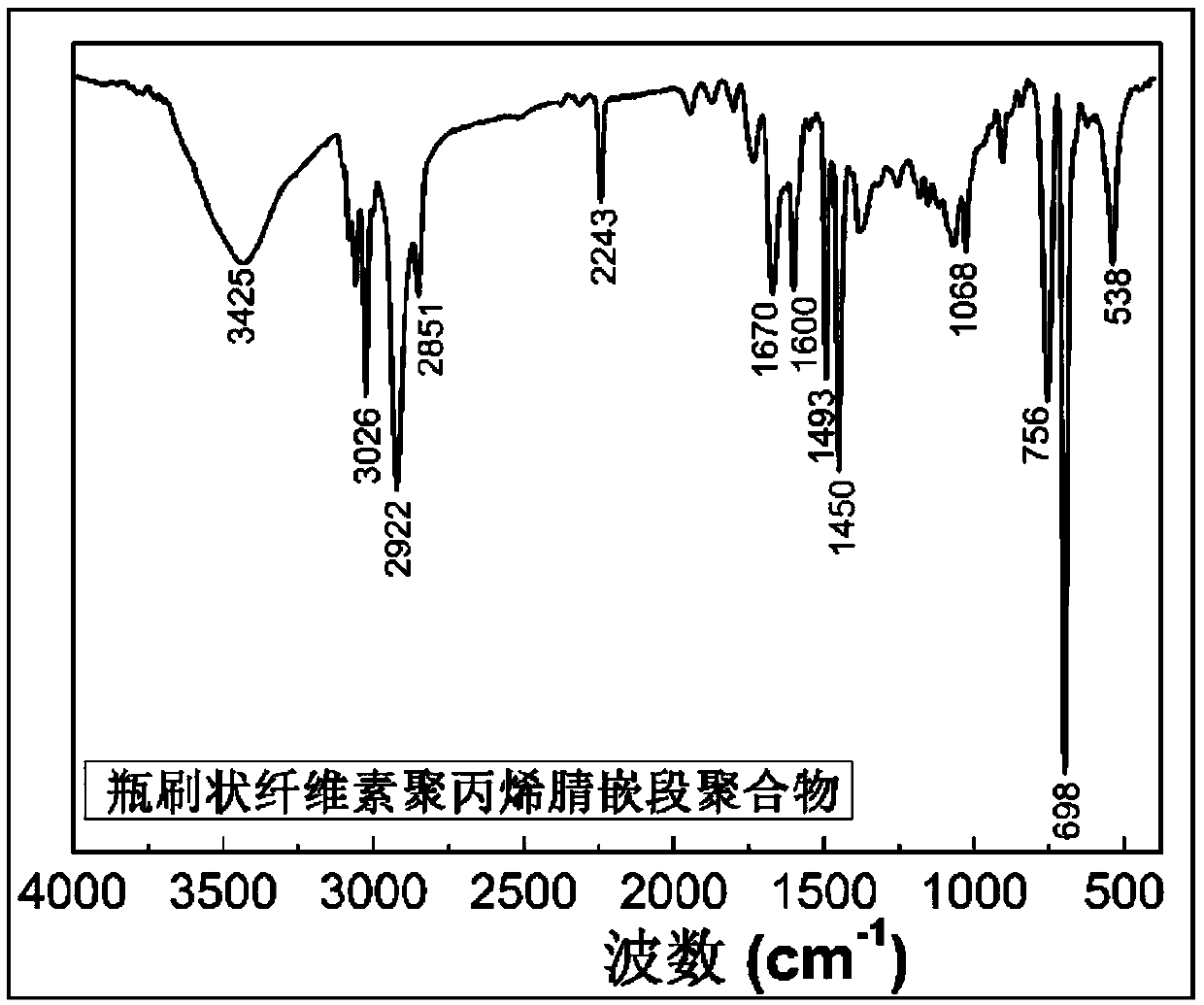

[0050] Dissolve 10mg of brominated cellulose polymer in N,N-dimethylformamide, then add 20ml of acrylonitrile, 10mg of copper bromide and 10mg of 2,2'-bipyridine, deoxygenate with nitrogen, and freeze with liquid nitrogen , add 30 mg of cuprous bromide, heat up to 60°C and polymerize for 5-12 hours, add styrene monomer, continue the polymerization for 8-24 hours, measure the monomer conversion rate ...

Embodiment 2

[0057] Example 2: Monoatomic Fe / N co-doped 3D structured nanoporous carbon

[0058] First dissolve 0.5g of cellulose in 10.0g of 1-ethyl-3-methylimidazolium bromide to form a uniform solution; add a certain amount of 2-bromo-2-methylpropionyl chloride and then carry out the temperature rise reaction, wherein The molar ratio of the halogenation reagent 2-bromo-2-methylpropionyl chloride to the hydroxyl group in the cellulose is 1, and the reaction solution is repeatedly precipitated and purified to obtain a brominated cellulose polymer;

[0059] Dissolve 200 mg of brominated cellulose polymer in dimethyl sulfoxide, then add 20 ml of acrylonitrile, 3 mg of copper chloride and 200 mg of 4,4'-dinonyl-2,2'-bipyridine, and remove the After oxygen and liquid nitrogen freezing, add 30 mg of cuprous chloride, heat up to 60 ℃, polymerize for 5-12 hours, add styrene monomer, continue polymerization for 8-24 hours, and measure the monomer by nuclear magnetic resonance (NMR) After the con...

Embodiment 3

[0063] Example 3: Single atom cobalt / N co-doped 3D structured nanoporous carbon

[0064] First, dissolve 0.5g of cellulose in 10.0g of 1-ethyl-3-methylimidazolium bromide to form a uniform solution; add a certain amount of 4-chlorobutyryl chloride and then proceed to the heating reaction, in which the halogenation reagent 4-chlorobutyryl The molar ratio of butyryl chloride to the hydroxyl group in the cellulose is 2, and the reaction solution is repeatedly precipitated and purified to obtain a chlorinated cellulose polymer;

[0065] Dissolve 200 mg of chlorinated cellulose polymer in dimethyl sulfoxide, then add 20 ml of acrylonitrile, 3 mg of copper chloride and 200 mg of 4,4'-dinonyl-2,2'-bipyridine, and remove the After oxygen and liquid nitrogen freezing, add 27 mg of cuprous chloride, heat up to 60 ℃, polymerize for 5-12 hours, add styrene monomer, continue polymerization for 8-24 hours, and measure the monomer by nuclear magnetic resonance (NMR) After the conversion rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com