Granular solid corrosion inhibitor and preparation method thereof

A granular solid and corrosion inhibitor technology, which is applied in the field of metal material anticorrosion, can solve the problems of high investment cost of dosing equipment, inability to prolong the corrosion control cycle, and difficulty in meeting corrosion inhibition requirements, so as to achieve controllable dissolution rate and ensure service life , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

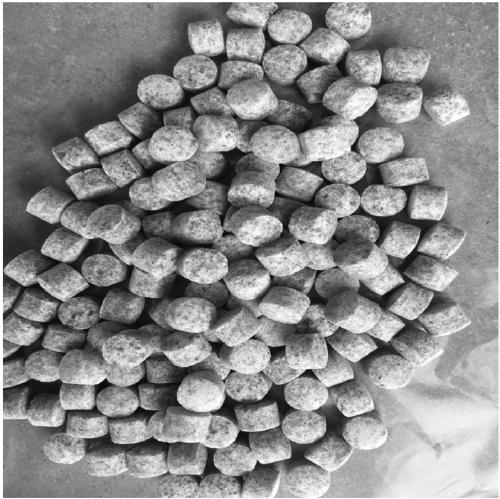

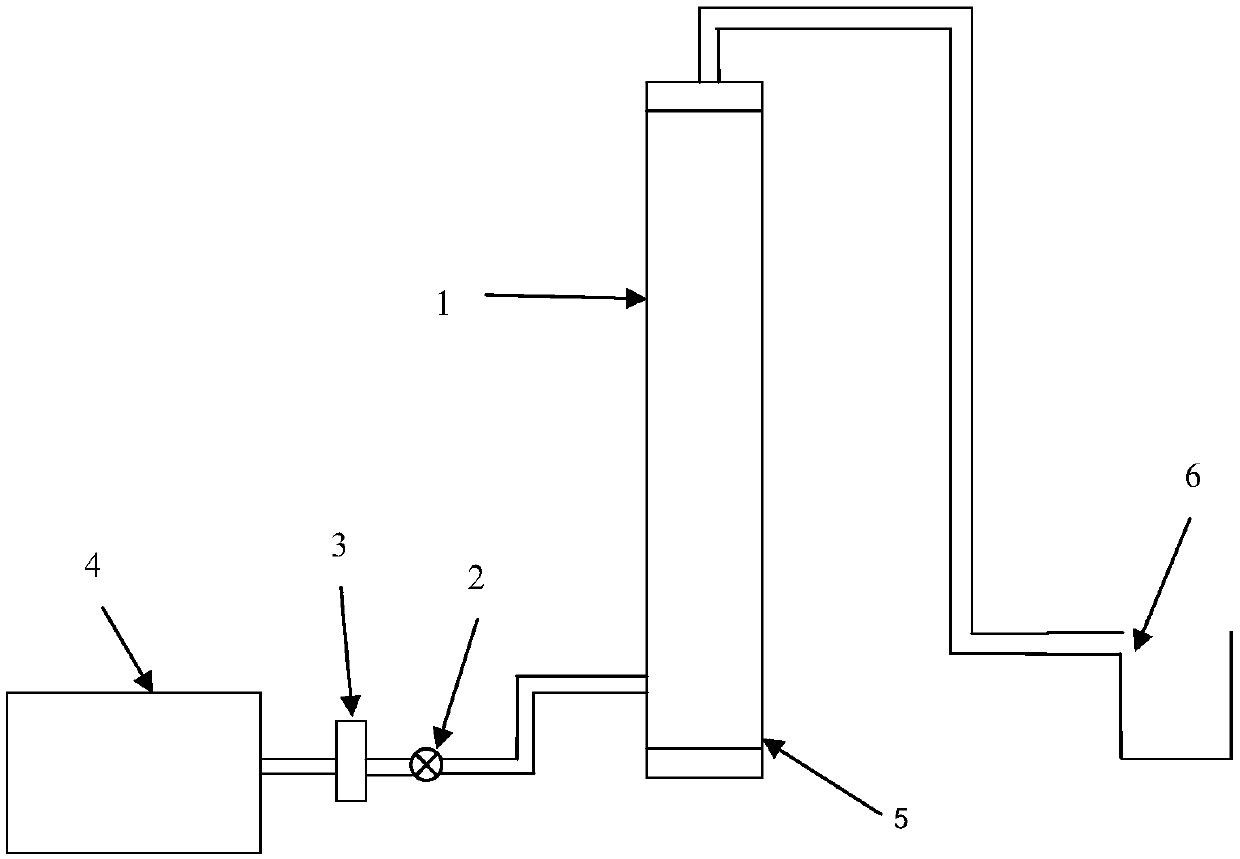

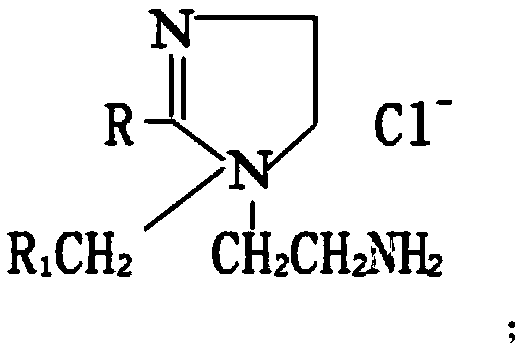

[0069] The granular solid corrosion inhibitor of the present embodiment, see figure 1 , with a particle size of 5-10mm, including corrosion inhibitor particles and coating materials coated on the surface of the corrosion inhibitor particles; the corrosion inhibitor particles are composed of the following components in parts by weight: 50 parts of corrosion inhibitor main agent, synergistic 5 parts of agent, 4 parts of film forming agent, 11 parts of binder, 3 parts of lubricant, 5 parts of nonionic surfactant and 22 parts of weighting agent; the main corrosion inhibitor used is imidazoline quaternary ammonium oleate; The synergist is composed of hexamethylenetetramine and sodium nitrite, and the mass ratio of hexamethylenetetramine and sodium nitrite is 1:1; the film-forming agent is precrossed starch; the adhesive is made of petroleum resin and Composed of polyvinyl alcohol, the mass ratio of petroleum resin and polyvinyl alcohol is 7:4; the lubricant is PEG4000; the nonionic...

Embodiment 2

