Plant anti-freezing agent containing organic matters and preparation method thereof

A technology for antifreeze and organic matter, which is applied to the field of plant antifreeze containing organic matter and its preparation, can solve the problems of easy product stratification, high production cost, complicated process, etc., and achieves prevention of drought stress, content reduction, dissolution and penetration. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of a plant antifreeze containing organic matter, comprising the following steps:

[0032] S1. Production of magnetized water: magnetize the water in a 1200mT magnetic field in the magnetizer for 2 hours, and set aside;

[0033] S2, material preparation: Weigh the following raw materials by weight for later use, 60-80 parts of magnetized water, 2-5 parts of antifreeze factor, 3-10 parts of potassium citrate, 3-6 parts of chelating agent, 3-5 parts of plant active substances, 20-50 parts of alcohols, 6-12 parts of sugars, 5-10 parts of functional substances, 2-5 parts of acidity regulators;

[0034] S3. Raw material pulverization: all the solid raw materials in S2 are pulverized and sieved to 150 mesh respectively for later use;

[0035]S4. Add the treated magnetized water into the reaction kettle, control the stirring speed to 60r / min, and the temperature to 45°C, add the antifreeze factor into the reaction kettle, stir for 2 hours, and fully mix; ...

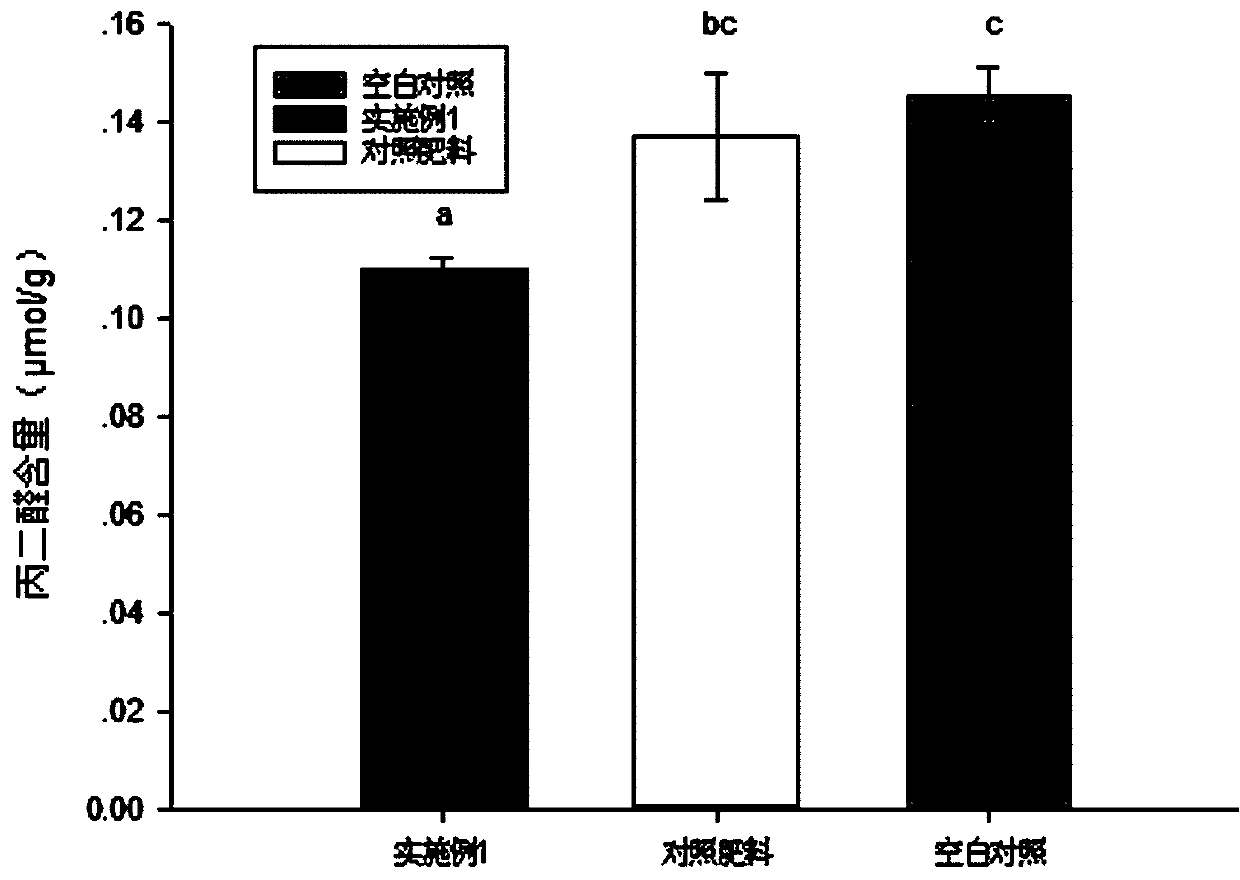

Embodiment 1

[0039] An organic plant antifreeze agent containing organic matter, consisting of the following components and parts by weight: 60 parts of magnetized water, 2 parts of antifreeze factor, 3 parts of potassium citrate, 6 parts of chelating agent, 4 parts of plant active substances, and 20 parts of alcohols , 6 parts of sugar substances, plus 10 parts of functional substances, and 3 parts of acidity regulator.

