Preparation method for PVDF/GBT composite bone scaffold

A bone scaffold and composite powder technology, applied in medical science, tissue regeneration, prostheses, etc., can solve the problem of poor interface bonding between nanoparticles and polymer matrix, difficulty in strengthening piezoelectric and mechanical properties of materials, and piezoelectricity of composite materials. Performance can not be enhanced and other problems, to achieve the effect of improving electromechanical coupling efficiency, enhancing interface compatibility, and enhancing interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

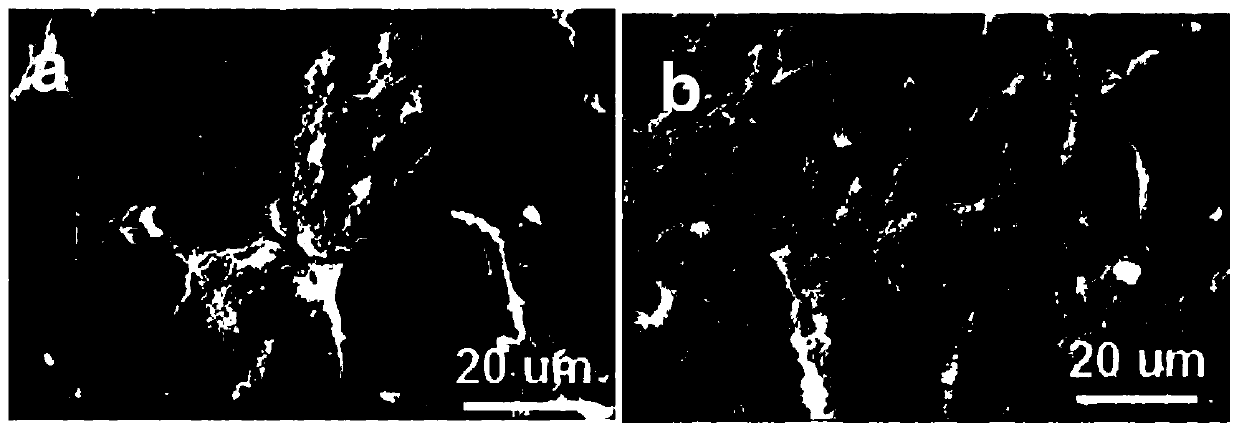

Image

Examples

Embodiment 1

[0047] (1) 2 g of dopamine hydrochloride powder was weighed with an electronic balance, and added to 10 mM Tris-HCL buffer solution to prepare 1 L of 2.0 mg / mL dopamine solution.

[0048] (2) Use an electronic balance to weigh 5g of BaTiO with a particle size of 200nm 3 Add the powder into the above-mentioned dopamine solution, and disperse evenly through mechanical stirring and ultrasound. The main process parameters are: dopamine polymerization reaction time is 5h, mechanical stirring speed is 80r / min; reaction temperature is 60°C, pH is 7, and then The obtained suspension was filtered and washed with deionized water to remove unreacted dopamine monomer on the surface; vacuum-dried at 60° C. for 12 hours to obtain polydopamine-modified barium titanate powder.

[0049] (3) Weigh 1 g of DBT powder with an electronic balance, add it into a three-necked flask filled with anhydrous ethanol solution, and realize its pre-dispersion by mechanical stirring and ultrasonic dispersion. ...

Embodiment 2

[0056] (1) 2 g of dopamine hydrochloride powder was weighed by an electronic balance, and added to 10 mM Tris-HCL buffer solution to prepare a 2.0 mg / mL dopamine solution.

[0057] (2) Weigh 5g of BaTiO with a particle size of 400nm using an electronic balance 3 Add the powder into the above-mentioned dopamine solution, and disperse evenly through mechanical stirring and ultrasound. The main process parameters are: the dopamine polymerization reaction time is 5h, the mechanical stirring speed is 80r / min; The suspension was filtered and washed with deionized water to remove unreacted dopamine monomer on the surface; vacuum-dried at 60° C. for 12 hours to obtain polydopamine-modified barium titanate powder.

[0058] (3) Weigh 2 g of DBT powder with an electronic balance, add it into a three-necked flask filled with anhydrous ethanol solution, and realize its pre-dispersion by mechanical stirring and ultrasonic dispersion.

[0059] (4) Use an electronic balance to weigh 8g of PV...

Embodiment 3

[0065] (1) 2 g of dopamine hydrochloride powder was weighed by an electronic balance, and added to 10 mM Tris-HCL buffer solution to prepare a 2.0 mg / mL dopamine solution.

[0066] (2) Utilize the electronic balance to weigh 5g of powders with a particle diameter of 400nm, join in the above-mentioned dopamine solution, and disperse evenly through mechanical stirring and ultrasonic waves. The main process parameters are: the dopamine polymerization reaction time is 5h, and the mechanical stirring speed is 80r / min; the reaction temperature is 50°C, the pH is 9, and then the obtained suspension is filtered and washed with deionized water to remove the unreacted dopamine monomer on the surface; vacuum-dried at 60°C for 12 hours to obtain polydopamine-modified titanium Barium Oxide powder.

[0067] (3) Weigh 0.5 g of DBT powder with an electronic balance, add it into a three-necked flask filled with anhydrous ethanol solution, and realize its pre-dispersion by mechanical stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com