Flame-retardant compound, preparation method and application thereof

A technology of compounds and flame retardants, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. cracks and other problems, to achieve the effect of low dielectric loss, excellent dielectric constant, and reduce electron migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The present invention further provides a preparation method of the compound, comprising reacting the phosphorus-containing compound with solid phosgene or phosgene.

[0076] Specifically, the aforementioned manufacturing method is to react the phosphorus-containing compound with solid phosgene or phosgene in a solvent under reflux; the reflux time can be between 1 hour and 10 hours, preferably between 2 hours and 10 hours, For example, between 4 hours and 8 hours; the reaction temperature of heating to reflux is between 50°C and 200°C, preferably between 50°C and 120°C, such as between 70°C and 120°C.

[0077]In a preferred embodiment, the molar ratio of phosphorus-containing compound to solid phosgene or phosgene is between 12:1 and 1:1, preferably between 10:1 and 3:1, for example 10:1 and Between 4:1, 10:1 and 5:1.

[0078] In a preferred embodiment, the solvent is toluene (TL), dimethylacetamide (DMAC), dimethylformamide (DMF), 2-propanol methyl ether (PM), propyle...

preparation example 1

[0153] Preparation Example 1: Preparation of Formula (IV) Compound

[0154] Insert a thermometer and a condenser into a 2000 ml three-necked flask, then add 1000 ml of toluene and 0.9 moles (about 195 grams) of DOPO, heat (about 80°C) and stir to dissolve until clear and transparent. Then the solid phosgene (0.1 mol, 29.8 g) dissolved in toluene is transferred to the constant pressure funnel, slowly dripped into the flask under the protection of nitrogen, and heated to the boiling point of the solvent or to a temperature above the boiling point (for example, 120° C. ) for reflux reaction. After reacting for 6 hours, it was cooled to room temperature, filtered, and vacuum-dried to obtain a white powder with a yield of 92.5%.