[0040] In this embodiment, the chelating agent is disodium edetate and tartaric acid, and the mass ratio is: disodium edetate:tartaric acid=4:1.

[0041] In this embodiment, the plant active substance is polyglutamic acid.

[0042] In this embodiment, the alcohols are glycerol and propylene glycol, and the mass ratio is: glycerol:propylene glycol=1:1.

[0043] In this embodiment, the sugar substance is sucrose.

[0044] In this embodiment, the added functional substances are betaine and salicylic acid, according to the mass ratio: betaine:salicylic acid=2:1

[0045] I...

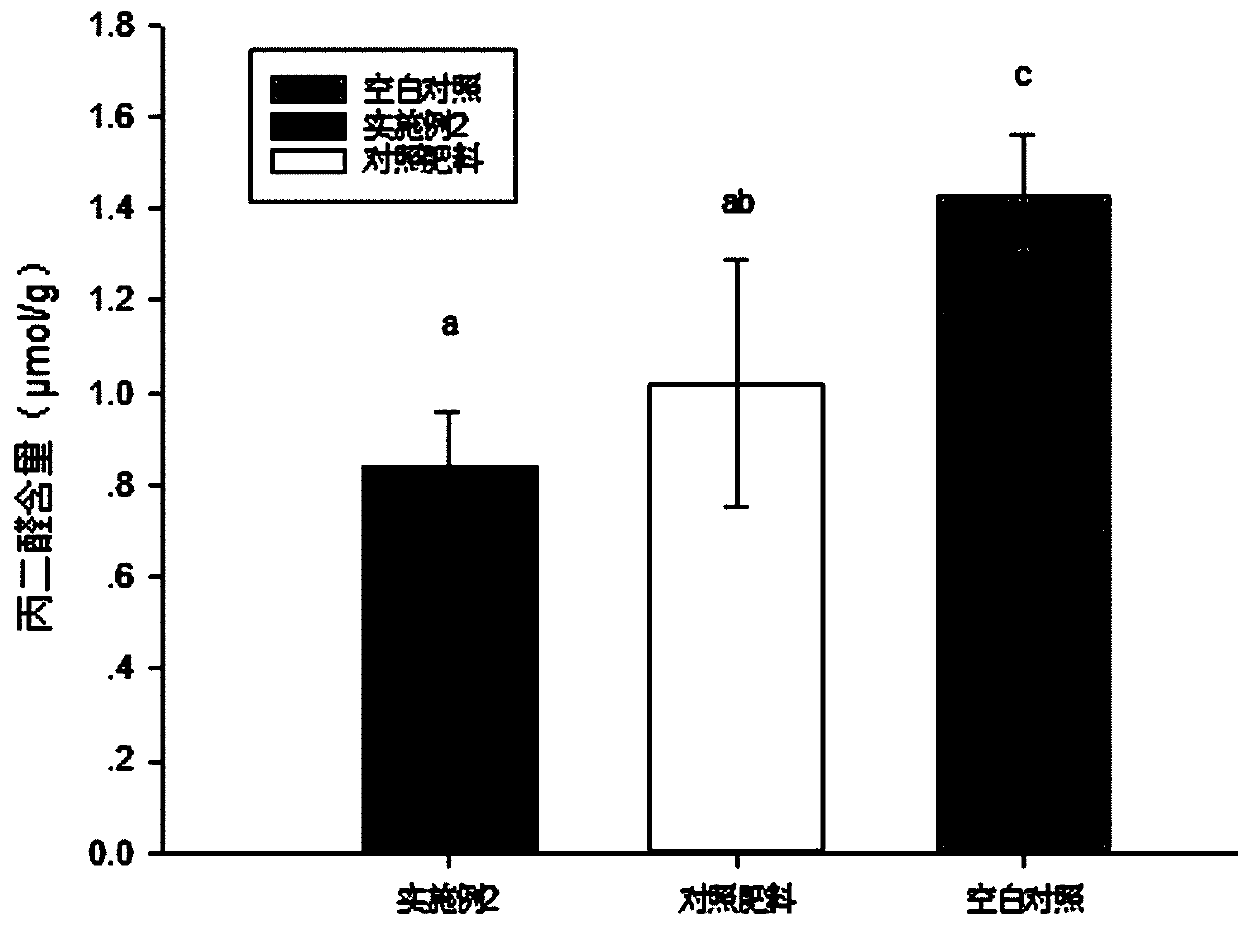

Embodiment 2

[0053] An organic plant antifreeze agent containing organic matter, consisting of the following components and parts by weight: 80 parts of magnetized water, 3 parts of antifreeze factor, 8 parts of potassium citrate, 3 parts of chelating agent, 5 parts of plant active substances, and 40 parts of alcohols , 9 parts of sugar substances, 5 parts of additional functional substances, and 5 parts of acidity regulator. The invention can effectively reduce the freezing point of plants, form a layer of protective film on the surface of plants, and has the functions of water and heat retention without affecting the respiration and photosynthesis of plants.

[0054] The chelating agent is diethylene triamine pentacarboxylate, tartaric acid and sodium gluconate, and the mass ratio is: diethylene triamine pentacarboxylate: tartaric acid: sodium gluconate = 3:2:1.

[0055] The plant active substance is sodium alginate.

[0056] The alcohols are glycerol and sorbitol, and the mass ratio is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com