Method for resource utilization of waste lithium ion battery roasting tail gas

A lithium-ion battery, resource-based technology, applied in battery recycling, recycling technology, alkali metal fluoride and other directions, can solve secondary pollution resources, not mentioned activated carbon and alkaline hydroxide or oxide recycling process , waste and other problems, to achieve the effect of low energy consumption, resource utilization, and low reagent cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

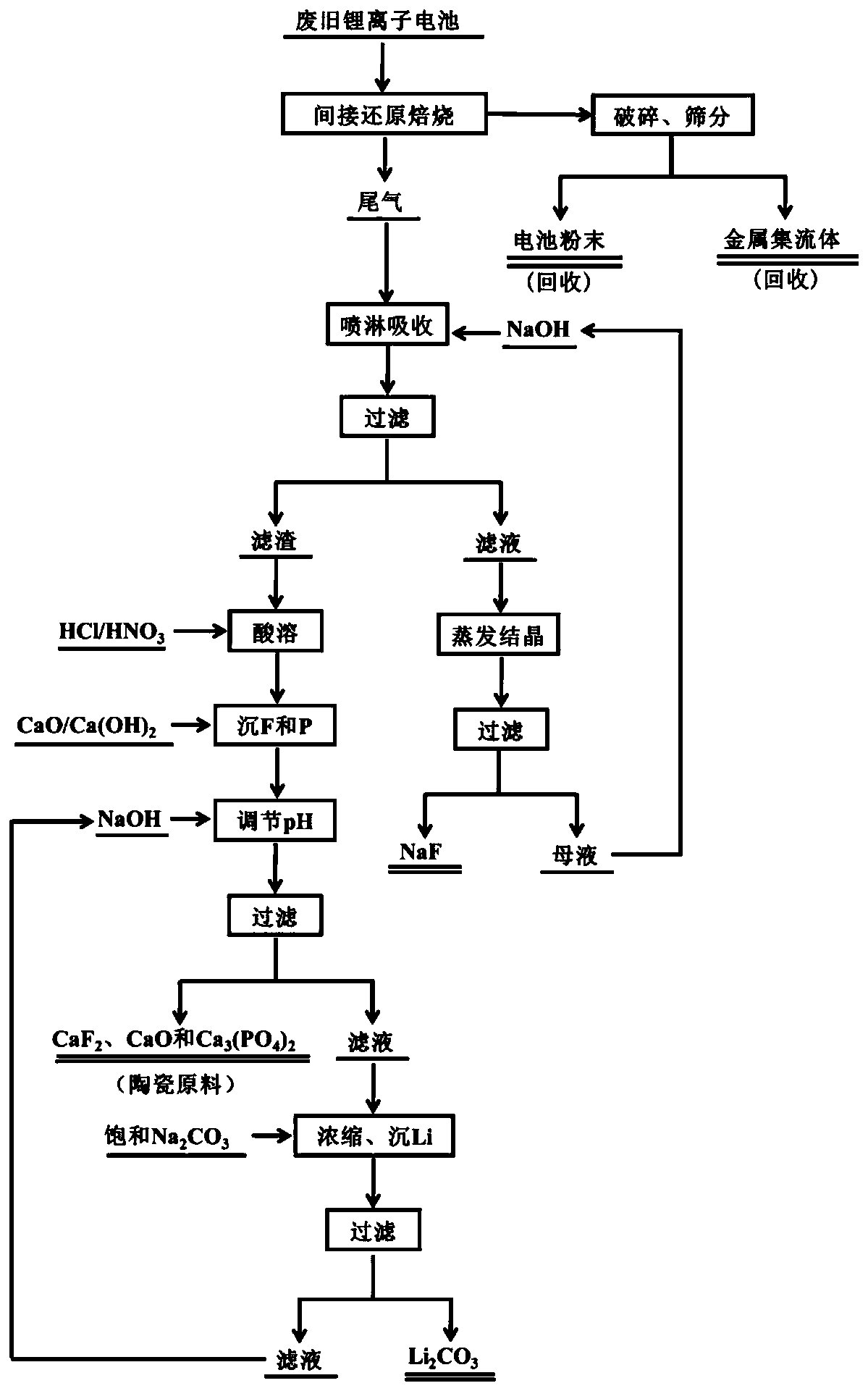

Image

Examples

Embodiment 1

[0021] The waste lithium iron phosphate battery was placed in a rotary kiln for indirect reduction roasting, the roasting temperature was controlled at 500°C, and the roasting time was 2h. Use 1mol / L sodium hydroxide solution to spray and absorb the roasting tail gas to F - The concentration is 8.0g / L, and the filter residue containing lithium phosphate and lithium fluoride and the filtrate containing sodium fluoride are obtained by filtration. The filtrate was evaporated and crystallized at 120°C, and when the volume was evaporated to 31% of the volume of the original filtrate, it was filtered immediately, and the obtained filtrate was a crystal of sodium fluoride. Dissolve the filter residue with 6mol / L hydrochloric acid, add calcium oxide 1.2 times the total molar weight of F and P, and at the same time add 3mol / L sodium hydroxide to adjust the pH to 8.5, and filter to obtain calcium fluoride, calcium oxide and calcium phosphate The mixed filter residue and lithium-contain...

Embodiment 2

[0023] The waste nickel-cobalt-manganese ternary battery was placed in a rotary kiln for indirect reduction roasting, the roasting temperature was controlled at 550°C, and the roasting time was 2h. Use 2mol / L sodium hydroxide solution to spray and absorb the roasting tail gas to F - The concentration is 8.5g / L, and the filter residue containing lithium phosphate and lithium fluoride and the filtrate containing sodium fluoride are obtained by filtration. The filtrate was evaporated and crystallized at 125°C, and when the volume was evaporated to 28% of the volume of the original filtrate, it was filtered immediately, and the filtrate obtained was a crystal of sodium fluoride. Dissolve the filter residue with 5 mol / L hydrochloric acid, add calcium oxide 1.3 times the total molar weight of F and P, and at the same time add 3 mol / L sodium hydroxide to adjust the pH to 9.5, and filter to obtain calcium fluoride, calcium oxide and calcium phosphate The mixed filter residue and lith...

Embodiment 3

[0025] The waste lithium iron phosphate battery was placed in a rotary kiln for indirect reduction roasting, the roasting temperature was controlled at 500°C, and the roasting time was 2h. Use 1mol / L sodium hydroxide solution to spray and absorb the roasting tail gas to F - The concentration is 10.0g / L, and the filter residue containing lithium phosphate and lithium fluoride and the filtrate containing sodium fluoride are obtained by filtration. The filtrate was evaporated and crystallized at 110°C, and filtered immediately when the volume was evaporated to 36% of the volume of the original filtrate, and the obtained filtrate was a crystal of sodium fluoride. Dissolve the filter residue with 6mol / L hydrochloric acid, add calcium oxide 1.3 times the total molar weight of F and P, and at the same time add 3mol / L sodium hydroxide to adjust the pH to 9.0, and filter to obtain calcium fluoride, calcium oxide and calcium phosphate The mixed filter residue and lithium-containing fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com