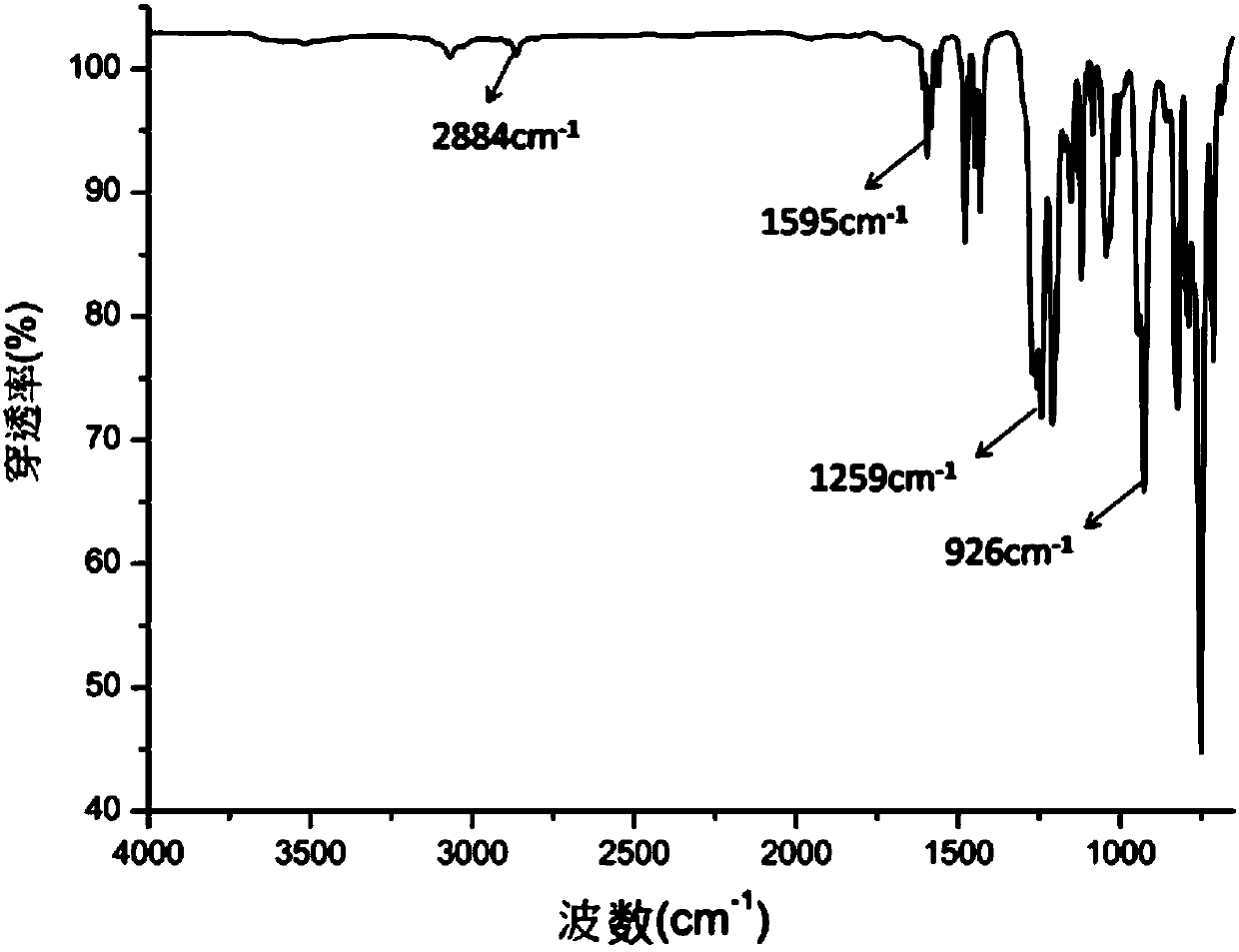

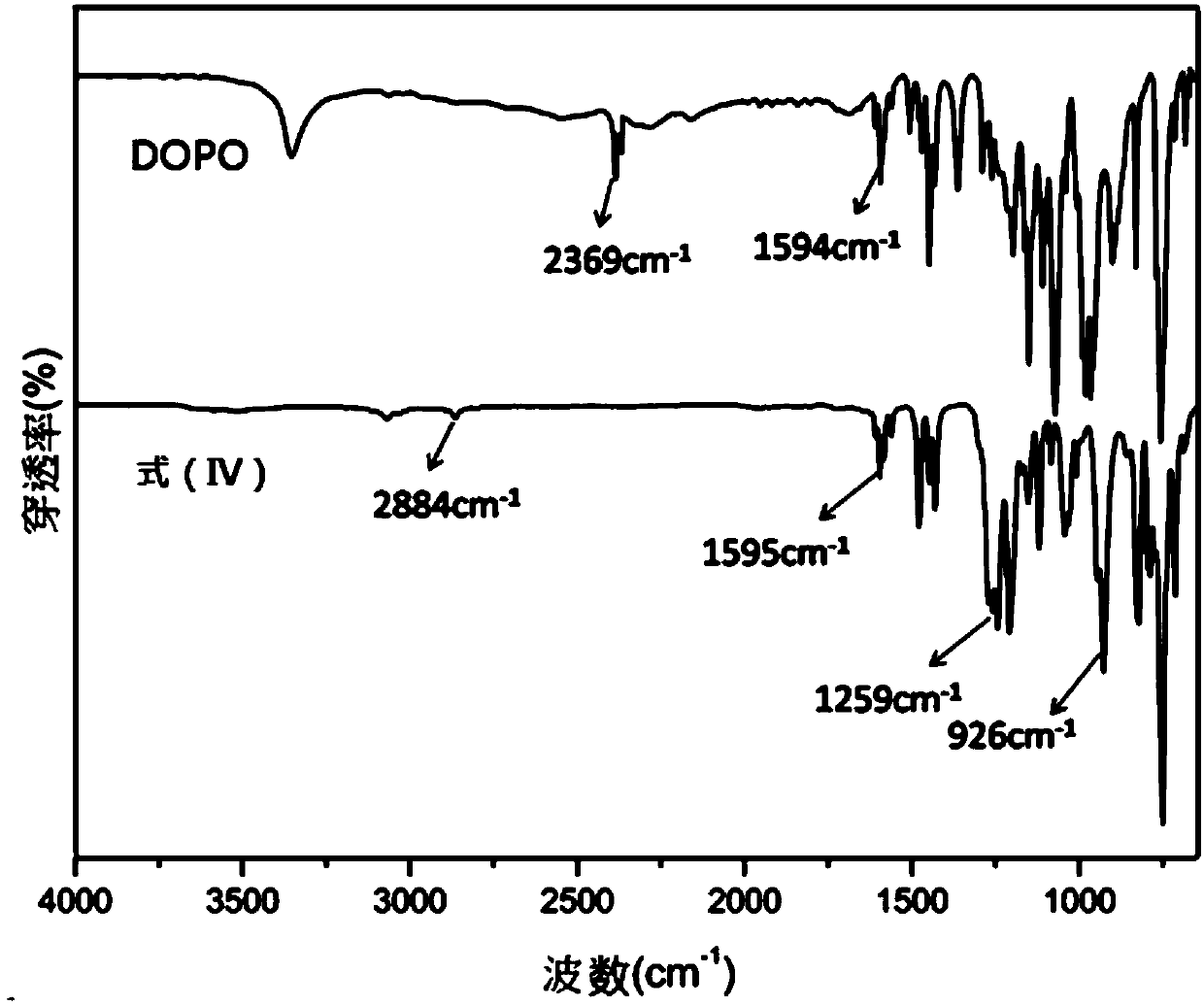

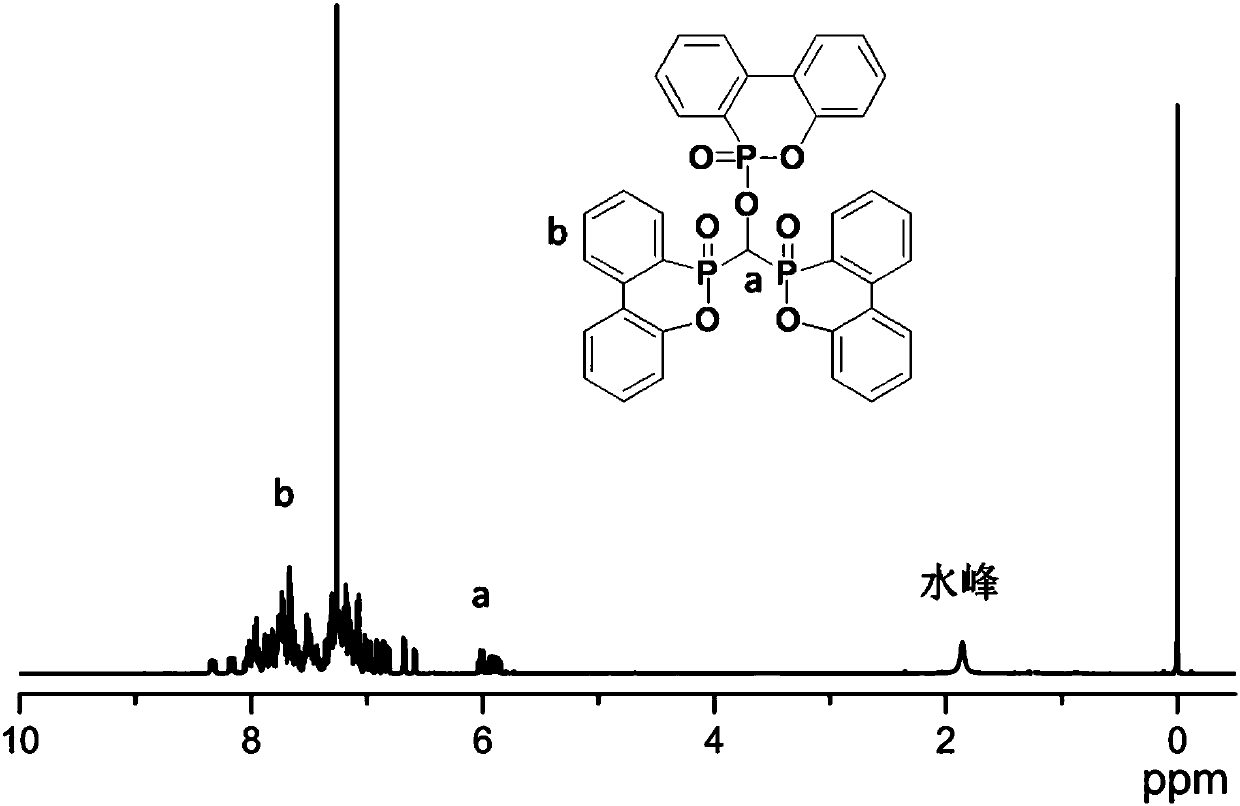

[0155] With reflective Fourier transform infrared spectroscopy (Fourier transform infrared spectroscopy, FTIR) analysis of the resulting white powder, the analysis results are as follows Figure 1A and 1B shown. Among them, by Figure 1A It can be seen...

preparation example 2

[0156] Preparation example 2: preparation of formula (V) compound

[0157] In a 2000 ml three-necked bottle, insert a thermometer and a condenser tube, add 1000 ml of toluene and 1 mole (about 202 g) of DPPO, heat (about 80°C) and stir to dissolve until clear and transparent. Then the solid phosgene (0.1 mol, 29.8 g) dissolved in toluene was transferred to a constant pressure funnel, and slowly dropped into the flask under nitrogen protection for reflux reaction (solvent boiling point or temperature above boiling point, for example 120° C.). After reacting for 6 hours, it was cooled to room temperature, filtered, and vacuum-dried to obtain a white powder with a yield of 91.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com