[0077] The granular solid corrosion inhibitor of this embodiment has a particle size of 5-10 mm, including corrosion inhibitor particles and coating materials coated on the surface of the corrosion inhibitor particles; the corrosion inhibitor particles are composed of the following components in parts by weight: 55 parts of main corrosion inhibitor, 5 parts of synergist, 2.5 parts of film-forming agent, 7.5 parts of binder, 3 parts of lubricant, 7 parts of nonionic surfactant and 20 parts of weighting agent; the main corrosion inhibitor used It is imidazoline quaternary ammonium benzoate; the synergist is composed of hexamethylenetetramine and sodium nitrite, and the mass ratio of hexamethylenetetramine and sodium nitrite is 1:1; the film-forming agent is pregelatinized Starch; adhesive is composed of petroleum resin and polyvinyl alcohol, the mass ratio of petroleum resin and polyvinyl alcohol is 2:1; lubricant is PEG4000; nonionic surfactant is AEO-9; weighting agent is sodiu...

Embodiment 3

[0085] The granular solid corrosion inhibitor of this embodiment has a particle size of 5-10 mm, including corrosion inhibitor particles and coating materials coated on the surface of the corrosion inhibitor particles; the corrosion inhibitor particles are composed of the following components in parts by weight: 50 parts of main corrosion inhibitor, 8 parts of synergist, 21 parts of film-forming agent, 4 parts of adhesive, 4 parts of lubricant, 5 parts of nonionic surfactant and 25 parts of weighting agent; the main corrosion inhibitor used It is imidazoline quaternary ammonium salicylate; the synergist is composed of hexamethylenetetramine and sodium nitrite, and the mass ratio of hexamethylenetetramine and sodium nitrite is 0.5:1; the film-forming agent is composed of carboxymethyl Base starch sodium and precrossed starch, the mass ratio of carboxymethyl starch and precrossed starch is 5:2; the binder is polyvinyl alcohol; the lubricant is talc; the nonionic surfactant is NP-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com